Polyethylene masterbatch is widely used in the production of various plastic products, such as plastic bags, plastic films, plastic pipes, etc. By adding different additives and fillers, polyethylene products with different properties and uses can be produced. The production of polyethylene masterbatch is a complex and delicate process that requires strict control over raw material quality, equipment selection, process parameters, and safety production. By continuously optimizing production processes and formulas, the quality and performance of masterbatch can be improved to meet market demand.

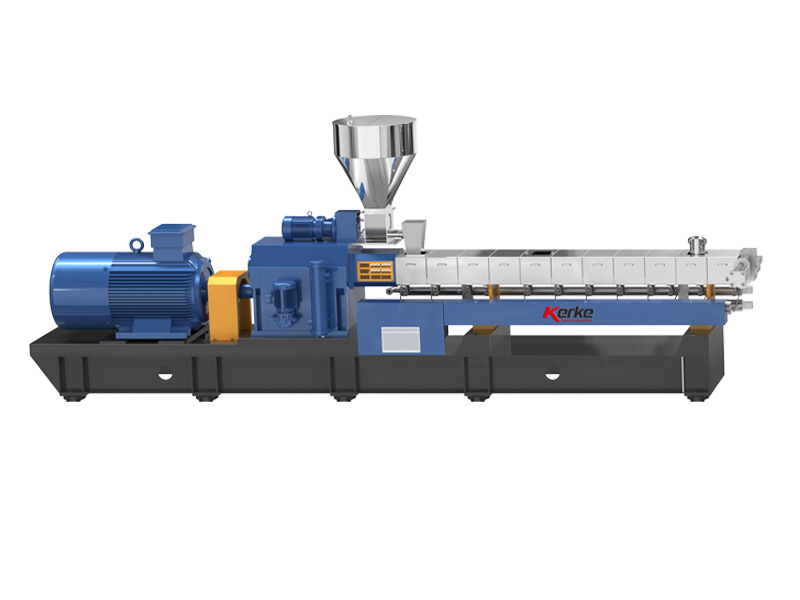

Polyethylene masterbatch extruder

Kerke’s masterbatch extruder can be used to produce polyethylene masterbatch. Our masterbatch extruder has multiple models to choose from, which can meet different production requirements.

-

Laboratory Twin Screw Extruder

When will you need a lab twin screw extruder? If you want to make trials and tests of…

-

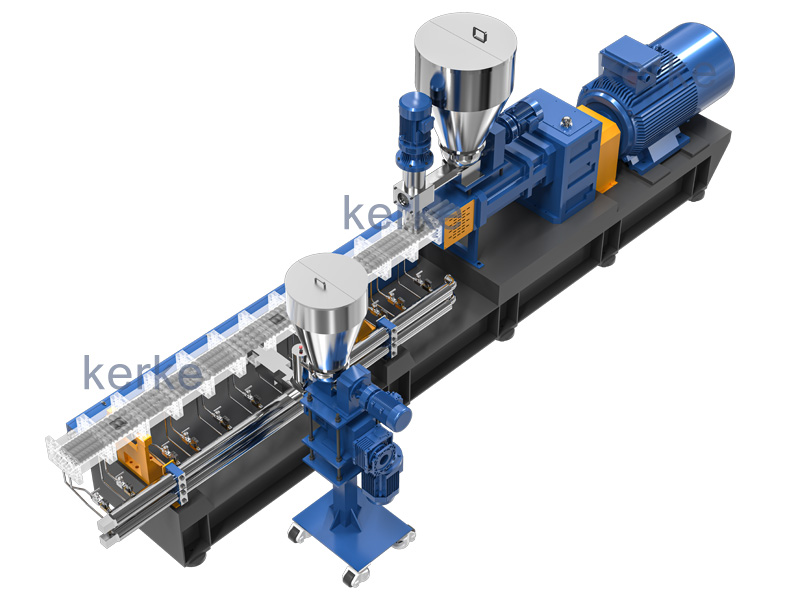

Parallel Twin Screw Extruder

Our Parallel Co-rotating twin screw extruder is designed for compounding and masterbatch making with an output capacity from…

