Kerke started from the extruder parts trade, then we have our factory to produce screw elements and sell to extruder factories, in 2009, we started to produce extruders by ourselves. Now many other manufacturers still buy core parts from outside, but we still insist on producing core parts by ourselves, because we can control the quality and send all parts to our customers fast.

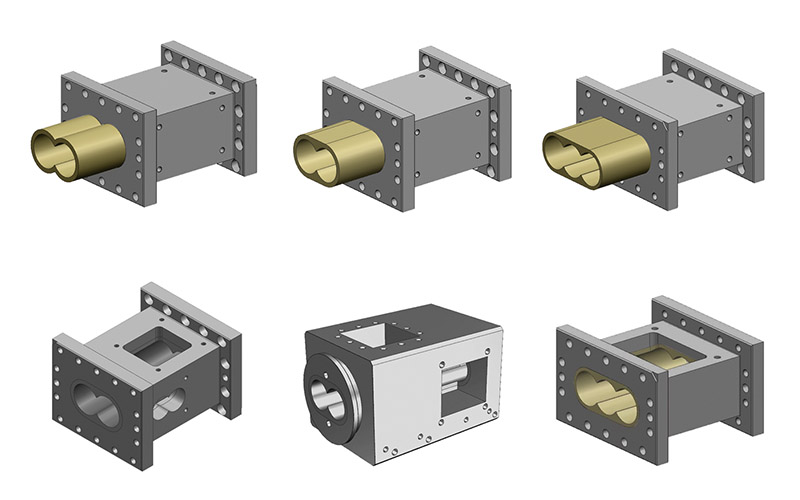

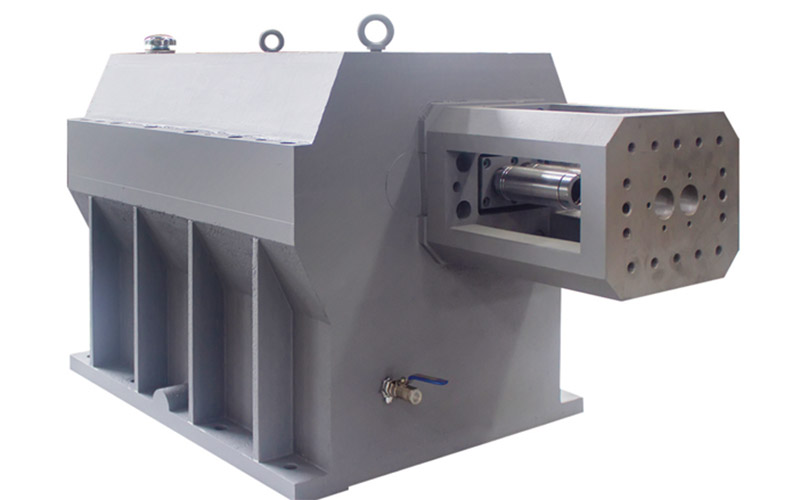

Extruder Reduction Gearbox

We can provide types of gearbox, speed from 200rpm to 900rpm, and torque from 5.5N.m to 13N.m.

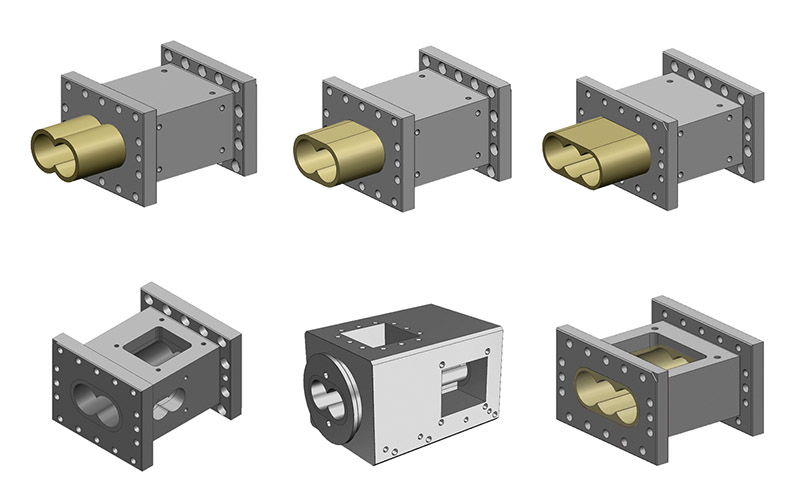

Extruder Barrel

The barrel body is made of #45 steel matrix (C type and full type sleeve).

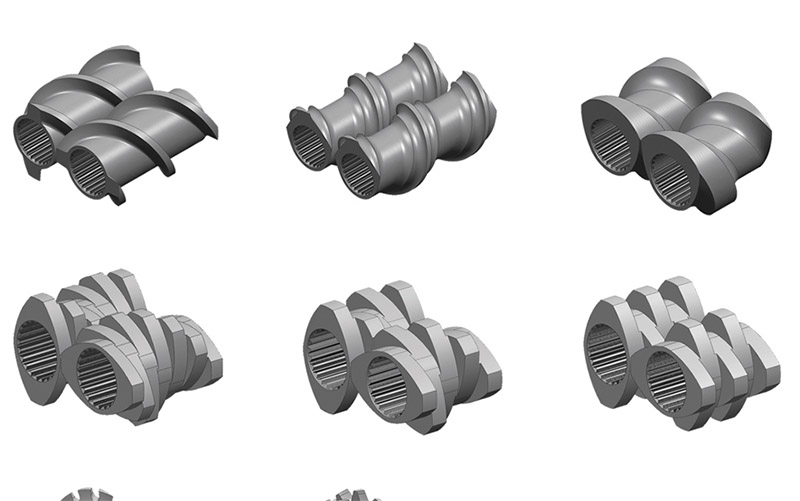

Screw Element

Our normal screw elements adopt high-speed tool steel, W6Mo5Cr4V2. Heat treatment rigidity = HRC60-64; Screw component connect to axes by involute spline.