Polyethylene (PE) modified masterbatch refers to a polymer material with special properties prepared by adding a certain amount of modifiers (such as antibacterial agents, anti adhesive agents, flame retardants, etc.) and other additives to polyethylene resin through specific processing techniques (such as mixing, melting, extrusion, etc.). According to the different types of modifiers added, polyethylene modified masterbatch can be divided into various types, such as antibacterial PE masterbatch, anti adhesive PE masterbatch, flame-retardant PE masterbatch, etc.

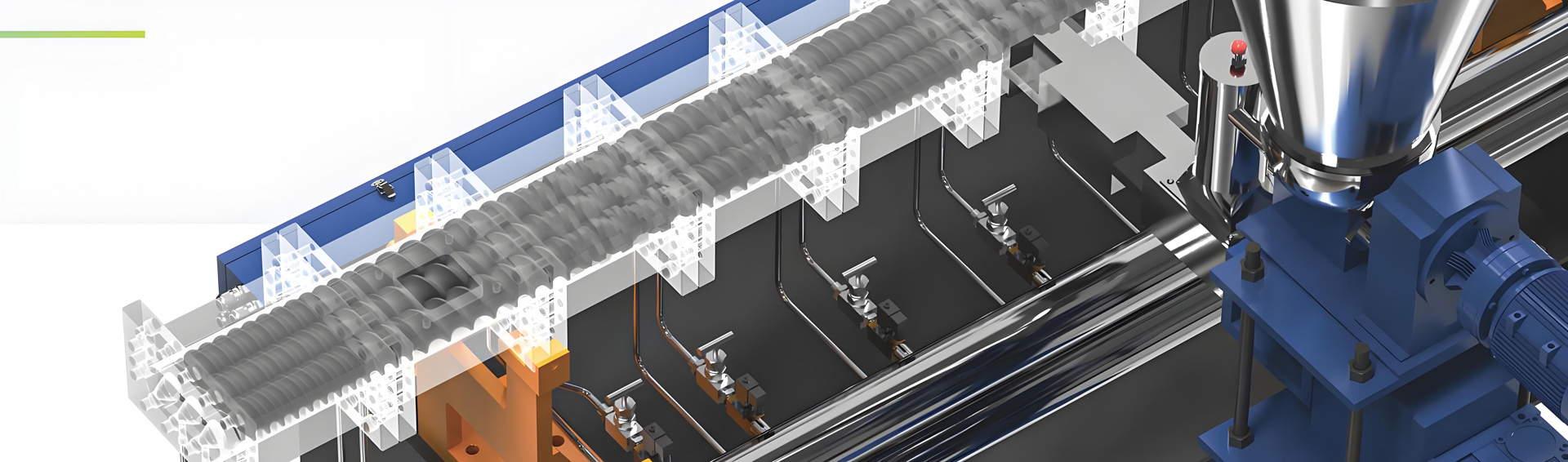

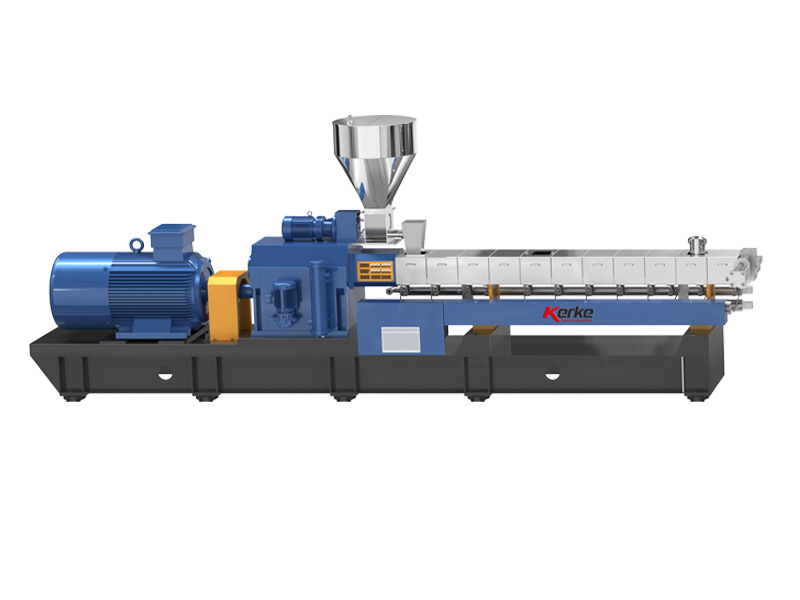

Polyethylene modified masterbatch extruder

Kerke’s masterbatch extruder can be used to produce polyethylene modified masterbatch. Our masterbatch extruder has multiple models to choose from, which can meet different production requirements.