-

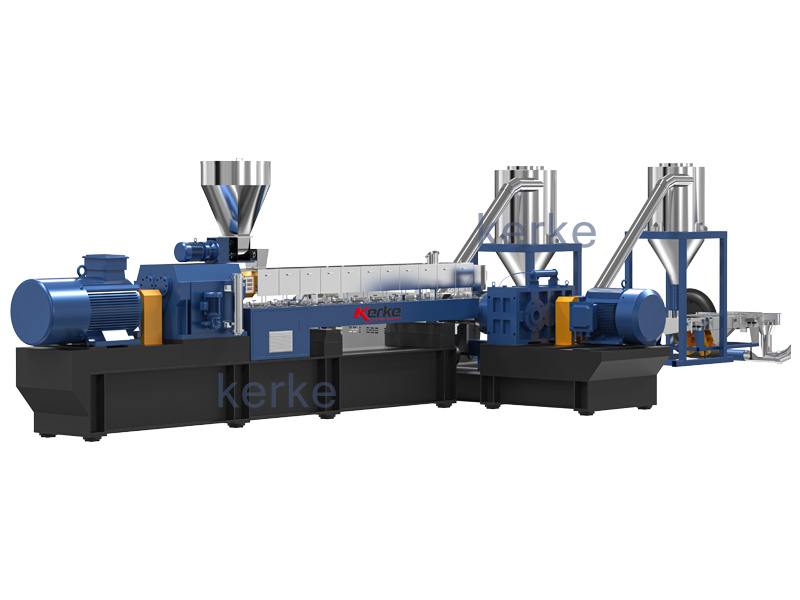

Triple (3 screws) Extruder

3 Screws extruder is a new technology that has many advantages. The triple screw extruder is mainly used…

-

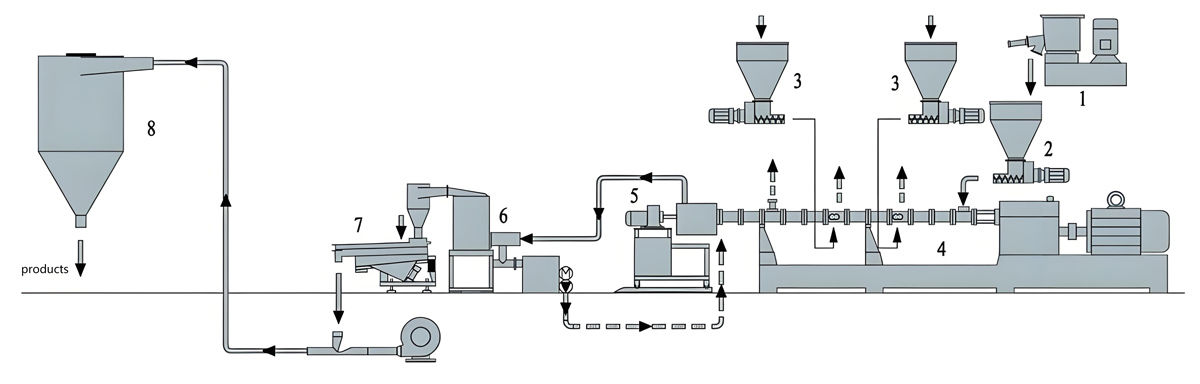

Double-Stage Extrusion System

Mother-baby extrusion system is designed for special materials which can not process on one stage extruder, the first…

-

Banbury Kneader Compounding Line

Our kneader + extruder is designed for making special applications with an output capacity from 30kg/h to 1000kg/h.…

