Polyethylene film masterbatch refers to additive particles uniformly dispersed in polymers, such as flame retardants, Caco3 powder, etc. These additives can endow polyethylene film with specific properties. Polyethylene film masterbatch has broad application prospects in the plastic products industry and is an important raw material for manufacturing polyethylene film, with various types and excellent properties. In terms of production technology, it is necessary to strictly control the proportion of raw materials and process parameters to ensure product quality.

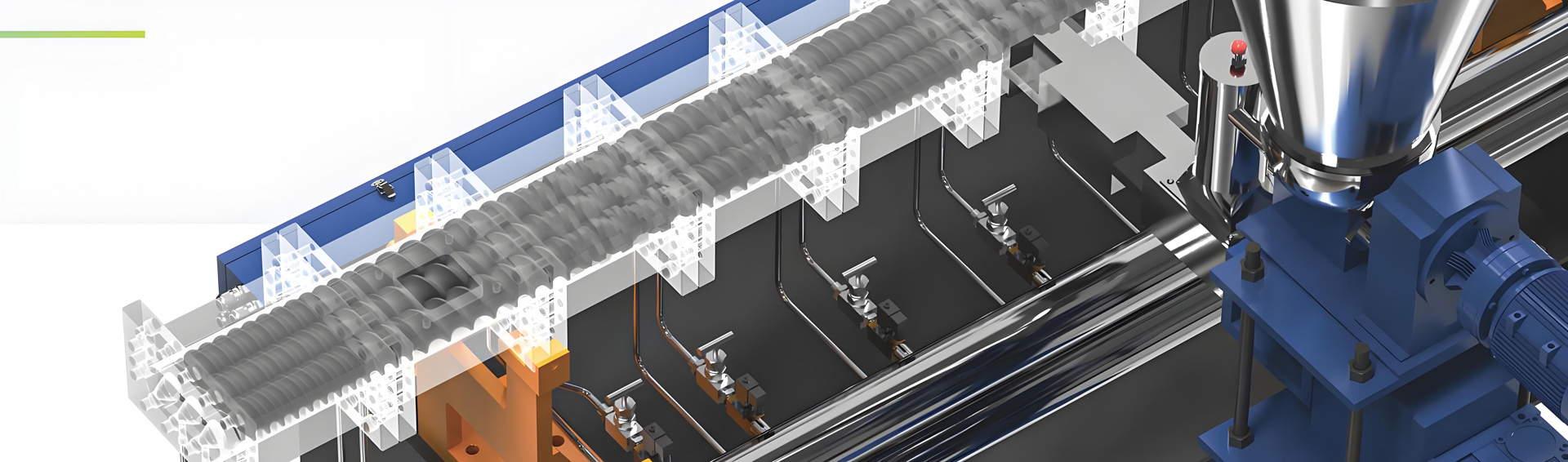

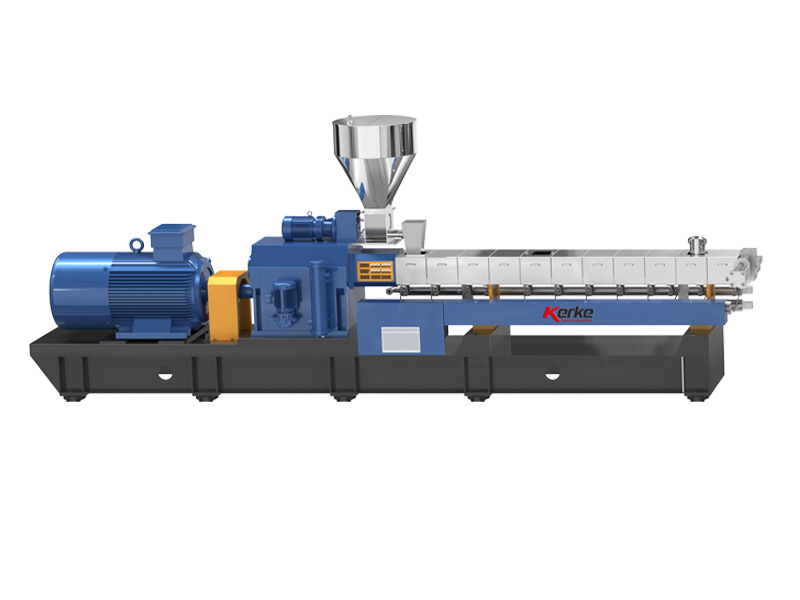

Polyethylene film masterbatch extruder

Kerke’s masterbatch extruder can be used to produce polyethylene film masterbatch. Our masterbatch extruder has multiple models to choose from, which can meet different production requirements.