-

Laboratory Twin Screw Extruder

When will you need a lab twin screw extruder? If you want to make trials and tests of…

-

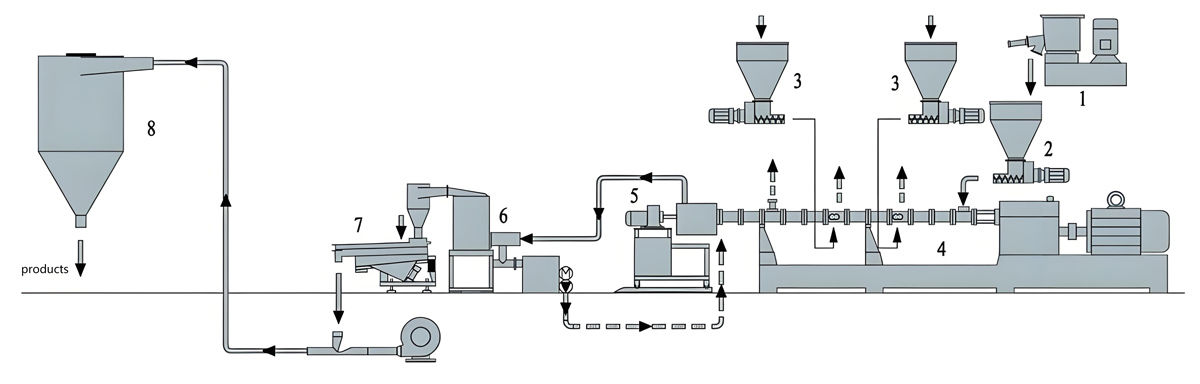

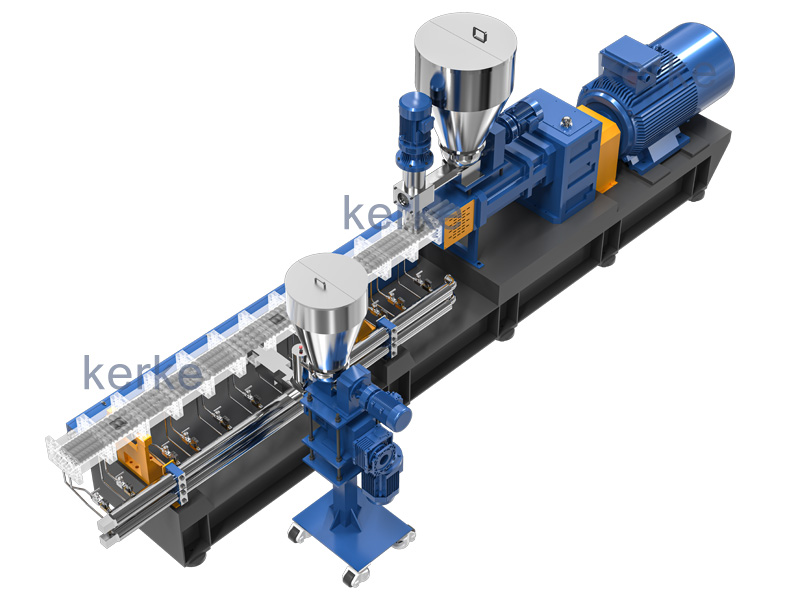

Parallel Twin Screw Extruder

Our Parallel Co-rotating twin screw extruder is designed for compounding and masterbatch making with an output capacity from…

