PC masterbatch, also known as polycarbonate masterbatch, is a polymer material made from polycarbonate as the matrix resin, with various functional additives added, and processed through specific processes.

Types of PC masterbatch

In addition to the common, reinforced, flame-retardant, wear-resistant, conductive and other types mentioned earlier, there are also several common types of PC masterbatch:

Weather resistant PC masterbatch

Features: Added weather resistant agents such as UV absorbers, light stabilizers, etc., which can effectively resist the effects of climate factors such as UV rays, ozone, and high temperatures, prevent PC products from discoloration, brittleness, and decreased mechanical properties during long-term outdoor use, and have good aging resistance.

Application: Commonly used in outdoor building materials such as polycarbonate panels and curtain walls; Outdoor lamp casing; External components of automobiles, such as rearview mirror housings, lampshades, and other products that require long-term exposure to outdoor environments.

Optical grade PC masterbatch

Characteristics: It has extremely high transparency, low haze, good optical uniformity, and refractive index consistency. Its molecular chains are arranged neatly, with extremely low impurity content, ensuring minimal propagation loss of light and clear and undistorted imaging.

Application: Mainly used for manufacturing products with extremely high optical performance requirements, such as optical lenses, optical discs, display screen light guide plates, optical fibers, etc.

Antibacterial PC masterbatch

Features: Added antibacterial agents such as silver ion antibacterial agents, organic antibacterial agents, etc., which can inhibit the growth and reproduction of bacteria, molds and other microorganisms, effectively prevent the growth of bacteria on the surface of PC products, and maintain the hygiene and cleanliness of the products.

Application: Widely used in fields with high hygiene requirements such as medical equipment, food packaging, sanitary ware, and children’s toys.

Low warpage PC masterbatch

Characteristics: Through special formula design and processing technology, the shrinkage rate and crystallization performance of PC masterbatch have been adjusted, reducing the degree of warping and deformation of the product during the molding process, and improving the dimensional stability and appearance quality of the product.

Application: Suitable for manufacturing large flat products, precision components with complex structures, and electronic and electrical casings with high requirements for external flatness.

Degradable PC masterbatch

Characteristics: Degradable groups or additives are introduced into the PC molecular chain, allowing it to gradually decompose into small molecules under certain environmental conditions such as soil, water, microorganisms, etc., achieving natural degradation and reducing environmental pollution.

Application: It can be used in disposable packaging materials, agricultural films, biomedical materials and other fields, meets environmental requirements, and helps promote sustainable development.

Thermal conductive PC masterbatch

Features: High thermal conductivity fillers such as boron nitride, aluminum oxide, silicon carbide, etc. are added to give PC masterbatch good thermal conductivity, which can quickly dissipate heat, effectively reduce the temperature of the product during use, and improve the stability and reliability of the product.

Application: Commonly used in the field of electronic appliances, such as computer CPU heat sinks, mobile phone heat dissipation modules, LED lighting heat dissipation substrates, and other products that require good heat dissipation performance.

Toughened PC masterbatch

Characteristics: By adding toughening agents such as rubber elastomers, thermoplastic elastomers, etc., the toughness and impact resistance of PC masterbatch are improved, making it less prone to cracking or brittle fracture under external impact, while maintaining the original rigidity and heat resistance of PC.

Application: Widely used in automotive interior parts, sports equipment, safety helmets, luggage and other fields that require high toughness and impact resistance of products.

Smooth PC masterbatch

Features: Added slip agents such as fatty acid amides, silicone, etc., reducing the friction coefficient of the PC product surface, making it have good slip and demolding properties, easy to process and shape, and improving the feel and surface quality of the product.

Application: Commonly used in the production of plastic products, such as plastic films, pipes, injection molded products, etc., especially in products that require frequent demolding or have requirements for surface smoothness.

Antistatic PC masterbatch

Features: Added anti-static agent, can form a conductive film on the surface of PC products, quickly dissipate static electricity, prevent static electricity accumulation, and avoid dust adsorption, electric shock, fire and other problems caused by static electricity.

