Kerke, with over 13 years of experience, provides not only high-quality compounding extruders but also good prices and service. You can receive 3 excellent items from Kerke. Excellent Pre-sales Service; Excellent Quality and Price; Excellent After-sale Service.

-

Laboratory Twin Screw Extruder

When will you need a lab twin screw extruder? If you want to make trials and tests of your formula before the big production, then you need a laboratory twin screw extruder. Such as polymer materials, color masterbatches, engineering plastics, functional masterbatches, elastomers, etc. Advantages of our lab extruder Main technical parameter Model D【mm】 【mm】 【rpm】…

-

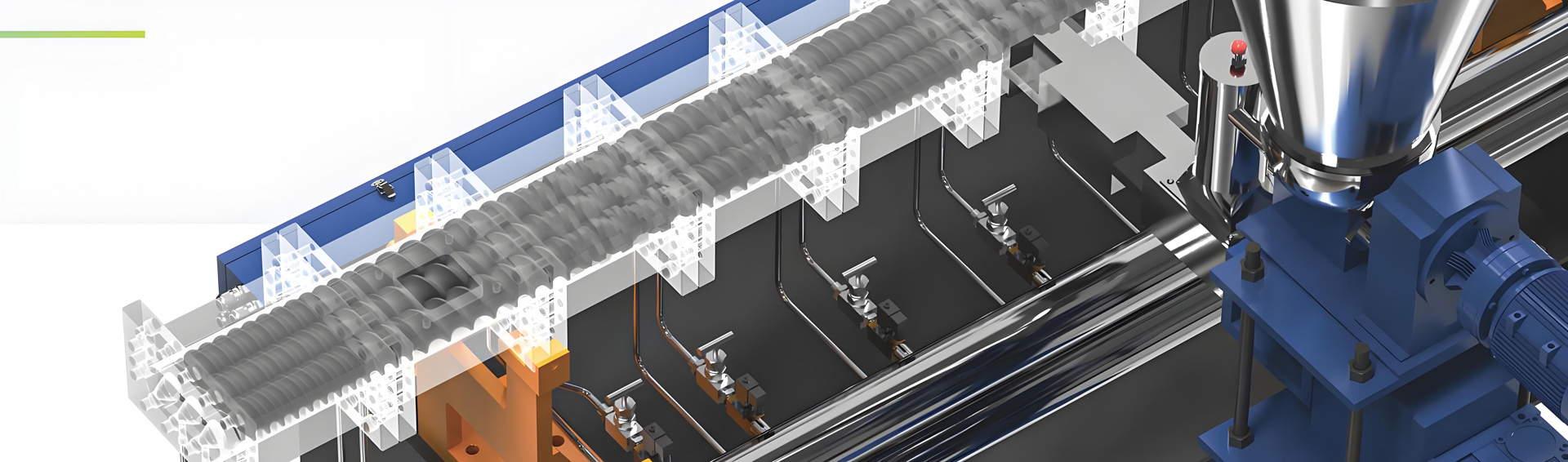

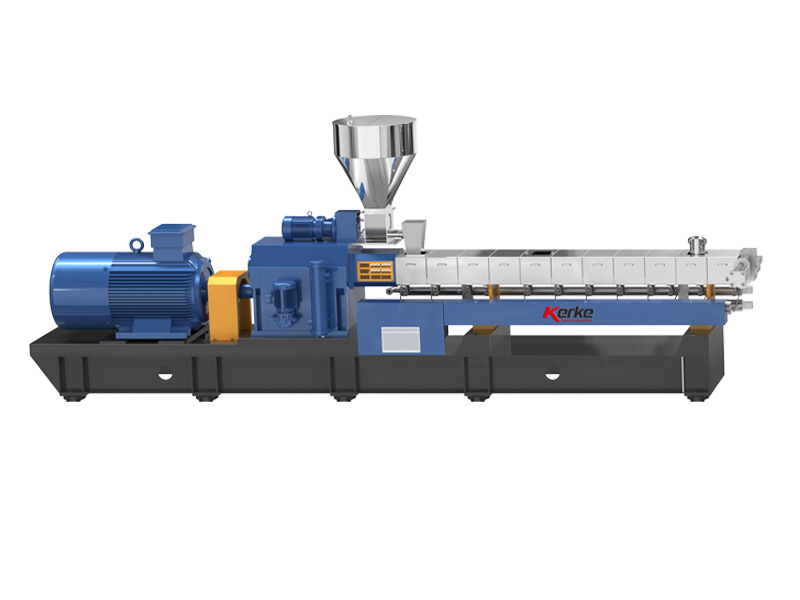

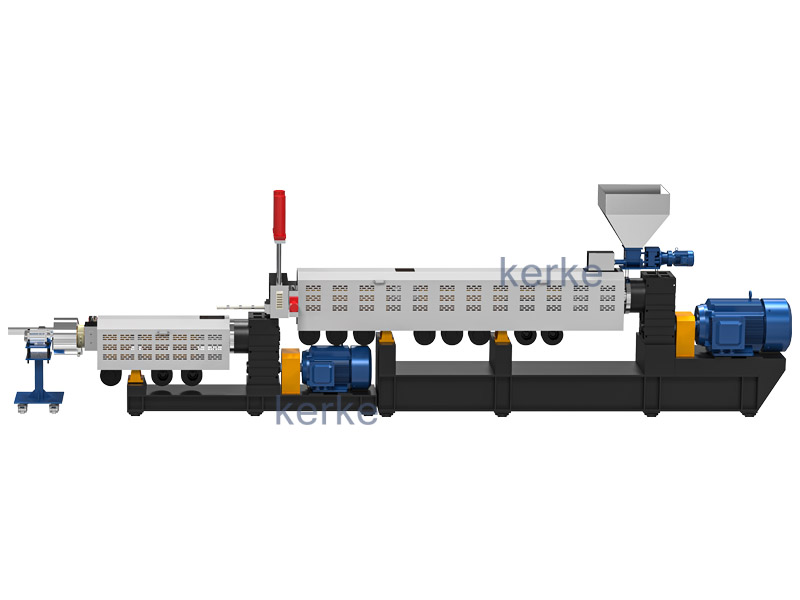

Parallel Twin Screw Extruder

Our Parallel Co-rotating twin screw extruder is designed for compounding and masterbatch making with an output capacity from 30kg/h to 4000kg/h. Why should you choose Kerke twin screw extruder? When considering an investment in industrial equipment, particularly in the realm of polymer processing, the choice of machinery can significantly impact the efficiency, quality,…

-

Triple (3 screws) Extruder

3 Screws extruder is a new technology that has many advantages. The triple screw extruder is mainly used for special applications with good dispersion and higher output Why 3 screws extruder? 3 screw extruder has some advantages for special applications, parallel twin screw extruder was a long-time technology, but for some special applications the twin…