-

Laboratory Twin Screw Extruder

When will you need a lab twin screw extruder? If you want to make trials and tests of…

-

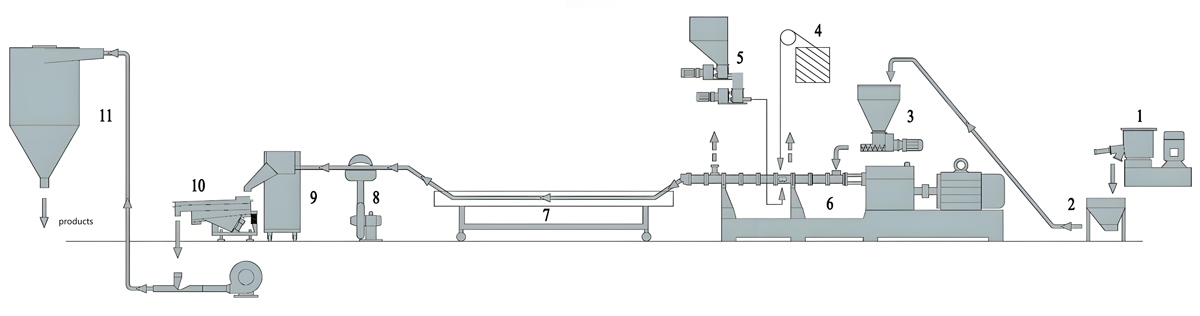

Parallel Twin Screw Extruder

Our Parallel Co-rotating twin screw extruder is designed for compounding and masterbatch making with an output capacity from…

