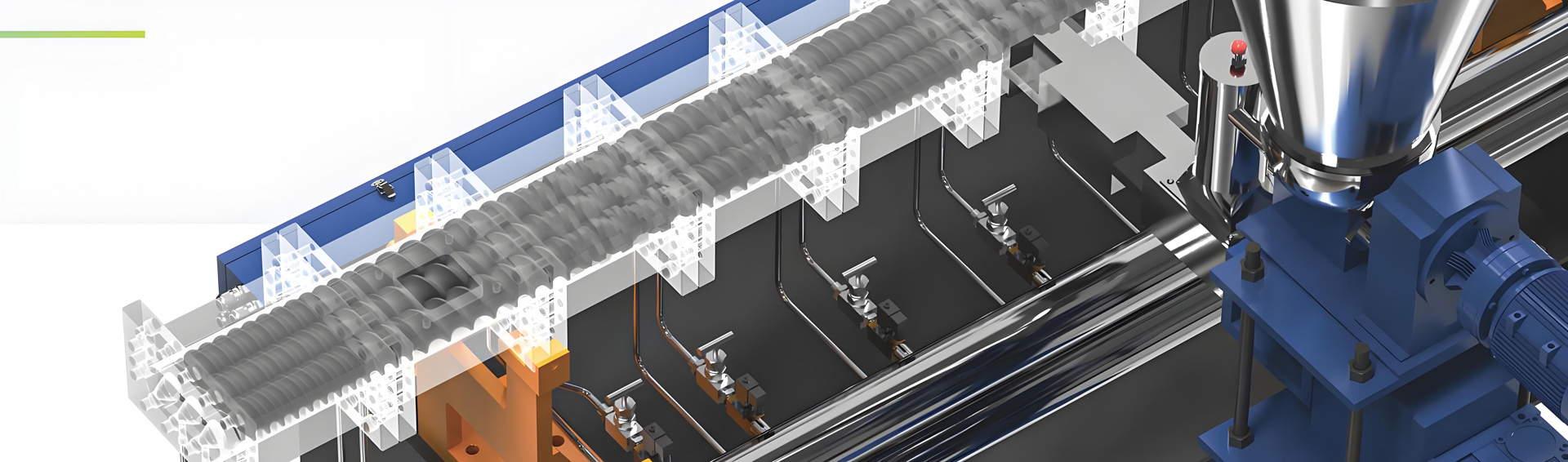

Plastic sheet and plastic film extruders heat the molten material, push it to the die by the rotation of the screw, and extrude it through the mold. Specifically, the solid plastic is heated to liquid state, then pushed to the mold by the screw, and finally cooled and shaped to obtain the desired shape of plastic sheet or plastic film. It can be used to produce various types of plastic sheets and plastic films, such as products made of polyethylene, polypropylene, polyvinyl chloride and other materials.

-

PVB Film Extrusion Line

PVB Glass Interlayer film is mainly used for making interlayer safety glass and the application of safety glass is also very widely used. In the auto industry, PVB film is the main material for making windshield glass. The PVB Glass Interlayer Film is also used widely in the construction industry because of its characteristics…

-

PET/R-PET Sheet Extrusion Line

Twin screw extruder has unique merits to the process of polyester resins. Polyester is very vulnerable to thermal decomposition and hydrolyzation. Kerke has launched a newly high-tech, lower-shearing, and low-temperature twin screw extruder for the PET process, which streamlined the process, and portrayed advantages in energy-saving and end product quality. As a result, the…

-

TPU/TPO/EVA Sheet Extrusion Line

Elastomer material sheet extrusion needs a special extruder design, Our Parallel Co-rotating twin screw extruder is designed for TPU/TPO/EVA sheet production with an output capacity from 300kg/h to 1000kg/h. Why should you choose our twin screw extruder? With over 13 years of experience in twin screw extruder manufacturing, our customers cover over 70 countries, and…

To provide you with the world’s

leading extrusion equipments

19997+

Square Meters of Our Factory

2000+

Machines Running Worldwide

70+

Countries of Our Customer

100+

Numbers of Our Team