Екструдер для компаундування

Here you can find different extruders for different applications, we have parallel twin screw extruders, three screws extruders, laboratory extruders, double stage extruders, single screw extruders etc.

-

Laboratory Twin Screw Extruder

When will you need a lab twin screw extruder? If you want to make trials and tests of your formula before the big production, then you need a laboratory twin screw extruder. Such as polymer materials, color masterbatches, engineering plastics, functional masterbatches, elastomers, etc. Advantages of our lab extruder Main technical parameter Model D【mm】 【mm】 【rpm】…

-

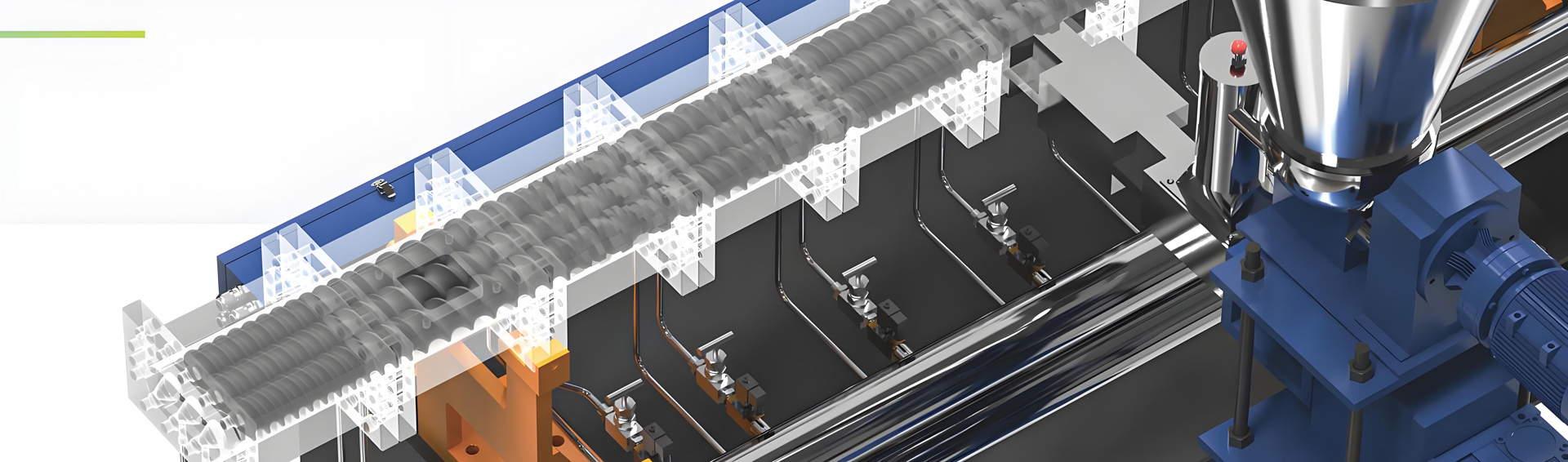

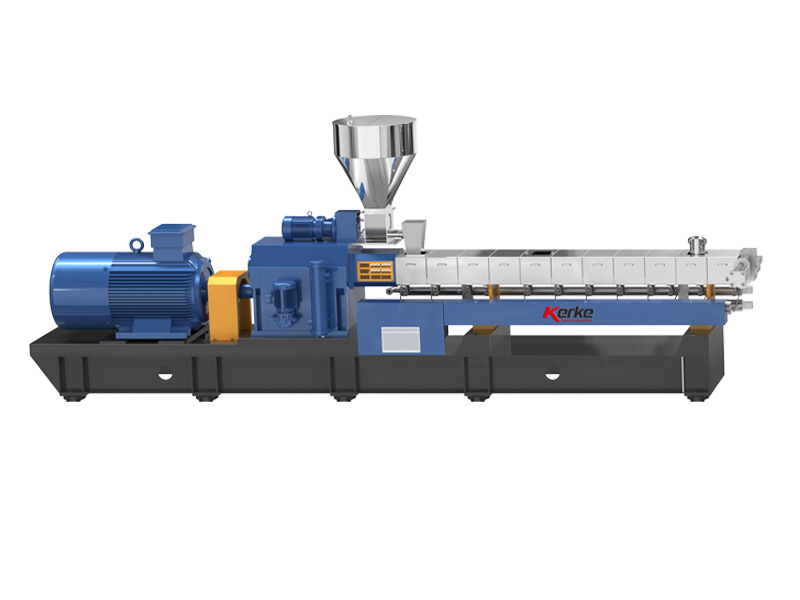

Parallel Twin Screw Extruder

Our Parallel Co-rotating twin screw extruder is designed for compounding and masterbatch making with an output capacity from 30kg/h to 4000kg/h. Why should you choose Kerke twin screw extruder? When considering an investment in industrial equipment, particularly in the realm of polymer processing, the choice of machinery can significantly impact the efficiency, quality,…