-

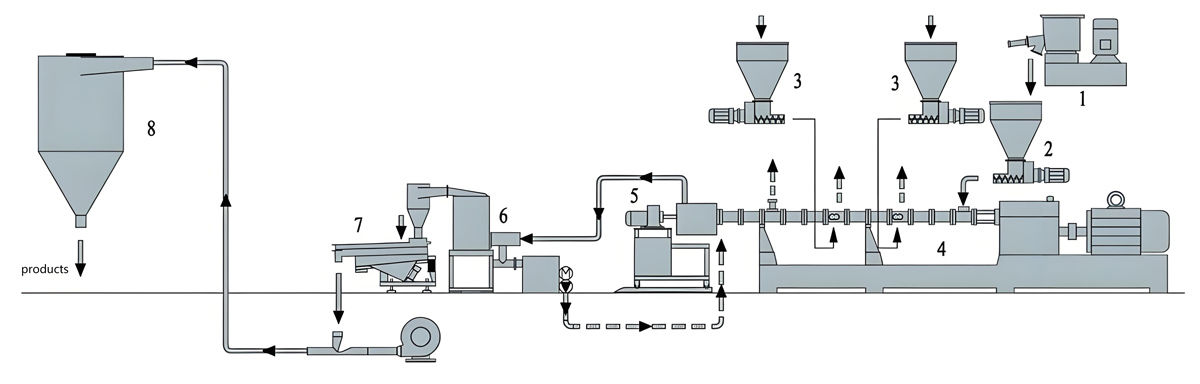

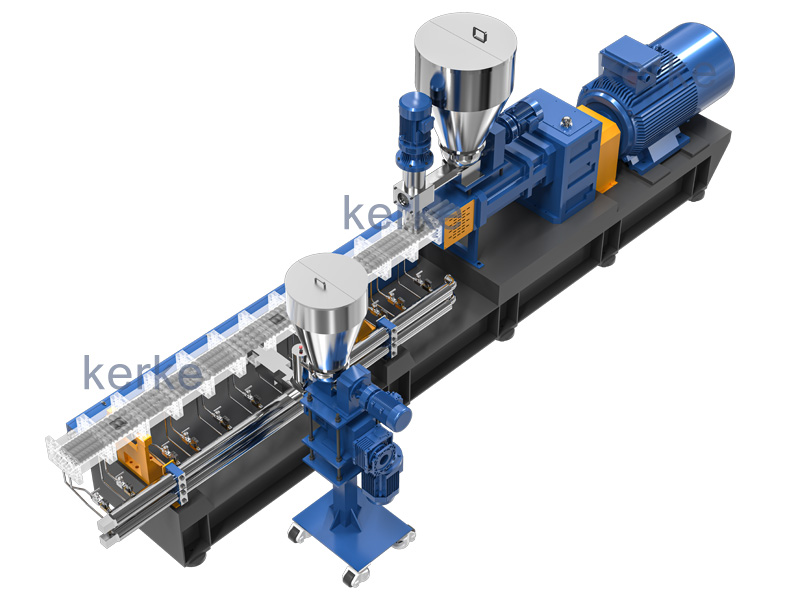

Triple (3 screws) Extruder

3 Screws extruder is a new technology that has many advantages. The triple screw extruder is mainly used…

-

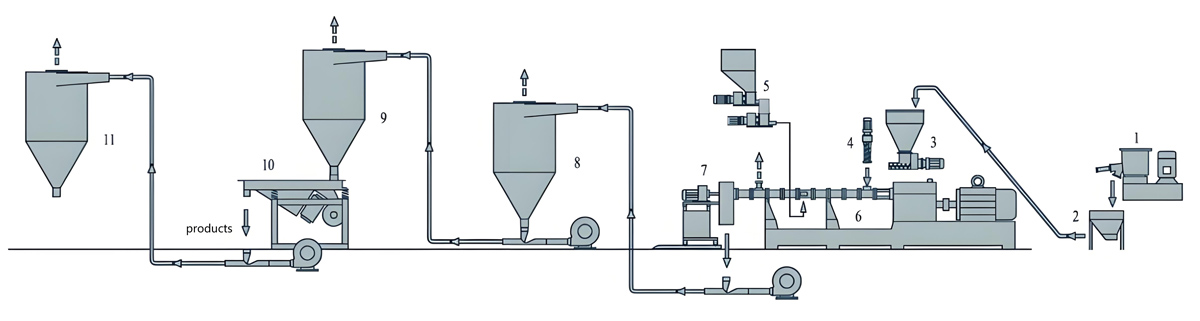

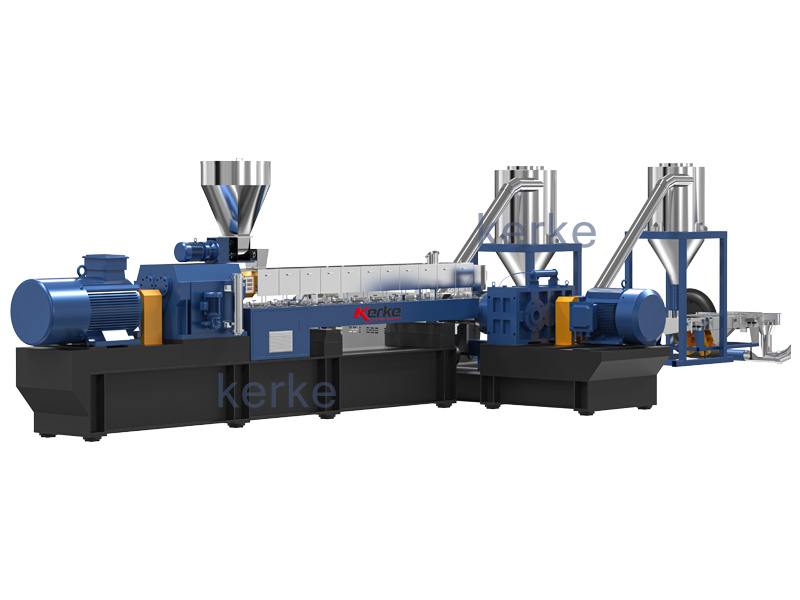

Double-Stage Extrusion System

Mother-baby extrusion system is designed for special materials which can not process on one stage extruder, the first…

