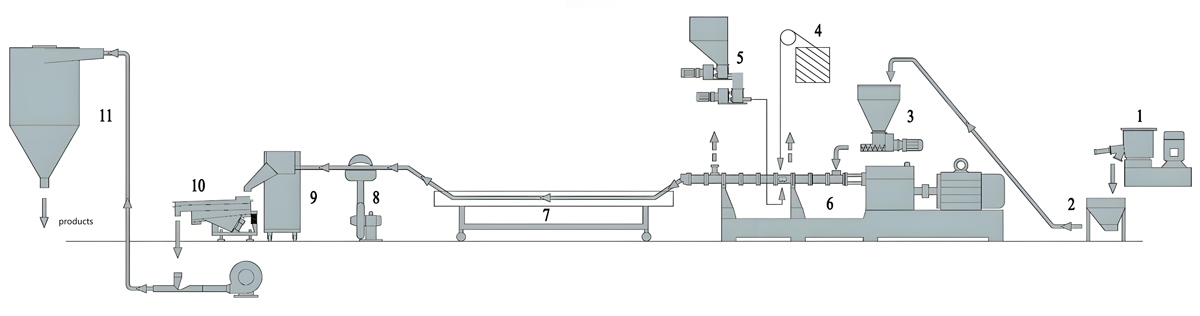

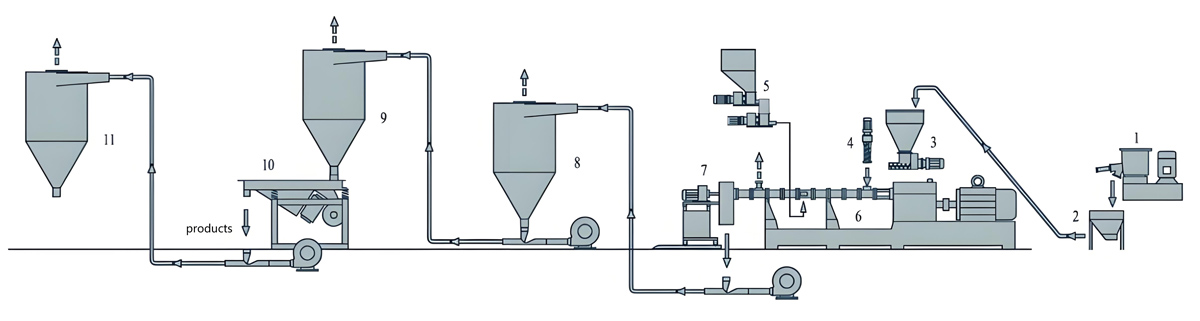

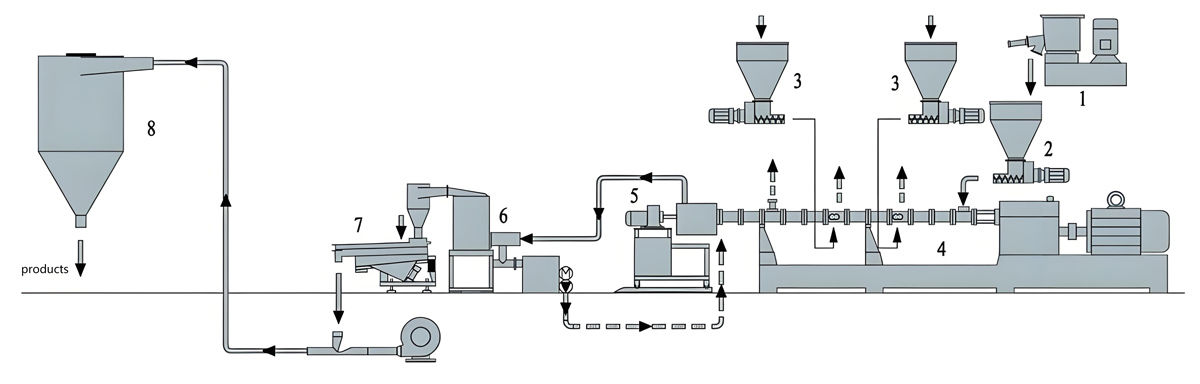

Our kneader + extruder is designed for making special applications with an output capacity from 30kg/h to 1000kg/h.

- Filler Masterbatch (Caco3 Over 85%)

- Black Masterbatch (Carbon Black Over 50%)

- Cable Application

- others

When should you choose the kneader?

Kneader reactor technology has long been used for what is known as “Process Intensification”, where multiple processing steps are performed in the same unit. Such units are characterized by high yield per performance volume and also have the flexibility to produce different grades and/or products. We only focus on plastic applications, especially for thermoplastic applications like TPU/TPE/TPO/EVA/TPR/PVC and high-filled masterbatch like Caco3 filler (Caco3 over 85%), carbon black masterbatch (carbon black over 50%), cable application, etc

Advantages of Kneader

- Excellent mixing and kneading performance during wet, pasty, and viscous phases

- Compact design maximizing process yield per performance volume and minimizing space requirement

- Narrow residence-time distribution for plug flow operation

- Maximum self-cleaning

- Large heat-exchange surface areas yielding the highest possible surface-to-volume ratio

Kerke Kneader Parameters

| Model | 35L | 55L | 75L | 110L |

| Effective mixing volume | 35L | 55L | 75L | 110L |

| Power | Main motor:55KW,6P;Rotating motor:1.5KW,4P | Main motor:75KW,6P;Rotating motor:2.2KW,4P | Main motor: 110KW,6P;Rotating motor:3.75KW,4P | Main motor: 160KW,6P;Rotating motor:5.5KW,4P |

| The speed of the rachis | Front axle 39rpm, back shaft 30rpm, | Front axle 39rpm, back shaft 30rpm, | Front axle 39rpm, back shaft 30rpm, | Front axle 39rpm, back shaft 30rpm, |

| Feeding mode | Front / back feed | Front / back feed | Front / back feed | Front / back feed |

| Discharging mode | Turning type unloading | Turning type unloading | Turning type unloading | Turning type unloading |

| Seal way | Mechanical forced tight seal | Mechanical forced tight seal | Mechanical forced tight seal | Mechanical forced tight seal |

| Temperature mode | With water cooling, controlled by digital display automatic temperature controller, higher than the set temperature, automatic cooling | With water cooling, controlled by digital display automatic temperature controller, higher than the set temperature, automatic cooling | With water cooling, controlled by digital display automatic temperature controller, higher than the set temperature, automatic cooling | With water cooling, controlled by digital display automatic temperature controller, higher than the set temperature, automatic cooling |

| Single batch processing time | About 4~7 batches per hour | About 4~7 batches per hour | About 4~7 batches per hour | About 4~7 batches per hour |

| Single batch production | About 26-45kg per batch | About 45-75kg per batch | About 60-85kg per batch | About 100-140kg per batch |

| Capacity | 200-300Kg/h | 300-450Kg/h | 350-550Kg/h | 600-850Kg/h |