-

Triple (3 screws) Extruder

3 Screws extruder is a new technology that has many advantages. The triple screw extruder is mainly used…

-

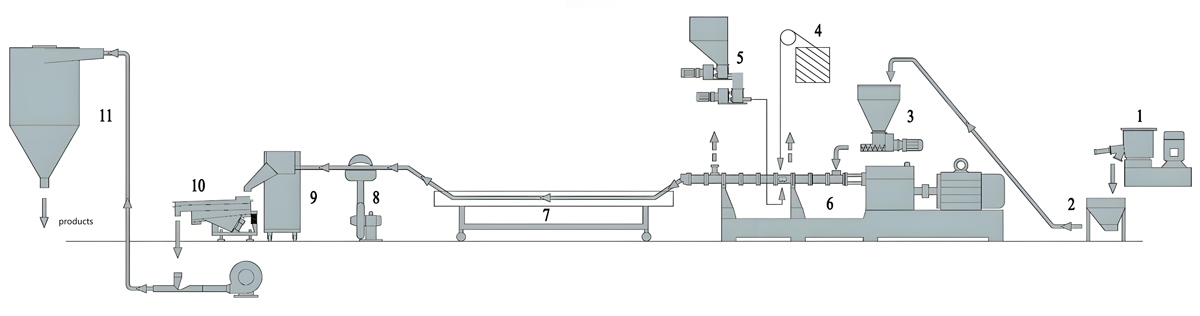

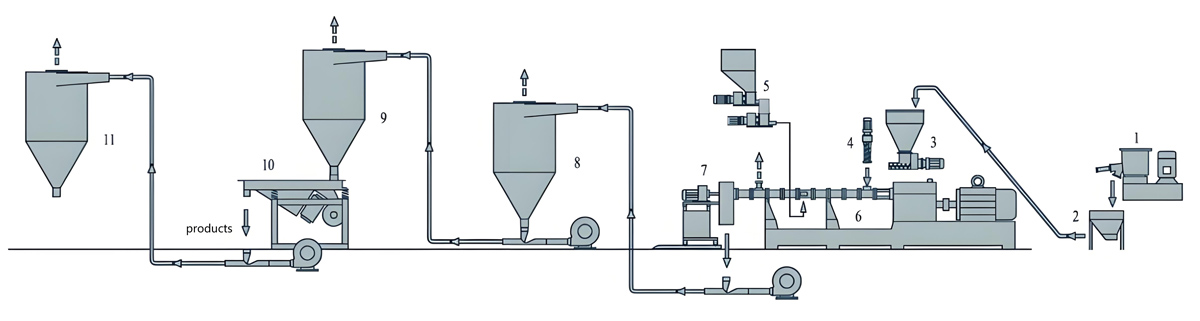

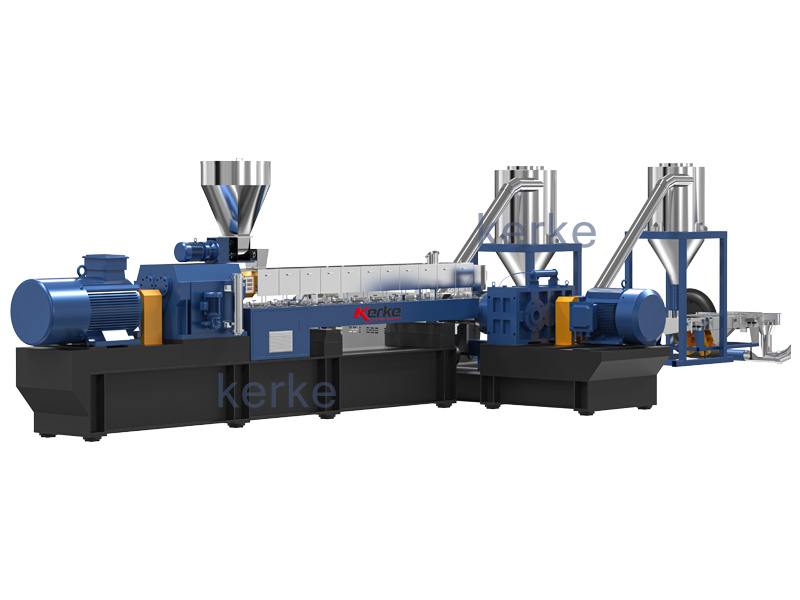

Double-Stage Extrusion System

Mother-baby extrusion system is designed for special materials which can not process on one stage extruder, the first…

-

Banbury Kneader Compounding Line

Our kneader + extruder is designed for making special applications with an output capacity from 30kg/h to 1000kg/h.…