Application: Widely used in industries sensitive to static electricity such as electronics, chemicals, textiles, and food, such as packaging materials for electronic devices, packaging bags for chemical raw materials, and workwear for dust-free workshops.

Color PC masterbatch

Features: Various pigments or color powders are added, and after special dispersion treatment, the PC masterbatch has rich colors and good color stability, which can meet the needs of different users for product appearance color.

Application: Widely used in the production of plastic products with appearance and color requirements, such as plastic toys, stationery, household items, and automotive interior parts.

Formula ratio

The ratio of PC masterbatch may vary depending on different types, manufacturers, and specific product requirements. The following are some examples of the approximate ratio range of common types of PC masterbatch, which may need to be adjusted according to specific situations in actual production:

Enhance PC masterbatch

PC resin: 70% -90%, is the matrix material of the masterbatch, providing basic mechanical properties and molding processing performance.

Fiberglass: 10% -30%, used to enhance the strength and rigidity of materials, improve the mechanical properties of products, such as tensile strength, bending strength, etc.

Coupling agent: 0.5% -2%, improves the interfacial bonding force between glass fiber and PC resin, and enhances the reinforcement effect.

Other additives, such as lubricants, antioxidants, etc., usually account for 0.5% -2%, which helps improve processing performance and enhance product stability.

Flame retardant PC masterbatch

PC resin: 60% -85%, as the base material, endows the masterbatch with basic physical and processing properties.

Flame retardant: 15% -40%. Choose suitable flame retardants according to different flame retardant requirements, such as bromine based flame retardants, phosphorus based flame retardants, nitrogen based flame retardants, etc., to improve the flame retardant performance of PC materials and achieve the corresponding flame retardant level.

Synergistic agent: 0% -5%, used in combination with flame retardants to enhance flame retardancy. Common synergistic agents include antimony trioxide.

Other additives, such as anti drip agents and stabilizers, generally account for 0.5% -2% to prevent dripping during combustion and improve the stability and durability of the product.

Weather resistant PC masterbatch

PC resin: 80% -95%, is the main component of the masterbatch, providing the basic performance of the product.

Weathering agent: including UV absorbers, light stabilizers, etc., with a content usually ranging from 0.5% to 5%, can effectively absorb UV rays, inhibit photo oxidation reactions, and improve the weather resistance of PC products.

Antioxidants: 0.1% -1%, prevent oxidative degradation of PC resin during processing and use, and improve product stability.

Other additives: such as lubricants, pigments, etc., accounting for about 0.5% -2%, improve processing performance and product appearance.

Toughened PC masterbatch

PC resin: 70% -90%, providing basic rigidity and heat resistance for the masterbatch.

Toughening agent: 10% -30%, such as rubber elastomers, thermoplastic elastomers, etc., is a key component for improving the toughness and impact resistance of PC.

Compatibility agent: 0.5% -5%, used to improve the compatibility between PC resin and toughening agent, enhance the bonding strength between the two, and thus better exert the toughening effect.

Other additives, such as antioxidants and lubricants, account for 0.5% -2% and help improve the stability and processing performance of the product.

Conductive PC masterbatch

PC resin: 60% -90%, as the matrix of the masterbatch, endows the product with certain mechanical properties and molding processing performance.

Conductive fillers: 10% -40%, commonly used conductive fillers include carbon black, carbon fiber, metal powder, metal fiber, etc., which can form a conductive network in the PC matrix, making the PC masterbatch conductive.

Dispersant: 0.5% -5%, helps to evenly disperse conductive fillers in PC resin, improving the stability and consistency of conductivity.

Other additives, such as antioxidants and lubricants, account for 0.5% -2% to improve processing performance and product stability.

Optical grade PC masterbatch

PC resin: 98% -99.9%, usually using high-purity and high transparency PC resin, which is the basis for ensuring optical performance.