-

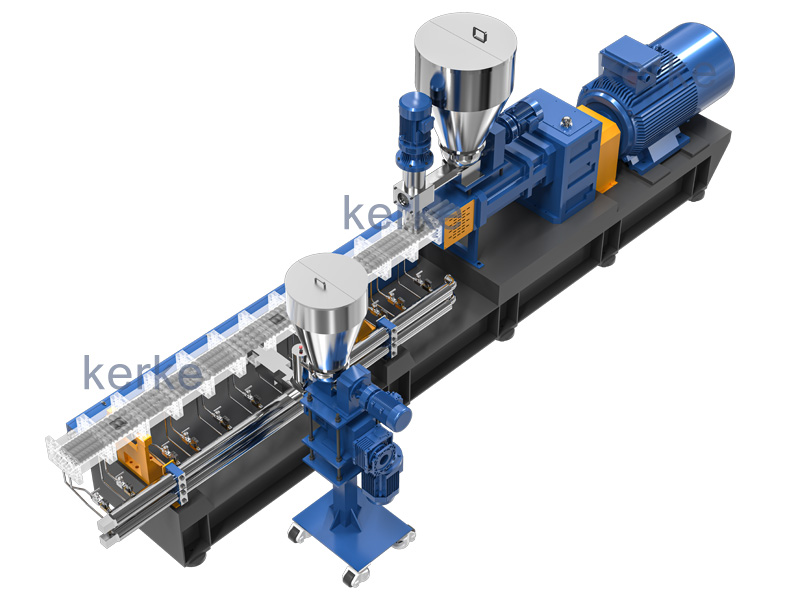

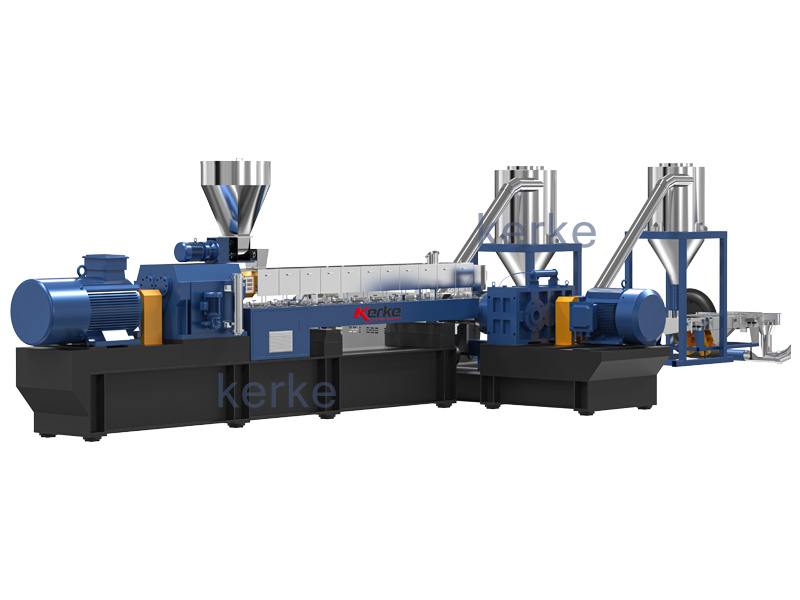

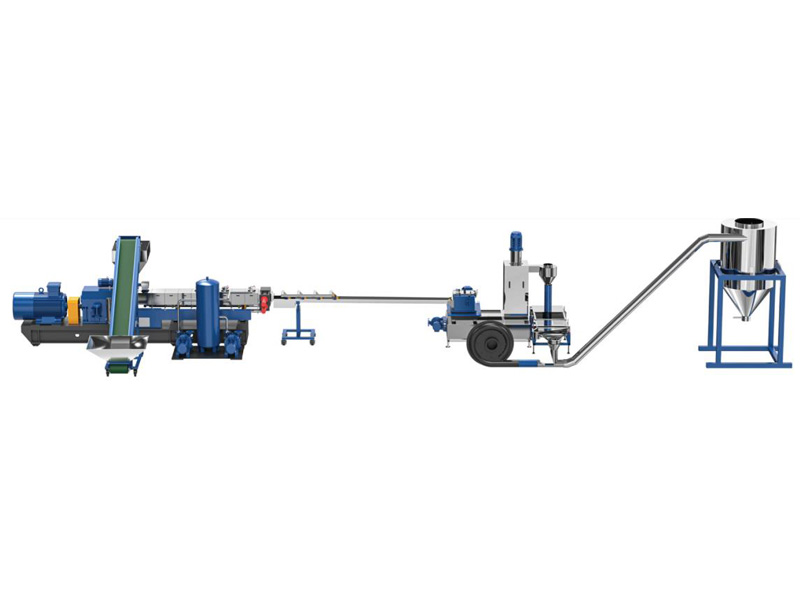

Double-Stage Extrusion System

Mother-baby extrusion system is designed for special materials which can not process on one stage extruder, the first stage is a twin screw extruder, and the second stage is a single screw extruder. When you should use a double-stage extruder? If your material needs special dispersion but not over shear like the cable…