-

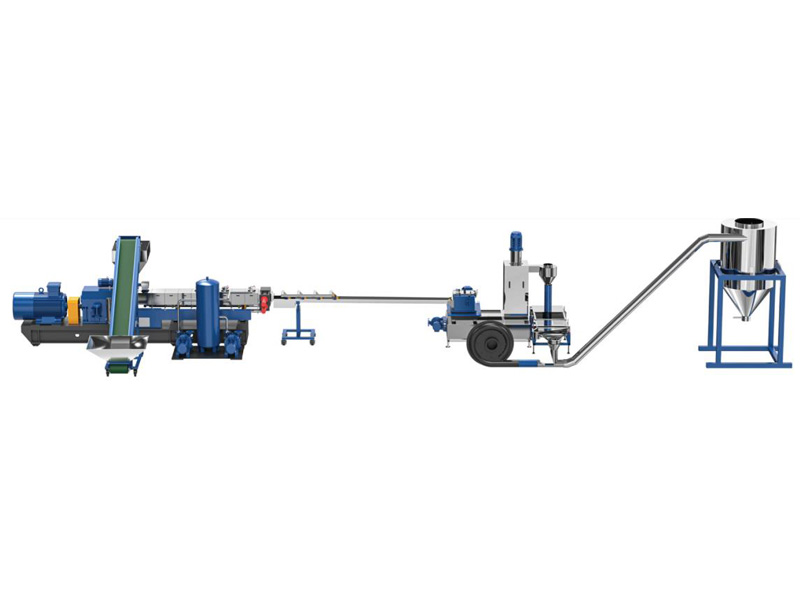

Cutting System / Pelletizing System

Different material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of…

Production process

The production of polyethylene modified masterbatch is a relatively complex process, usually including multiple steps such as raw material preparation, mixing, extrusion, granulation, etc. The following is its detailed production process:

1. Raw material preparation

Basic resin: Polyethylene (PE) resin is generally used as the basic raw material. Depending on the product performance requirements, different types of polyethylene such as low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE) can be selected. For example, LDPE has good flexibility and transparency, making it suitable for producing modified masterbatch with high requirements for softness and transparency; HDPE has high strength and rigidity, making it suitable for applications that require high mechanical properties.

Modifier: Various modifiers are added according to different modification purposes. Common modifiers include toughening agents, reinforcing agents, flame retardants, antistatic agents, lubricants, color masterbatch, etc. For example, in order to improve the toughness of polyethylene, elastic toughening agents can be added; To endow polyethylene with flame retardant properties, halogenated or halogen-free flame retardants can be added.

Other additives: Additional additives such as antioxidants and light stabilizers may also be added to improve the stability and weather resistance of modified masterbatch, preventing aging and degradation during processing and use.

2. Mixing

Add the prepared base resin, modifier, and other additives to the high-speed mixer according to a certain formula ratio for mixing. During the mixing process, the high-speed rotating stirring blades ensure that the materials are fully dispersed and evenly mixed. The usual mixing time is 5-15 minutes, depending on the characteristics of the material and the mixing effect. To ensure uniform mixing, batch addition or multiple mixing can be used.

3. Extrusion

Twin screw extruder: The mixed material is fed into the twin screw extruder for melt extrusion. The twin-screw extruder has good conveying capacity, shear mixing capacity, and dispersion capacity, which can fully plasticize and mix materials in the barrel. The temperature setting of an extruder is usually divided into multiple sections, from the hopper end to the head direction, with the temperature gradually increasing. Generally, the temperature of the front section of the barrel is between 160-180 ℃, the temperature of the middle section is between 180-200 ℃, and the temperature of the head is between 200-220 ℃. The screw speed is generally between 100-300 revolutions per minute and can be adjusted according to the fluidity of the material and product quality requirements.

Filtration: During the extrusion process, a melt filter is usually installed at the head of the extruder to remove impurities and undissolved particles from the material. The filtering accuracy can be selected according to product requirements, generally between 20-100 mesh.

4. Granulation

Air cooled pellet cutting: The molten material extruded by the extruder is extruded into strips through the die, and then enters the air cooled pellet cutting machine. In the air-cooled granulator, the high-speed rotating cutter cuts the strip into particles, while the particles are cooled by the air-cooled system to quickly solidify and shape. Air cooled pellet cutting is suitable for producing modified masterbatch with high requirements for particle appearance and small particle size.