Optical additives: 0.1% -2%, including refractive index modifiers, anti fog agents, etc., used to precisely adjust the optical properties of PC, such as refractive index, haze, etc., to meet the requirements of different optical applications.

Antibacterial PC masterbatch

PC resin: 85% -98%, as the main material of the masterbatch, providing basic physical and processing properties.

Antibacterial agent: 0.5% -10%, the amount added may vary depending on the antibacterial requirements and the type of antibacterial agent. Common antibacterial agents such as silver ion antibacterial agents and organic antibacterial agents can inhibit the growth and reproduction of microorganisms such as bacteria and molds.

Dispersant: 0.1% -1%, helps to evenly disperse antibacterial agents in PC resin, improving the stability and durability of antibacterial effects.

Low warpage PC masterbatch

PC resin: 80% -95%, is the main component of the masterbatch, providing the basic performance of the product.

Low warpage additives: 3% -15%. These additives are usually special nucleating agents or crystallization regulators that can change the crystallization behavior of PC, reduce the difference in shrinkage rate during the molding process, and thus reduce warpage deformation.

Other additives, such as lubricants, antioxidants, etc., account for about 0.5% -2% to improve processing performance and product stability.

Degradable PC masterbatch

PC resin: 60% -90%, suitable PC resin can be selected as the matrix, and different molecular weights and properties of PC can be chosen according to specific needs.

Degradable additives: 10% -40%, including degradable polyester, starch, etc. These additives can promote the degradation of PC under certain conditions, gradually decomposing it into small molecular substances in the environment.

Compatibilizer: 0.5% -5%, used to improve the compatibility between PC resin and degradable additives, enhance material performance and stability.

Thermal conductive PC masterbatch

PC resin: 70% -90%, serving as the matrix for the masterbatch, providing the basic mechanical and processing properties of the product.

Thermal conductive fillers: 10% -30%, such as boron nitride, aluminum oxide, silicon carbide, etc. These fillers have high thermal conductivity and can form thermal conductive channels in the PC matrix, improving the thermal conductivity of the material.

Surface treatment agent: 0.5% -2%, used for surface treatment of thermal conductive fillers, improving their compatibility and dispersibility with PC resin, and enhancing thermal conductivity.