-

Banbury Kneader Compounding Line

Our kneader + extruder is designed for making special applications with an output capacity from 30kg/h to 1000kg/h.…

-

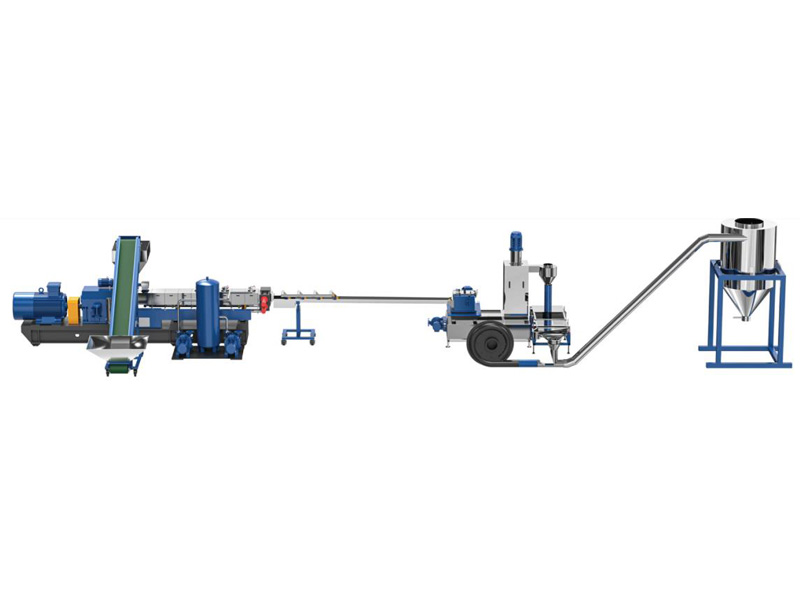

Cutting System / Pelletizing System

Different material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of…

Production process

The production process of polyethylene film masterbatch usually includes multiple steps such as raw material preparation, ingredient mixing, melt extrusion, granulation, cooling and drying, and packaging. The following is a specific introduction:

1. Raw material preparation

Basic resin: Select suitable polyethylene resin, such as low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), or high-density polyethylene (HDPE), etc., and determine the specific variety and grade based on the performance requirements of the film.

Additives: According to the functional requirements of the masterbatch, various additives are added, such as antioxidants, light stabilizers, lubricants, opening agents, color masterbatch, etc. These additives can improve the processing performance, physical properties, and service life of polyethylene film.

2. Mixing of ingredients

Accurately weigh the polyethylene resin and additives in a certain proportion, and then put them into a high-speed mixer for thorough mixing. By stirring, the additive is evenly dispersed in the polyethylene resin particles to ensure the uniformity of each component in the subsequent production process.

3. Melt extrusion

The mixed materials enter the hopper of the extruder and are pushed forward by the rotation of the screw. During this process, the material is gradually heated to a molten state.

The temperature setting of the extruder is crucial and needs to be adjusted reasonably according to the type and characteristics of polyethylene resin and the requirements of additives. Generally speaking, the temperature gradually increases from the hopper to the machine head to ensure that the material can be fully melted and has good fluidity.

During the melting process, the shear action of the screw further mixes the additive and polyethylene resin evenly, while also plasticizing the material to achieve a suitable extrusion state.

4. Granulation

After the molten material is extruded from the extruder head, it is formed into small strips or granules through specific granulation molds. The common granulation methods include hot cutting granulation and cold cutting granulation.

Hot cutting granulation is the process of using a rotating tool to cut the material into granules while extruding it, resulting in a more regular shape and uniform size of the granules.

Cold cutting granulation is the process of first cooling and solidifying the extruded strip material, and then cutting it into granules using a granulator. This method is suitable for situations where particle shape and size requirements are not particularly strict.