Water cooled granulation: For some occasions that require high production efficiency, water cooled granulation technology can be used. The molten material is extruded from the die and directly enters the water tank for cooling, and then cut into particles by a granulator. The particles after water-cooled granulation need to undergo dehydration treatment, such as using a centrifugal dehydrator or a vibrating fluidized bed dryer to remove surface moisture.

5. Packaging

The modified masterbatch after granulation undergoes quality testing, and products that meet the requirements are packaged using an automatic packaging machine. The packaging specifications can be selected according to customer needs, generally including 25kg/bag, 50kg/bag, etc. The packaged products are stored in the warehouse, waiting for transportation and sale.

In the production process, it is necessary to strictly control the process parameters of each link to ensure the stability and consistency of product quality. At the same time, according to different product requirements and application fields, the formula and production process are continuously optimized to develop polyethylene modified masterbatch products with high performance and special functions.

Production equipment requirements

The production equipment for polyethylene modified masterbatch needs to meet the requirements of uniform mixing, good plasticization, and precise control. The following are specific equipment requirements:

Mixing equipment

High speed mixer: It should have high-strength mixing capacity and be able to mix polyethylene resin, modifiers, additives and other materials thoroughly and uniformly in a short period of time. The material of the mixer needs to be wear-resistant and corrosion-resistant stainless steel to adapt to the characteristics of various materials, ensure mixing quality and equipment life.

Ingredient system: High precision measuring devices such as electronic scales are required to accurately control the amount of various raw materials added, ensuring the accuracy of the formula and ensuring the stability of product quality.

Extrusion equipment

Twin screw extruder: This is one of the core equipment, requiring the screw to have good self-cleaning and conveying capabilities, and be able to adapt to materials of different viscosities. The aspect ratio is generally between 30-40 to provide sufficient residence time and shear force to fully plasticize and mix the material. The barrel is usually made of nitride steel or bimetallic alloy steel, which has good wear resistance and corrosion resistance.

Heating and cooling system: The heating method of the extruder is often electric heating or thermal oil heating, and the heating power should meet the plasticization requirements of the material in different temperature ranges, and the temperature control accuracy should be within ± 1 ℃. The cooling system generally adopts circulating water cooling, which can quickly and effectively control the temperature of the barrel and screw, preventing material overheating and decomposition.

Feeding device: High precision weight loss feeder or volumetric feeder is used, which can accurately and uniformly feed the mixed materials into the extruder barrel according to the screw speed and production requirements of the extruder, ensuring the stability of material supply.

Granulation equipment

Granulator: The cutting blade of the air-cooled granulator should be made of high-quality hard alloy or high-speed steel material, with sharp edges and good wear resistance, capable of cutting the extruded strip into uniform particles. In addition to the requirements for the cutting blade, the water-cooled granulator also needs to be equipped with an efficient dehydration device, such as a centrifugal dehydrator or a vibrating fluidized bed dryer, to ensure that the moisture on the surface of the particles can be quickly removed.

Cooling system: For air-cooled pellet cutting, an air-cooled system with sufficient air volume and speed is required to cool and solidify the pellets in a short period of time. Generally, forced air cooling is used, equipped with multiple fans for multi angle blowing. The cooling water tank for water-cooled pellet cutting should ensure stable water temperature and uniform water flow to ensure consistent cooling effect of the pellets.

Test equipment

Melt flow rate meter: used to detect the melt flow rate of polyethylene modified masterbatch to evaluate its processing performance, requiring high measurement accuracy and good repeatability.

Mechanical performance testing equipment: including tensile testing machines, impact testing machines, etc., used to test the mechanical properties such as tensile strength, elongation at break, and impact strength of products made from masterbatch. The equipment should have accurate loading and measurement systems.

Particle size analyzer: used to analyze the particle size distribution of particles to ensure that the particle size of the product meets the requirements. Advanced equipment such as laser particle size analyzer can be used, with a wide measurement range and high accuracy.

Other Auxiliary Equipment

Drying equipment: used for pre drying raw materials, removing moisture and volatile substances, and preventing problems such as bubbles or degradation during extrusion. Common drying equipment includes hot air circulation drying oven, dehumidification dryer, etc. The drying temperature and time can be adjusted according to the characteristics of the raw materials.