-

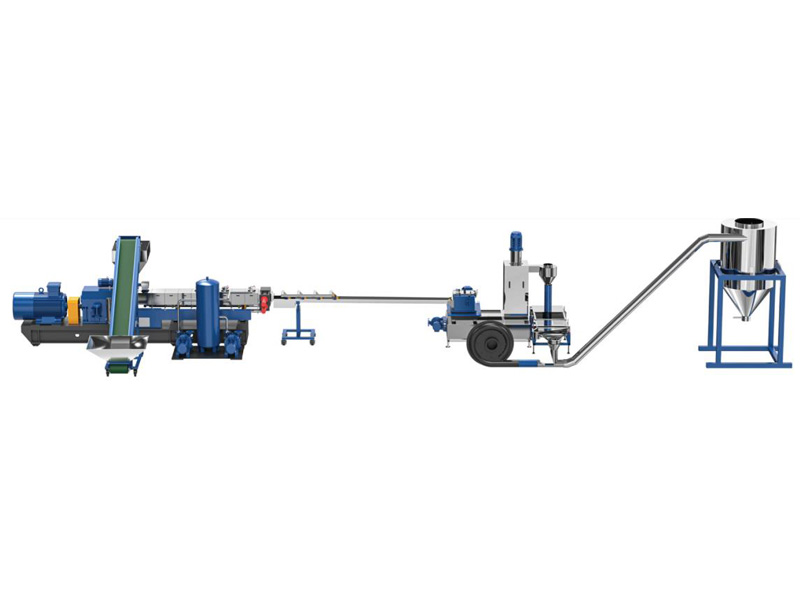

Cutting System / Pelletizing System

Different material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of…

Production process

Raw material preparation

Basic resin: Polyethylene resin is generally selected, such as low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), or high-density polyethylene (HDPE), etc. The appropriate variety and grade are selected according to the product performance requirements.

Additives: Various additives are added according to the functional requirements of the masterbatch, such as pigments or dyes that need to be added to the color masterbatch; Filling masterbatch requires the addition of fillers such as calcium carbonate and talc powder; Functional masterbatch is added with antioxidants, light stabilizers, flame retardants, etc.

Mixing of ingredients

Measurement: Accurately measure the amount of various raw materials and additives according to the formula requirements. Accurate measuring equipment such as electronic scales are usually used to ensure the accuracy of ingredients.

Pre mixing: Pour the measured raw materials and additives into a high-speed mixer for pre mixing. By high-speed stirring, various components are initially uniformly dispersed. The general mixing time is 5-15 minutes, depending on the characteristics of the material and the mixing effect.