5. Cooling and drying

The polyethylene film masterbatch after granulation needs to be cooled to reduce its temperature and solidify into shape. Usually, air or water cooling is used for cooling.

Air cooling is the process of forcing air flow to remove heat from the surface of particles, resulting in rapid cooling of the particles. Water cooling is the process of cooling particles through a water tank, with a fast cooling rate. However, it is important to control the amount and temperature of the cooling water to avoid surface defects on the particles.

The cooled masterbatch may contain some moisture and needs to be dried to remove moisture and prevent moisture, clumping, and other issues during storage and use. Drying methods can include hot air drying or vacuum drying.

6. Packaging

After cooling and drying, the polyethylene film masterbatch can be packaged once it meets the specified quality standards. Generally, plastic woven bags or paper bags are used for packaging, and the weight of each bag depends on market demand and customer requirements.

During the packaging process, attention should be paid to preventing the masterbatch from being contaminated and dampened. At the same time, the product name, specifications, production date, shelf life, and other relevant information should be marked on the packaging bag for storage, transportation, and use management.

Throughout the entire production process, it is necessary to strictly control the process parameters of each link to ensure the quality stability and performance compliance of polyethylene film masterbatch. At the same time, regular maintenance and upkeep of production equipment are necessary to ensure its normal operation, improve production efficiency and product quality.

Production machine

The production of polyethylene film masterbatch requires various equipment, mainly including the following categories:

Batching equipment

Electronic scale: used for precise weighing of various raw materials such as polyethylene resin and additives, ensuring accurate ingredient ratios and stable product quality.

High speed mixer: Mix the weighed raw materials thoroughly and evenly, so that the additives are evenly distributed in the polyethylene resin, laying the foundation for subsequent processing.

Extrusion granulation equipment

Single screw or twin-screw extruder: The material is pushed forward by the rotation of the screw, while heating, melting, and plasticizing the material to achieve a suitable extrusion state. Compared to single screw extruders, twin-screw extruders have better mixing performance and self-cleaning ability, making them more suitable for producing high-quality polyethylene film masterbatch.

Extrusion mold: Installed at the head of the extruder, it determines the shape and size of the extruded material. According to different granulation methods, there are molds used for hot cutting granulation and molds used for cold cutting granulation.

Granulator: In conjunction with an extruder, it cuts the extruded molten material into granules. The hot cutting granulator cuts directly during material extrusion, while the cold cutting granulator cools the extruded strip before cutting.

Cooling and drying equipment

Cooling water tank or air cooling system: used to cool the mother granules after granulation. The water cooling method has a fast cooling speed and can quickly shape the particles; The air cooling method takes away heat by forcing air flow, which is suitable for some moisture sensitive masterbatch.

Drying machine: Remove moisture from the surface or interior of the cooled masterbatch to prevent moisture and clumping. Common types include hot air dryer and vacuum dryer. Hot air dryer dries masterbatch through hot air circulation, while vacuum dryer dries in a vacuum environment, which can effectively reduce the drying temperature and is suitable for some temperature sensitive additives.

Auxiliary equipment

Feeding machine: Automatically transports raw materials from the storage area to the hopper of the batching or extrusion equipment, improving production automation, reducing manual labor intensity, and avoiding contamination of raw materials during transportation.

Screening machine: Screen the mother granules after granulation, remove particles that are too large or too small, as well as possible impurities, to ensure the uniformity and quality of the product’s particle size.

Packaging machine: Packaging qualified polyethylene film masterbatch that has been inspected. There are usually automatic packaging machines and semi-automatic packaging machines, which can be selected according to production scale and packaging requirements. The packaging machine can complete packaging processes such as measurement, filling, and sealing, ensuring that the product is not damaged during storage and transportation.

In addition, according to the needs of production processes and product quality control, some testing equipment may be equipped, such as melt flow rate meters, tensile testing machines, thermal analyzers, etc., to detect various performance indicators of masterbatch, in order to ensure that product quality meets standards and customer requirements.