-

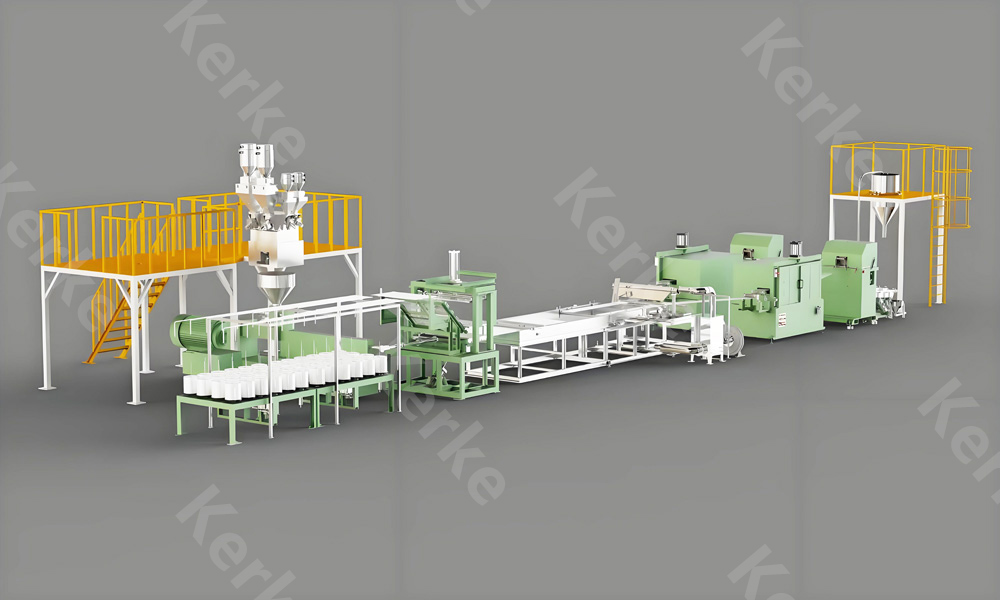

Banbury Kneader Compounding Line

Our kneader + extruder is designed for making special applications with an output capacity from 30kg/h to 1000kg/h. When should you choose the kneader? Kneader reactor technology has long been used for what is known as “Process Intensification”, where multiple processing steps are performed in the same unit. Such units are characterized by…

-

LFT-G Extruder Line

Long glass fiber reinforced thermoplastic composites (LFT-G) are composed of long glass fibers and thermoplastic resins. LFT-G has the characteristics of high strength and high rigidity. The fibers bear most of the load, which can give the composites high modulus, high strength, high toughness and other properties. It has good dimensional stability, can…