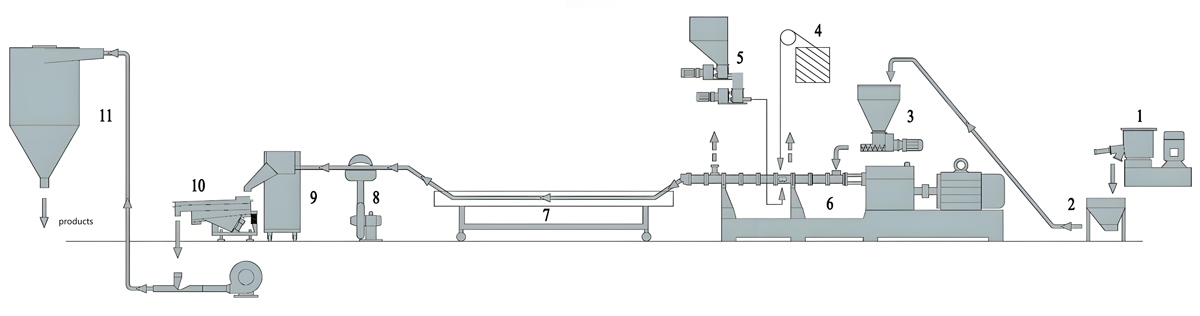

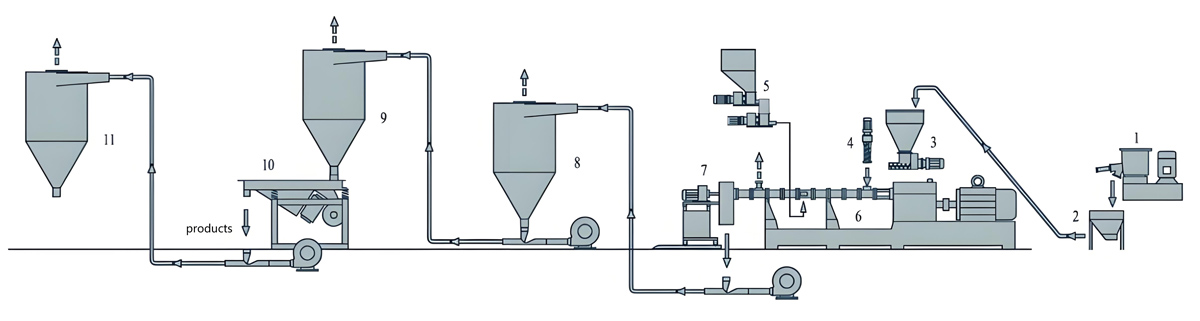

Extrusion granulation

Melt extrusion: Add pre mixed materials into a twin-screw extruder. The extruder gradually heats the material inside the barrel to the melting temperature of polyethylene through heating and rotation of the screw, usually between 160-230 ℃. In the molten state, the material is subjected to the shearing and conveying effects of the screw, further mixing evenly.

Filtering: In order to remove impurities and undispersed particles from the material, filtering devices such as filters or melt filters are usually installed during the extrusion process. The filtration accuracy depends on the product requirements and is generally between 20-100 mesh.

Granulation: The filtered molten material is extruded from the die of the extruder to form continuous strips or filaments. Then it is cut into granules of a certain length by a granulator. Common granulation methods include air-cooled granulation, water-cooled granulation, and underwater granulation. Air cooled pellet cutting is suitable for occasions with high requirements for particle appearance; Water cooling has a high cutting efficiency, but there may be residual moisture on the surface of the particles; Underwater particle cutting has the advantages of regular particle shape and uniform size, but the equipment cost is relatively high.

Packaging and storage

Cooling screening: The polyethylene masterbatch particles after granulation need to be cooled to around room temperature. Then, the particles are sieved through equipment such as vibrating screens to remove particles that are too large or too small, ensuring the uniformity of the product’s particle size.

Packaging: The screened masterbatch particles are packaged according to a certain weight specification, usually using plastic woven bags or paper bags to prevent the product from getting damp or contaminated. The packaged products are stored in a dry and ventilated warehouse, waiting for factory sales.

In the production process, it is necessary to strictly control the process parameters of each link, such as temperature, pressure, screw speed, feeding speed, etc., to ensure the stability and consistency of product quality. At the same time, it is necessary to strengthen the quality inspection of raw materials and products, including the inspection of appearance, particle size, melt flow rate, density, additive content and other indicators, in order to timely discover and solve problems.

Production equipment requirements

The production equipment for polyethylene masterbatch needs to meet the requirements of high-precision measurement, uniform mixing, sufficient plasticization, precise filtration, and stable granulation. The following are specific instructions:

1. Ingredient equipment

High precision electronic scale: It is required to accurately measure various raw materials and additives, with an accuracy usually reaching ± 0.1% or higher, to ensure the accuracy of the formula.

High speed mixer: It has good mixing effect and can evenly mix materials in a short time. The speed of the mixer can be adjusted, generally between 500-2000 revolutions per minute, and it has heating and cooling functions to meet the mixing needs of different materials.