Related requirements

In the production of polyethylene film masterbatch, the extruder needs to meet various requirements such as plasticization, mixing, temperature control, etc. to ensure product quality and production efficiency, as follows:

Efficient plasticization and mixing

Screw structure: Adopting a gradient screw with a length to diameter ratio generally between 25-32. A larger aspect ratio can provide a longer plasticization and mixing process, allowing polyethylene raw materials to be fully plasticized. At the same time, appropriate mixing elements should be installed on the screw, such as barrier type mixing sections or pin mixing sections, to enhance the shear and mixing effect of the material and ensure uniform mixing of additives and polyethylene resin.

Drive power: Depending on the output of the extruder, a corresponding power drive motor is required. Generally speaking, for extruders used in the production of polyethylene film masterbatch, with an hourly output of 100-500 kilograms, the driving power is usually between 30-110 kilowatts to ensure that the screw can provide sufficient torque and speed to achieve efficient plasticization and mixing.

Accurate temperature control

Heating method: Electric heating is commonly used, which has the advantages of fast heating speed and precise temperature control. The heating coil is evenly distributed on the barrel, and precise temperature adjustment is carried out through a temperature controller. In addition, some extruders use thermal oil heating, which can provide a more uniform temperature distribution and is suitable for occasions with high temperature control requirements.

Temperature control accuracy: During the production process of polyethylene film masterbatch, the temperature control accuracy needs to be within ± 1 ℃. Different production stages require strict temperature control. For example, in the plasticizing stage of raw materials, the temperature is generally controlled between 150-200 ℃; During the extrusion molding stage, the temperature is fine tuned according to the thickness and performance requirements of the film, usually within the range of 160-190 ℃.

Stable pressure control

Pressure stability: During the extrusion process, stable pressure is crucial for ensuring the dimensional accuracy and appearance quality of the film masterbatch. The hydraulic system or mechanical transmission system of the extruder should be able to provide stable pressure output, with pressure fluctuations generally controlled within ± 3%. Stable pressure can evenly extrude materials at the machine head, avoiding uneven thickness or uneven surface.

Pressure regulating device: equipped with flexible pressure regulating devices such as back pressure valves or throttle valves. Operators can adjust the back pressure of the screw and thus adjust the extrusion pressure by adjusting these devices according to production needs. For example, when producing thinner polyethylene film masterbatch, it is necessary to increase the extrusion pressure appropriately to ensure that the material can fully fill the mold and achieve good molding results.

Good material conveying

Feeding device: High precision feeding equipment, such as weight loss feeders, is used. It can accurately transport materials such as polyethylene resin and additives to the extruder according to the set formula ratio. The weight loss feeder continuously measures the weight change of the material in the hopper and automatically adjusts the feeding amount according to the preset feeding rate to ensure the precise addition of the material, thereby ensuring the stability of product quality.

Screw conveying capacity: The design of the screw should have good material conveying capacity, which can stably transport materials from the feeding port to the machine head at different speeds and pressures. The parameters such as pitch, diameter, and helix angle of the screw need to be optimized and designed according to the production requirements of polyethylene film masterbatch to improve the conveying efficiency and uniformity of the material. At the same time, the gap between the screw and the barrel should be reasonably controlled, generally between 0.1-0.3 millimeters, to prevent material leakage and backflow.

Corrosion resistance and wear resistance

Corrosion resistance measures: Due to the possibility of contact with corrosive additives such as antioxidants and lubricants during the production process, components such as the barrel and screw of the extruder that come into contact with the material need to be treated with corrosion resistance measures. The barrel is usually protected by lining it with stainless steel or spraying a corrosion-resistant coating. Stainless steel material has good corrosion resistance and oxidation resistance, which can effectively prevent the barrel from being corroded by chemical substances. The screw can be made of alloy steel with good corrosion resistance and surface treated, such as hard chromium plating or electroless nickel plating, to improve its corrosion resistance.

Wear resistant design: In the production process of polyethylene film masterbatch, there will be certain friction between the material and the screw and barrel, especially in the case of high-speed extrusion or adding fillers, the wear is more obvious. In order to improve the wear resistance of the equipment, the surface of the screw and barrel should have high hardness. Generally speaking, the hardness of the screw surface should reach HRC55-62, and the hardness of the inner surface of the barrel should reach HRC50-58. In addition, wear-resistant liners can be installed in the feeding section and easily worn parts of the barrel for regular replacement and to reduce equipment maintenance costs.