-

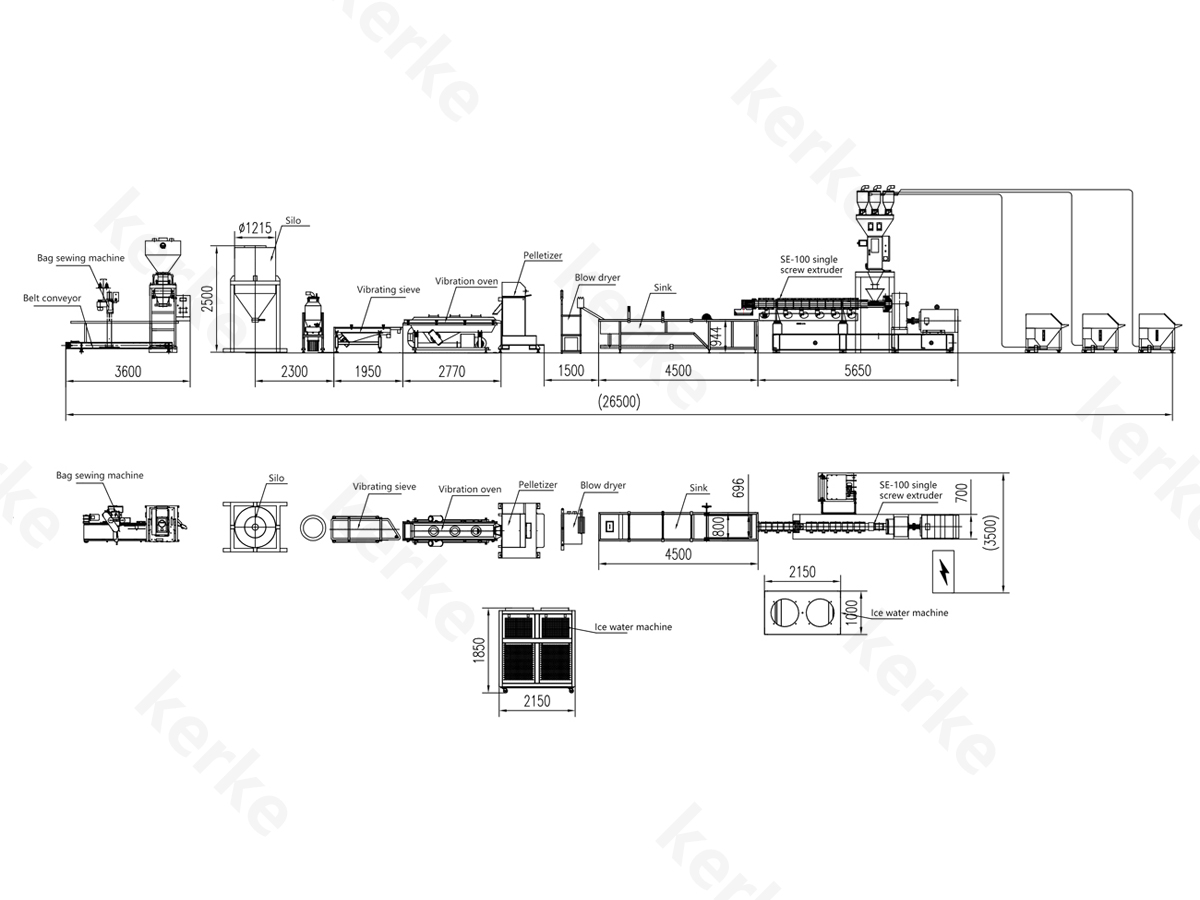

Micro Pellet Extruder Line

The SE-100 single screw extruder is the core part of the production line, which consists of a bracket, a drive group and a screw extruder body. The drive group drives the SE-100 single screw extruder body to operate. The extruder body includes an outer barrel, a screw group and a discharge mechanism, which…

-

3D Printing Filament Extrusion Line

3D printing filament is the thermoplastic feedstock for fused deposition modeling 3D printers. There are many types of filament available with different properties. Filament comes in a range of diameters, most commonly 1.75 mm and 3.0 mm, with the latter often being confused with the less common 3 mm. The filament consists of one continuous slender plastic thread spooled into a reel.…

-

Single Screw Extruder

Our single screw extruder is mainly used for plastic recycling with an output capacity from 30kg/h to 800kg/h. When you should use a single screw extruder? If you want to recycle waste plastic into pellets, a single-screw extruder is better than a twin screw extruder. Our engineer will design the most suitable single extruder…

-

Cutting System / Pelletizing System

Different material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of each cutting system 1. Water Cooling Strands Cutting (Spaghetti type) This is the common and frequently-used cutting type, the strands (spaghetti) come from the die head then into the water cooling tub, then the air…

Main Applications of Our Compounding Extruder

You can find a suitable extruder for your industries, We provide the turn-key solution for your business. Feel free to contact our sales engineer.

-

Color Masterbatch Compound

A color masterbatch, or color concentrate, is a granule used for coloring thermoplastics. It consists of one or more colorants and a polymer-specific carrier resin. The composition of a color masterbatch is called its recipe. Colorants are classified into several categories: organic dyes, organic pigments, and inorganic pigments. Dyes are soluble in plastics and…

-

Filler Masterbatch Compound

As our main application, Kerke extruder can process kinds of filler masterbatch from 60% to 95% with good dispersion and higher output. What are the advantages of filler masterbatch? So, how exactly do plastic firms benefit from filler masterbatch? Mainly Filler: Filler Masterbatch Production

-

Additives Masterbatch Compound

Additive Masterbatches consist of a concentrated mixture of pigments and/or encapsulated additives manufactured through a process of heating a carrier resin and then cooled and cut into a granular form. Our compounding extruder can make excellent additive masterbatches. Main Additives Masterbatch

-

Black Masterbatch Compound

Black Masterbatch is widely used in industrial plastic products, through producing processes like extrusion molding, blown film, blown molding, pipe extruder, etc. Its everyday applications are making car plastic parts, agricultural plastic mulching, garbage bags, or HDPE pipes. The intention of using Black Masterbatch is to add black color to plastic goods. There are…

-

Textile Masterbatch Compound

We provide a specially designed twin screw extruder for processing a variety of polymer solutions to meet the needs of the PP& PET fibers. We gladly satisfy our customers by offering solutions for technical issues and providing them with standard and tailor-made colors. Our experience gained over the years enables us to perform…

To provide you with the world’s

leading extrusion equipments

19997+

Square Meters of Our Factory

2000+

Machines Running Worldwide

70+

Countries of Our Customer

100+

Numbers of Our Team