-

Triple (3 screws) Extruder

3 Screws extruder is a new technology that has many advantages. The triple screw extruder is mainly used for special applications with good dispersion and higher output Why 3 screws extruder? 3 screw extruder has some advantages for special applications, parallel twin screw extruder was a long-time technology, but for some special applications the twin…

-

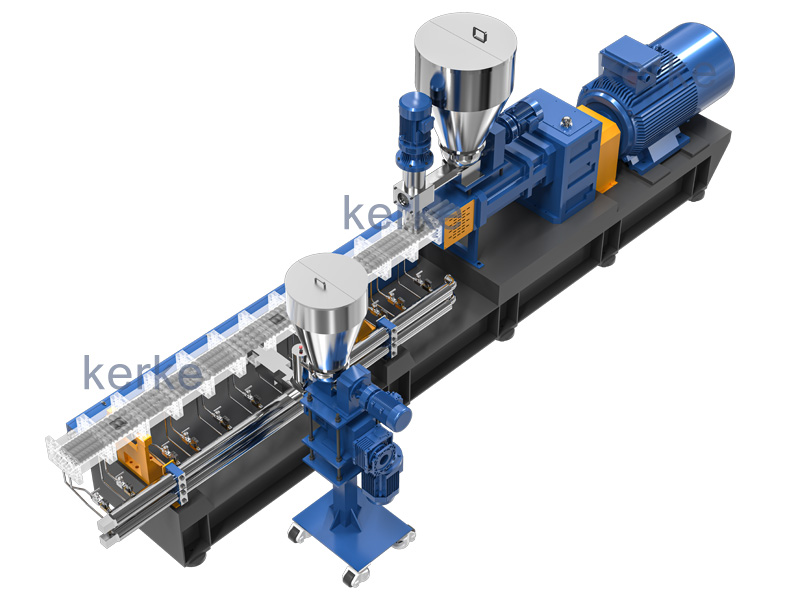

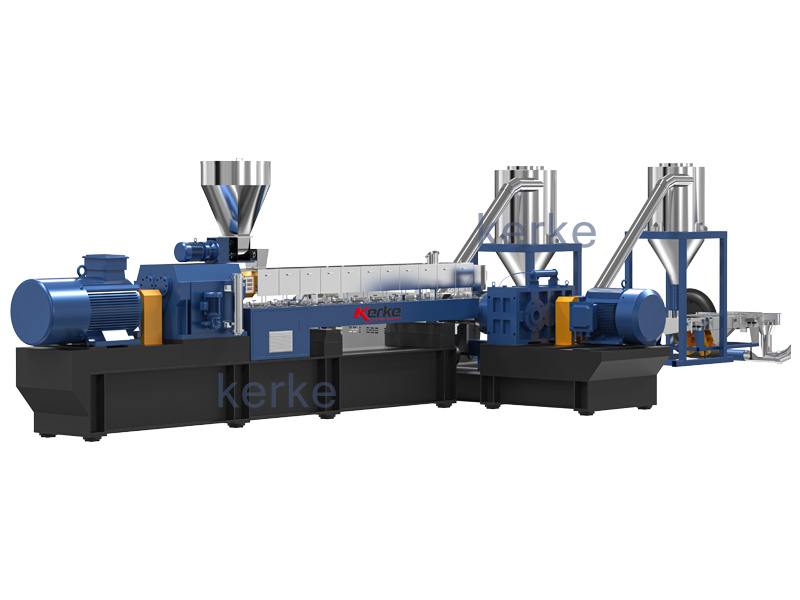

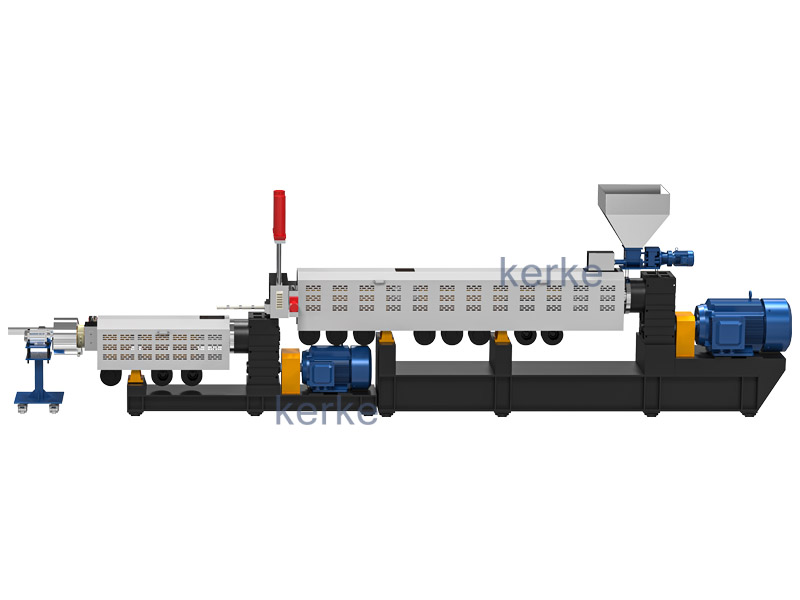

Double-Stage Extrusion System

Mother-baby extrusion system is designed for special materials which can not process on one stage extruder, the first stage is a twin screw extruder, and the second stage is a single screw extruder. When you should use a double-stage extruder? If your material needs special dispersion but not over shear like the cable…

-

Banbury Kneader Compounding Line

Our kneader + extruder is designed for making special applications with an output capacity from 30kg/h to 1000kg/h. When should you choose the kneader? Kneader reactor technology has long been used for what is known as “Process Intensification”, where multiple processing steps are performed in the same unit. Such units are characterized by…

-

3D Printing Filament Extrusion Line