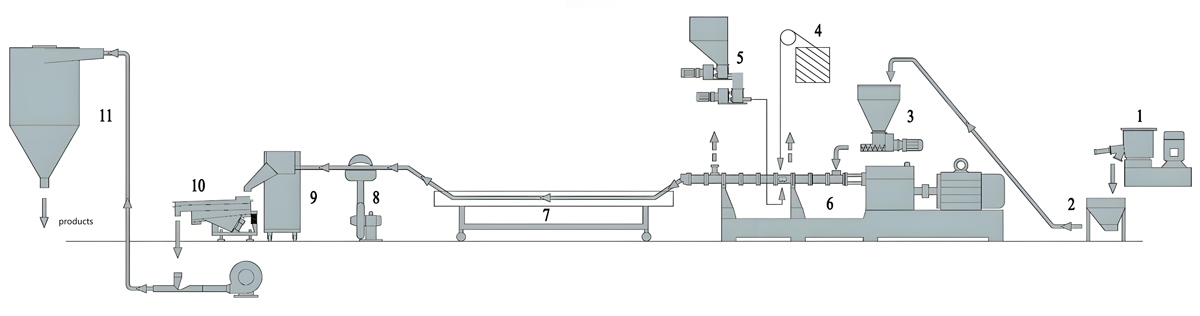

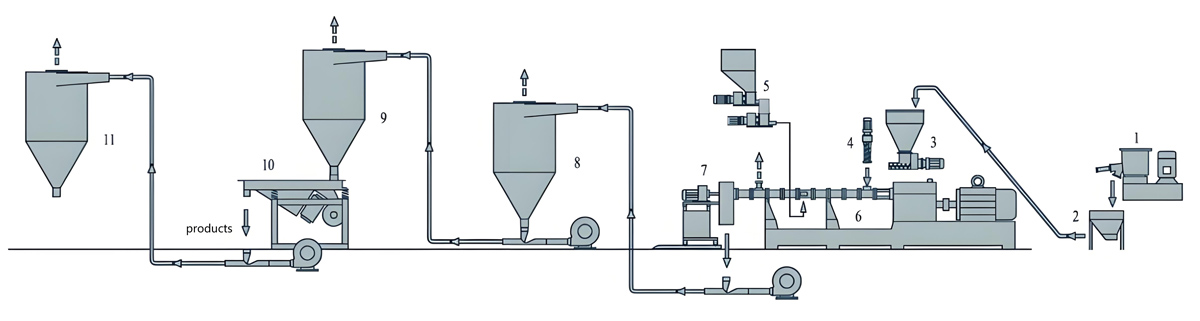

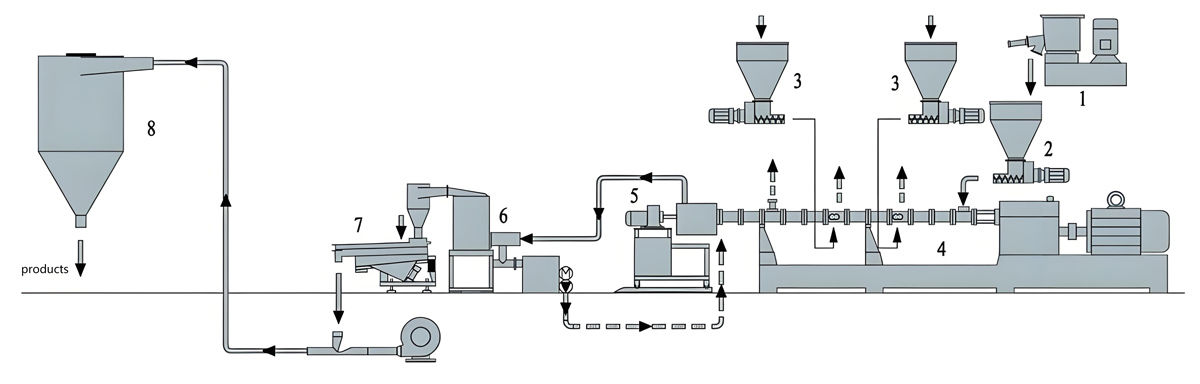

Production process

The production process of PC masterbatch usually includes the following main steps:

raw material preparation

Resin selection: Choose the appropriate PC resin based on the type and performance requirements of the PC masterbatch. Generally, resins are required to have good fluidity, thermal stability, and mechanical properties.

Additive selection: For different types of PC masterbatch, add corresponding additives such as reinforcing agents, flame retardants, toughening agents, weather resistant agents, color powders, etc. These additives need to have good dispersibility and compatibility with PC resin.

Mixing of ingredients

Accurate measurement: According to the set formula, high-precision measuring equipment is used to accurately measure PC resin and various additives. Ensure the accurate proportion of each component to ensure the stability of product performance.

Pre mixing: Pour the measured raw materials into a high-speed mixer for pre mixing. By high-speed stirring, the PC resin and additives are initially uniformly mixed to prepare for the subsequent processing.