Packaging equipment: Automatic packaging machines are used to automate packaging processes such as measurement, filling, and sealing, improving packaging efficiency and quality. The measuring accuracy of the packaging machine should be high, and the sealing should be firm to ensure the sealing of the product during storage and transportation.

Formula ratio

The ratio of polyethylene modified masterbatch may vary due to factors such as modification purpose, performance requirements, and raw material characteristics. The following are some common examples of ratios:

High surface tension polyethylene filling masterbatch: modified polyethylene resin 8% -10%, ultrafine heavy calcium 85% -88%, surfactant 0.5% -1.5%, coupling agent 1% -2%, compatibilizer 0.8% -1.0%.

High density polyethylene toughening modified masterbatch: carrier (such as high-density polyethylene) 10% -30%, talc powder 50% -70%, compatibilizer (such as maleic anhydride grafted polyethylene) 10% -25%, coupling agent 1% -3%, dispersant 0.5% -2%, antioxidant 0.1% -1%.

Polyethylene modified asphalt masterbatch: 50-85 parts of polymer (polyethylene or its mixture with polyolefin elastomer), 10-35 parts of asphalt, 0.5-3.0 parts of graft modifier, 0.1-1.0 parts of chemical initiator, 1.0-3.0 parts of crosslinking agent, 1.0-4.0 parts of compatibilizer, 0.1-8.0 parts of additives (light stabilizer, antioxidant, anti stripping agent, etc.).

Blown film black masterbatch: Polyethylene resin 80% -90%, carbon black 5% -15%, antioxidant 0.5% -1%, plasticizer 1% -2%, dispersant 0.5% -1%.

Anti aging polyethylene modified master batch

Proportion: 80-90 parts of polyethylene resin (such as low-density polyethylene LDPE or linear low-density polyethylene LLDPE), 2-5 parts of light stabilizer (such as hindered amine light stabilizer HALS), 1-3 parts of antioxidant (such as hindered phenolic antioxidant), 2-5 parts of ultraviolet absorber (such as benzotriazole), and 0.5-1 part of dispersant (such as zinc stearate).

Description: Light stabilizers, antioxidants and ultraviolet absorbers work together to improve the anti-aging performance of polyethylene. Dispersants help these additives disperse evenly in polyethylene resin.

Highly transparent polyethylene modified masterbatch

Proportion: 85-95 parts of transparent polyethylene resin (such as metallocene polyethylene mPE), 0.5-2 parts of nucleating agent (such as dibenzylidene sorbitol DBS), 0.5-1 part of lubricant (such as ethylene bis (stearamide) EBS), 1-3 parts of plasticizer (such as dioctyl phthalate DOP, added as needed).

Explanation: Nucleating agents can refine the crystalline structure of polyethylene and improve transparency; Lubricants improve processing performance and prevent adhesion; Plasticizers can be added in appropriate amounts according to the requirements for softness and transparency to adjust the performance of the product.

Antibacterial polyethylene modified masterbatch

Proportion: 80-90 parts of polyethylene resin (such as high-density polyethylene HDPE), 2-5 parts of antibacterial agent (such as silver ion antibacterial agent or organic antibacterial agent), 1-3 parts of dispersant (such as silicone masterbatch), and 2-5 parts of compatibilizer (such as maleic anhydride grafted polyethylene).

Explanation: Antibacterial agents endow polyethylene with antibacterial function, dispersants evenly disperse antibacterial agents in the polyethylene matrix, compatibilizers improve the compatibility between antibacterial agents and polyethylene resin, ensuring the stability and long-term effectiveness of antibacterial performance.

Antistatic polyethylene modified masterbatch

Proportion: 70-80 parts of polyethylene resin (such as LDPE), 10-20 parts of antistatic agent (such as quaternary ammonium salt or polyether antistatic agent), 5-10 parts of carrier resin (such as EVA, ethylene vinyl acetate copolymer), 0.5-1 part of dispersant (such as stearic acid).

Explanation: Antistatic agent is a key component that reduces the surface resistance of polyethylene and prevents the accumulation of static electricity; The carrier resin helps to better disperse and exert anti-static agents in polyethylene, and the dispersant further improves the dispersion effect.