3D printing filament is the thermoplastic feedstock for fused deposition modeling 3D printers. There are many types of filament available with different properties. Filament comes in a range of diameters, most commonly 1.75 mm and 3.0 mm, with the latter often being confused with the less common 3 mm. The filament consists of one continuous slender plastic thread spooled into a reel.…

-

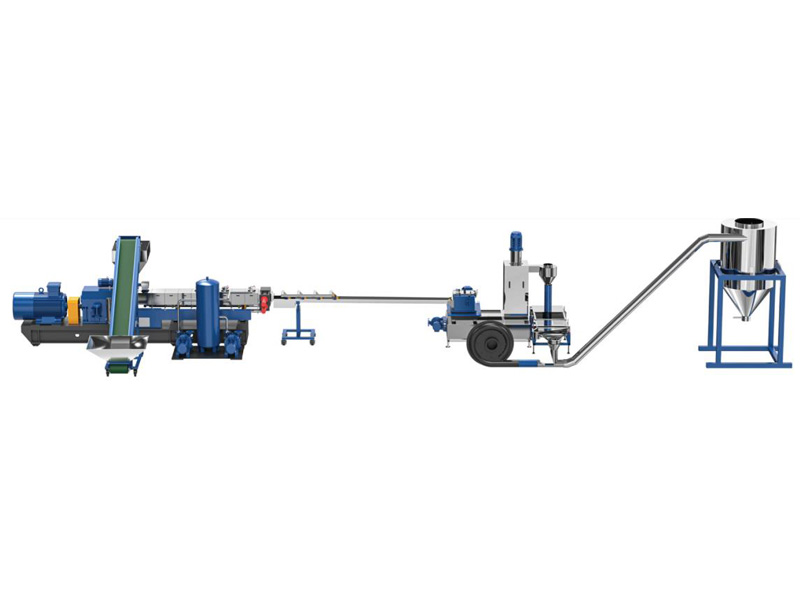

Single Screw Extruder

Our single screw extruder is mainly used for plastic recycling with an output capacity from 30kg/h to 800kg/h. When you should use a single screw extruder? If you want to recycle waste plastic into pellets, a single-screw extruder is better than a twin screw extruder. Our engineer will design the most suitable single extruder…

-

Cutting System / Pelletizing System

Different material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of each cutting system 1. Water Cooling Strands Cutting (Spaghetti type) This is the common and frequently-used cutting type, the strands (spaghetti) come from the die head then into the water cooling tub, then the air…

Plastic Sheet Extrusion Line

We use a twin screw extruder which can make compounding and sheet extruder in one step, not like the single extruder, you should make compounded granules, then make the sheet. Because we use a one-step sheet-making process, it can save much energy. You can save more money on machine and materials purchasing.