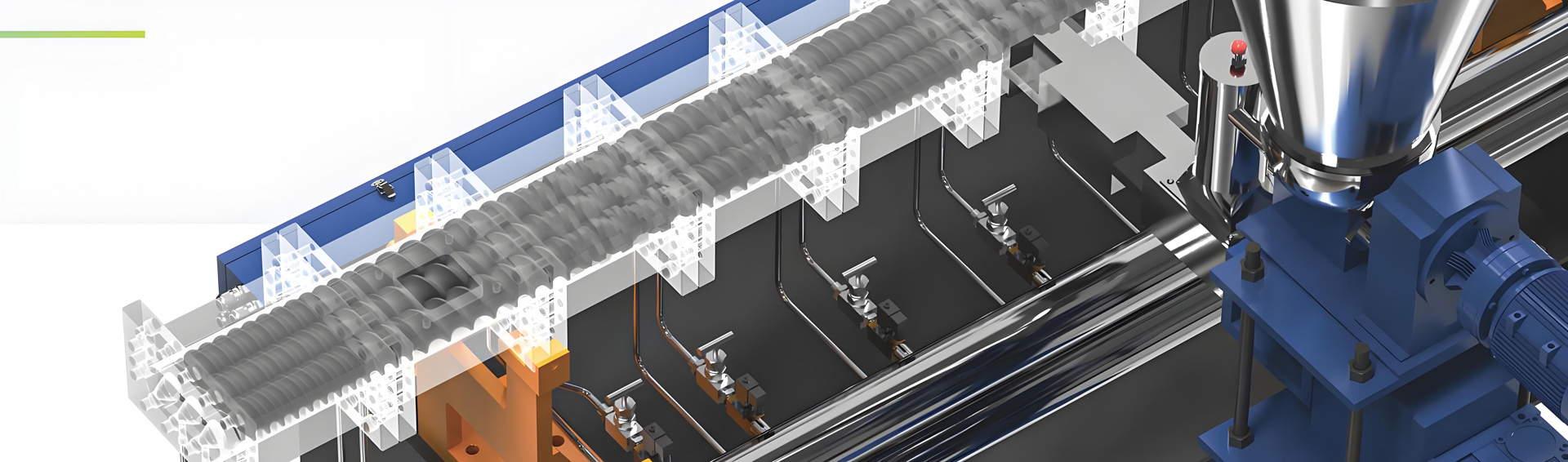

2. Extrusion equipment

Twin screw extruder: The aspect ratio is generally between 25-40 to ensure sufficient residence time and plasticization and mixing effect of the material in the barrel. The structural design of the screw should be reasonable, with strong conveying and shear mixing capabilities, and able to adapt to materials of different viscosities. The heating system of the extruder should be precise and controllable, with temperature control accuracy within ± 2 ℃, to ensure that the material is melted and extruded at the appropriate temperature.

Single screw extruder: For the production of polyethylene masterbatch with low shear requirements and high output, single screw extruders are also used. The diameter of its screw is usually between 45-150 millimeters, and the aspect ratio is between 20-30. The advantages of single screw extruder are simple structure and low cost, but the mixing effect is slightly worse than that of twin-screw extruder. Generally, optimization is needed in the screw structure and head design to improve the mixing uniformity of materials.

3. Filtering equipment

Melt filter: installed near the head of the extruder, used to filter impurities and undissolved particles in the molten material. The filtration accuracy can be selected between 20-100 mesh according to product requirements, usually using an automatic backwash filter that can clean and replace the filter screen without stopping, ensuring the continuity of production.

4. Granulation equipment

Air cooled granulator: suitable for producing polyethylene masterbatch with high requirements for particle appearance. The material of the cutting tool should be wear-resistant, and the cutting speed can be adjusted, usually 100-500 revolutions per minute, to ensure that the shape of the particles is regular and the size is uniform. The air cooling system should be able to effectively cool the particles to room temperature and avoid particle adhesion.

Water cooled pellet cutter: It has high production efficiency, and the pellets are cooled in water with fast cooling speed. But dehydration equipment such as centrifugal dehydrators or vibrating fluidized bed dryers are required to remove moisture from the surface of particles.

Underwater granulator: It is a relatively advanced granulation equipment that cuts and cools particles underwater, with the advantages of regular particle shape, high dimensional accuracy, and no dust. But the equipment cost is relatively high, and there are also strict requirements for operation and maintenance.