Flame retardant polyethylene modified masterbatch

Proportion: 60-75 parts of polyethylene resin (such as HDPE or LLDPE), 20-30 parts of flame retardant (such as inorganic flame retardants such as aluminum hydroxide and magnesium hydroxide, or organic flame retardants such as bromine and phosphorus), 2-5 parts of synergist (such as antimony trioxide, used in combination with bromine flame retardants), 1-2 parts of lubricant (such as paraffin), and 0.5-1 part of antioxidant.

Explanation: Flame retardants are the key to achieving flame retardancy, and synergists work together with flame retardants to improve flame retardancy; Lubricants improve processing performance, while antioxidants prevent polyethylene from being affected by thermal oxidation during processing and use.

These ratios are for reference only, and in actual production, they need to be optimized and adjusted based on specific modification requirements, raw material characteristics, processing technology, and cost factors. At the same time, strict performance testing and quality control are required to ensure that the modified masterbatch achieves the expected performance indicators.

Applications

Polyethylene modified masterbatch endows polyethylene with new properties and characteristics by adding various modifiers to polyethylene resin, and is widely used in various fields such as packaging, agriculture, construction, healthcare, and automobiles. The following is a specific introduction:

Packaging field

Improving film performance: Adding anti puncture modified masterbatch in plastic film production can enhance the anti puncture strength of polyethylene film, making it less likely to be punctured when packaging sharp objects and protecting the contents. Adding smooth modified masterbatch can reduce the friction coefficient of the film surface, making it easier to unfold and operate during processing and use, while also preventing adhesion between films.

Improving barrier performance: By adding barrier modified masterbatch, such as masterbatch containing nanoclay or silicon oxide, the barrier performance of polyethylene film against oxygen, water vapor, etc. can be improved, extending the shelf life of packaged food, drugs, etc.

agriculture

Production of multifunctional agricultural film: Adding anti-aging modified masterbatch can improve the weather resistance of polyethylene agricultural film, making it less prone to aging and cracking during long-term outdoor use, and extending the service life of agricultural film. Adding insulation modified masterbatch can make agricultural film have good insulation performance, which helps maintain the temperature environment required for crop growth.

Manufacturing drip irrigation tape: In the production of polyethylene drip irrigation tape, adding anti clogging modified masterbatch can make the inner wall of the drip irrigation tape smoother, reduce the adhesion of impurities and minerals in the water, prevent droplet head clogging, and ensure the stable operation of the drip irrigation system.

Construction field

Enhancing pipe performance: Adding reinforced modified masterbatch, such as glass fiber reinforced masterbatch, to polyethylene pipes can improve their strength and rigidity, enabling them to withstand greater pressure and external forces, making them suitable for fields such as building water supply and drainage, and gas transportation. Adding heat-resistant modified masterbatch can improve the heat resistance of polyethylene pipes, enabling them to be used stably at higher temperatures.

For waterproofing membranes: Adding modified masterbatch with high elasticity and weather resistance to polyethylene waterproofing membranes can improve their flexibility, tear resistance, and aging resistance, making them better suited for waterproofing requirements in different parts of buildings such as roofs and underground engineering.

Medical field

Manufacturing medical packaging materials: Adding antibacterial modified masterbatch to polyethylene medical packaging materials can give the packaging materials antibacterial function, effectively inhibit bacterial growth, and protect medical devices and drugs from microbial contamination. Adding transparent modified masterbatch can improve the transparency of polyethylene packaging materials, making it easier to observe the contents.

Production of medical tubing: When producing medical polyethylene tubing, adding biocompatible modified masterbatch can make the tubing have good compatibility with human tissues, reduce irritation and adverse reactions to the human body, and is suitable for manufacturing medical tubing such as urinary catheters and infusion tubes.

Automotive field

Interior application: Adding anti-static modified masterbatch to polyethylene automotive interior can effectively eliminate static electricity on the interior surface, prevent dust adsorption, and improve the cleanliness and aesthetics of the interior. Adding soft modified masterbatch can provide better hand feel and comfort to polyethylene interior parts.

Application of exterior parts: Adding weather resistant and chemical corrosion resistant modified masterbatch to polyethylene automotive exterior parts can improve their aging resistance and chemical corrosion resistance in outdoor environments, maintaining their good appearance and performance.