Automated Control and Monitoring

Control System: Equipped with advanced automation control systems such as PLC (Programmable Logic Controller) or DCS (Distributed Control System). These systems can achieve real-time monitoring and precise control of parameters such as temperature, pressure, screw speed, and material flow rate of the extruder. Operators can easily set and adjust production parameters through the human-machine interface (HMI), monitor and manage the production process, and improve production efficiency and product quality stability.

Quality inspection and feedback: Some high-end extruders are also equipped with online quality inspection equipment, such as laser thickness gauges, infrared spectroscopy analyzers, etc., which can detect the thickness, composition and other quality indicators of the film masterbatch in real time, and feedback the inspection data to the control system. The control system automatically adjusts production parameters based on feedback data to achieve closed-loop control and ensure that product quality meets standard requirements.

Formula ratio

The ratio of polyethylene film masterbatch may vary depending on different application requirements and product performance requirements. Here are some common examples and explanations of polyethylene film masterbatch ratios:

Ordinary polyethylene film masterbatch

Polyethylene resin: 90% -95%

Linear low-density polyethylene (LLDPE), low-density polyethylene (LDPE), or their blends are usually selected. LLDPE has good tensile strength and toughness, while LDPE has good transparency and flexibility. By mixing the two in appropriate proportions, film masterbatch with good comprehensive performance can be obtained.

Filler: 3% -8%

The commonly used filler is calcium carbonate (CaCO3), which can reduce costs while improving the rigidity and hardness of the film. When choosing calcium carbonate, attention should be paid to its particle size and surface treatment. Generally, the smaller the particle size, the less impact it has on the film properties, and the compatibility between surface treated calcium carbonate and polyethylene resin is better.

Antioxidant: 0.1% -0.5%

The function of antioxidants is to prevent oxidative degradation of polyethylene during processing and use, and to extend the service life of the film. Common antioxidants include hindered phenols and phosphites, which are usually used in combination to exert a synergistic effect and more effectively improve the antioxidant properties of films.

Lubricant: 0.5% -1%

Lubricants can improve the flowability of polyethylene resin during processing, reduce friction between materials and equipment, improve production efficiency, and make the film surface smoother. Common lubricants include stearic acid and its salts, fatty acid esters, etc.

Aging resistant polyethylene film masterbatch

Polyethylene resin: 88% -92%

Using LLDPE and LDPE as the base resins, adjust the ratio of the two according to the specific usage environment and performance requirements of the film. For example, in outdoor films that require higher aging resistance, the proportion of LLDPE may be appropriately increased to improve the tensile strength and tear resistance of the film.

Filler: 5% -8%

In addition to calcium carbonate, other fillers such as talcum powder can also be chosen. Talc powder has a sheet-like structure, which can improve the weather resistance and barrier properties of the film to a certain extent.

Antioxidant: 0.2% -0.5%

Similar to ordinary film masterbatch, but in anti-aging films, antioxidant varieties with higher temperature resistance and long-lasting antioxidant effects may be selected to better resist long-term thermal and photo oxidative aging.

Light stabilizer: 0.3% -1%

Light stabilizers are key additives for improving the aging resistance of thin films, mainly including ultraviolet absorbers and hindered amine light stabilizers (HALS). UV absorbers can absorb ultraviolet radiation, convert it into thermal energy, and emit it, while HALS inhibits the progress of photooxidation reactions by capturing free radicals, decomposing peroxides, and other methods. The combination of the two can significantly improve the light aging resistance of the film.

Lubricant: 0.5% -1%

The function is the same as the lubricant in ordinary film masterbatch, and the appropriate lubricant variety and dosage can be selected according to specific processing technology and equipment requirements.

Functional polyethylene film masterbatch (such as anti fog droplets, antibacterial, etc.)