5. Packaging equipment

Automatic packaging machine: capable of automatically measuring and packaging according to the set weight, with a packaging speed of generally 5-10 bags/minute and a packaging accuracy of ± 0.5%. The packaging machine can be equipped with different packaging forms, such as three side sealing, four side sealing, etc., to meet the needs of different customers.

Stacking machine: For large-scale production enterprises, palletizing machines can be used to automatically stack packaged products, improving production efficiency and the standardization of warehouse management. The stacking speed and carrying capacity of the palletizer should be selected according to the production scale and product packaging weight.

6. Auxiliary equipment

Feeding system: including automatic feeding machines, hoppers, etc., which can automatically transport raw materials and additives to batching equipment and extruders, achieving automated production and reducing manual operation errors. The conveying capacity of the feeding system should match the output of the production equipment.

Cooling system: provides cooling circulating water for extruders, granulators and other equipment to ensure that the equipment operates at normal temperature. The cooling capacity of the cooling system should be calculated and selected based on the heat generation of the equipment, usually using a chiller or cooling tower as the cooling source.

Electrical control system: Centralized control and monitoring of the entire production equipment, realizing the setting, adjustment, and display of process parameters, as well as the functions of equipment start stop, fault alarm, etc. The electrical control system requires high stability and reliability, and can adapt to industrial production environments.

Applications

Polyethylene masterbatch is a polymer material based on polyethylene, with various functional additives or fillers added. It has a wide range of applications in the field of plastic processing. The following are some of the main application aspects:

BOPP

Agricultural film: a polyethylene film with added anti-aging, anti fog, insulation and other functional mother materials, which can be used for greenhouse covering, crop cultivation, etc. in agricultural production. Anti aging masterbatch can improve the weather resistance of the film and extend its service life; The anti fog droplet masterbatch reduces the formation of water droplets on the surface of the film, improves light transmittance and insulation effect, and is beneficial for the growth of crops.

Packaging film: Adding a smooth masterbatch to polyethylene packaging film can reduce the friction coefficient of the film surface, making it easier to roll and use the film; Adding anti-static masterbatch can prevent static electricity from forming on the surface of the film, avoid adsorbing dust and impurities, and improve packaging quality.

Pipe products

Water supply pipe: Polyethylene water supply pipes are added with environmentally stress cracking resistant masterbatch, which can improve the anti cracking performance of the pipes and ensure that they will not rupture due to environmental factors during long-term use. At the same time, adding color masterbatch can give the pipe different colors, making it easy to distinguish and identify.

Gas pipe: When producing polyethylene gas pipes, flame retardant masterbatch and UV resistant masterbatch need to be added. Flame retardant masterbatch can improve the flame retardant performance of pipes and enhance safety; UV resistant masterbatch can prevent pipes from aging due to long-term exposure to ultraviolet radiation outdoors, extending their service life.

injection molding products

Plastic containers: Adding toughening masterbatch to polyethylene injection molded plastic containers can improve their impact resistance and make them less prone to breakage during use; Adding filler masterbatch can reduce production costs while improving the rigidity and hardness of the container.

Turnover box: Polyethylene turnover boxes are often added with wear-resistant masterbatch to improve their surface wear resistance, reduce wear during frequent use and handling, and extend the service life of turnover boxes.

Fiber products

Polypropylene fiber: Adding polyethylene masterbatch in the production of polypropylene fiber can improve the dyeing performance, anti-static performance, and softness of the fiber. For example, adding dyeing masterbatch can make fibers easier to color, with bright and firm colors; Adding anti-static masterbatch can eliminate the static electricity generated by fibers during processing and use, improving processability and user comfort.

Non woven fabric: Polyethylene non-woven fabric contains anti sticking masterbatch, which can prevent fibers from sticking to each other during the production process, improve production efficiency and product quality; Adding hydrophilic masterbatch can make non-woven fabrics have good water absorption and breathability, suitable for fields such as hygiene products and medical supplies.