-

Екструзійна лінія для виготовлення плівки PVB

PVB Glass Interlayer film is mainly used for making interlayer safety glass and the application of safety glass is also very widely used. In the auto industry, PVB film is the main material for making windshield glass. The PVB Glass Interlayer Film is also used widely in the construction industry because of its characteristics…

-

Екструзійна лінія для виготовлення листів з ПЕТ/ПЕТ-пластику

Twin screw extruder has unique merits to the process of polyester resins. Polyester is very vulnerable to thermal decomposition and hydrolyzation. Kerke has launched a newly high-tech, lower-shearing, and low-temperature twin screw extruder for the PET process, which streamlined the process, and portrayed advantages in energy-saving and end product quality. As a result, the…

-

Екструзійна лінія для виготовлення листів TPU/TPO/EVA

Elastomer material sheet extrusion needs a special extruder design, Our Parallel Co-rotating twin screw extruder is designed for TPU/TPO/EVA sheet production with an output capacity from 300kg/h to 1000kg/h. Why should you choose our twin screw extruder? With over 13 years of experience in twin screw extruder manufacturing, our customers cover over 70 countries, and…

Plastic Extruder Auxiliary Equipments

With our experience in compounding extruders, Kerke can provide the twin screw extruder auxiliary equipment to customers. Such as the high-speed mixer, the plastic granulator, the pulverizer, the extruder core parts, and the water chiller.

-

Високошвидкісний змішувач

As the core part of the compounding and masterbatch production process, the high-speed mixer is for premixing all raw materials, Our mixer volume from 5L to 2000L, high-speed mixer, and hot-cold double-stage mixer. High-Speed Mixer Parameters Model SHR-5A SHR-50A SHR-100A SHR-200A SHR-300A SHR-500A SHR-800A SHR-1000A Total Volume 5L 50L 100L 200L 300L 500L…

-

Plastic Pelletizer Machine (Strand Type)

The plastic pelletizer machine is a very important part of the compounding extruder (spaghetti type), but how to choose a suitable plastic pelletizer machine is not easy, Kerke can provide the pelletizer machine from 1kg/h to 2000kg/h, we have the standard type and high standard type, the pellets size can be from 3mmx5mm…

-

Plastic Pulverizer / Mill Machine

Our pulverizer machine is designed for compounding and masterbatch making with an output capacity from 30kg/h to 500kg/h. Mainly materials Main technical parameter Model SMW-400 SMW-500 SMW-600 SMW-800 Vacuum loader (Optional) 1.5KW 1.5KW 1.5KW 1.5KW Motor power 30KW 37KW 45KW 75KW Milling chamber Φ400mm Φ500mm Φ600mm Φ800mm Grinding disc 1 set(one rotary blade, one fixed…

-

Чиллер з водяним охолодженням

A water chiller is an essential part of the extrusion machine, Kerke can provide a high-quality water chiller at a good price. We have air cooled chiller and water cooled chiller. Main technical parameter (Air cooled) Model 8P 10P 12P 15P 20P Cooling capacity 19.9 Kw17157 Kcal/h 24.95 Kw21457 Kcal/h 28.5 Kw24570 Kcal/h…

-

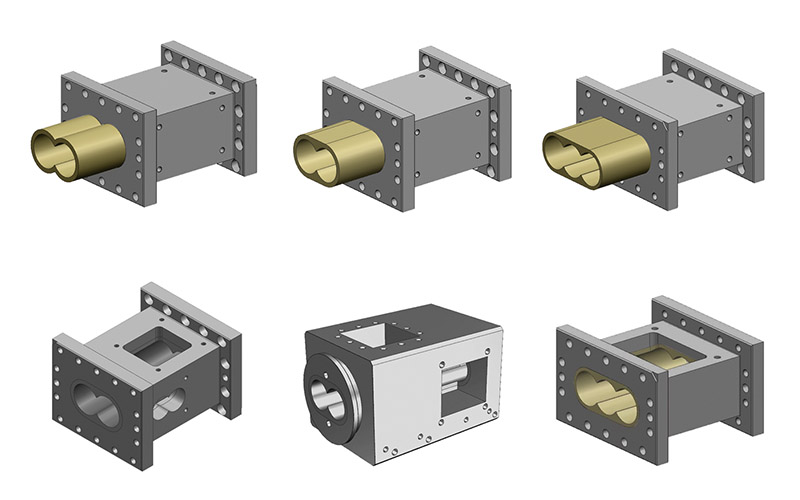

Частини екструдера

Kerke started from the extruder parts trade, then we have our factory to produce screw elements and sell to extruder factories, in 2009, we started to produce extruders by ourselves. Now many other manufacturers still buy core parts from outside, but we still insist on producing core parts by ourselves, because we can…