Polyethylene resin: 85% -90%

Select the appropriate type and grade of polyethylene resin based on functional requirements and the ultimate use of the film. For example, for anti fog film that requires good transparency and flexibility, LDPE may be the main choice; For antibacterial films that require high strength and rigidity, the proportion of LLDPE may be increased or a blend of high-density polyethylene (HDPE) and LDPE may be used.

Filler: 3% -8%

The selection and function of fillers are similar to those of ordinary film masterbatch, but in some functional films, fillers with special properties may be selected. For example, in antibacterial films, fillers such as nano zinc oxide and nano silver with antibacterial functions can be selected, which can not only play a certain filling role but also endow the film with antibacterial properties.

Antioxidant: 0.1% -0.5%

Similar to the antioxidant in ordinary film masterbatch, it is used to prevent the oxidative degradation of polyethylene resin and ensure the stability of film performance.

Lubricant: 0.5% -1%

Help improve processing performance, make the film surface smooth, reduce friction, increase production efficiency and film quality.

Functional additives: 3% -10%

Anti fog droplet masterbatch: Generally, hydrophilic surfactants such as fatty acid glycerides, polyethylene glycol, etc. are added, which can form a uniform hydrophilic film on the surface of the film, allowing water droplets condensed on the film to quickly spread into a water film, thereby avoiding the scattering and refraction of light by water droplets, maintaining the transparency and anti fog effect of the film.

Antibacterial masterbatch: Add antibacterial agents, such as organic antibacterial agents (such as quaternary ammonium salts, biguanides, etc.) or inorganic antibacterial agents (such as silver based, copper based antibacterial agents, etc.). These antibacterial agents can inhibit or kill microorganisms such as bacteria and mold on the surface of the film, prevent bacterial growth and reproduction, and thus maintain the cleanliness and hygiene of the film.

The above ratios are for reference only. In actual production, adjustments and optimizations need to be made based on specific product requirements, production processes, equipment conditions, and other factors. At the same time, there may be differences in the performance of raw materials and additives produced by different manufacturers, and it is also necessary to determine the optimal ratio scheme through experiments and tests.

Applications

Polyethylene film masterbatch has a wide range of applications in various fields such as packaging, agriculture, industry, construction, and daily life. The following is a specific introduction:

Packaging field

Food packaging: It has good flexibility, transparency, and water resistance, which can effectively maintain the freshness and quality of food, such as being used to make various food packaging bags, cling films, etc.

Medical packaging: Good hygiene performance, high chemical stability, not easily reacting with drugs, can be used for blister packaging, inner packaging film, etc. of drugs, ensuring the quality and safety of drugs during storage and transportation.

Daily necessities packaging: widely used in the packaging of cosmetics, washing products and other daily necessities, such as packaging films, labels, etc., to protect products and beautify their appearance.

agriculture

Agricultural film: It is a commonly used covering material in agricultural production, which can provide insulation, moisture retention, transparency, pest control and other functions, helping to improve crop yield and quality. Common types include greenhouse film, plastic film, etc.

Seedling film: provides a suitable growth environment for seedlings, promotes their growth and development, and increases their survival rate.

Industrial sector

Electronic industry: Packaging materials, insulating films, etc. that can be used to manufacture electronic components, have good insulation and anti-static properties, and can protect electronic components from static electricity, dust, and other influences.

Automotive industry: Used for packaging automotive interior parts, protective films for automotive glass, etc., it has good weather resistance and wear resistance, and can protect automotive components from damage during transportation and storage.

Construction field

Waterproof coiled material: as one of the main raw materials of waterproof coiled material, the waterproof coiled material made of polyethylene film masterbatch has good waterproof performance, corrosion resistance and aging resistance, and is widely used in the waterproof engineering of roof, basement, toilet and other parts of buildings.

Thermal insulation material: can be used to manufacture thermal insulation film, which plays a role in thermal insulation by reflecting or absorbing heat, and improves the energy utilization efficiency of buildings.

Other areas

Disposable items: such as disposable tablecloths, garbage bags, etc., use their low cost, easy processing, and good performance to provide convenience for people’s daily lives.

Coating material: It can be used as a coating material to coat the surface of paper, fabric, etc., improving their waterproof, moisture-proof, wear-resistant and other properties.