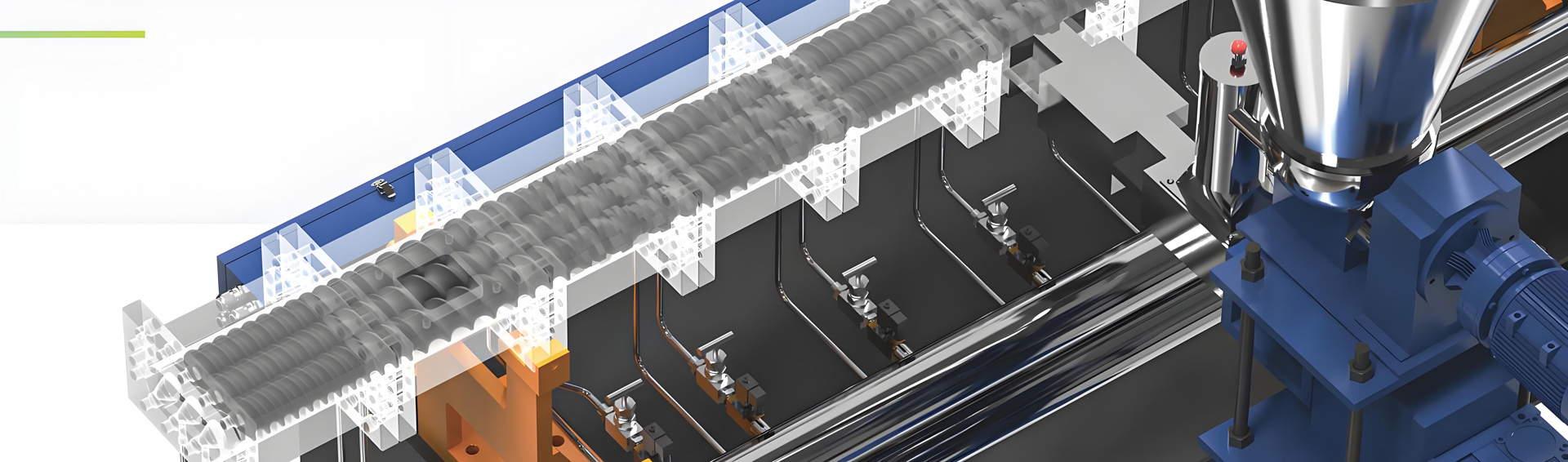

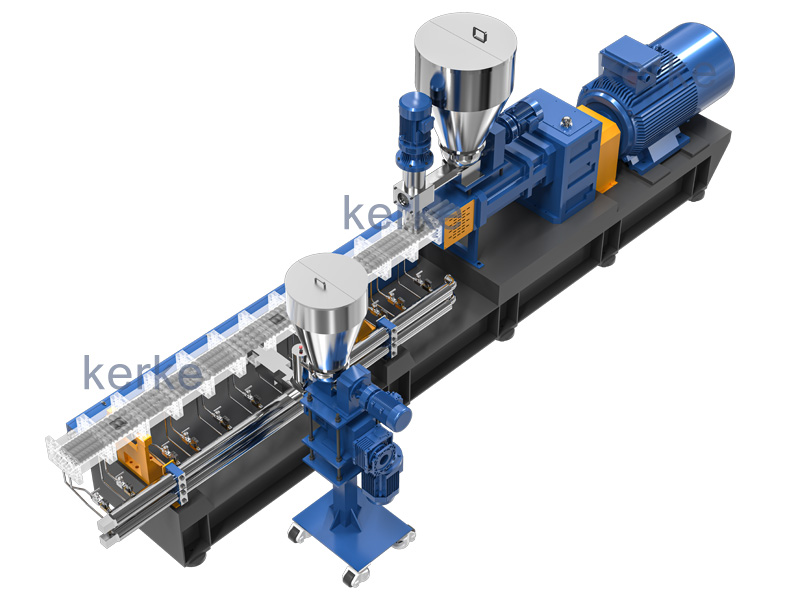

Melt extrusion

Heating and melting: Add the pre mixed raw materials into a twin-screw extruder. The barrel of the extruder heats the raw materials to the melting temperature of PC resin, usually between 250-320 ℃, through electric heating or other heating methods. At this temperature, PC resin is in a molten state and fully mixed with additives.

Screw extrusion: Under the action of a twin-screw extruder, the molten material moves forward under the push of the screw. The parameters such as screw speed and aspect ratio can affect the mixing effect and extrusion quality of materials. Meanwhile, during the extrusion process, an appropriate amount of lubricants and other additives can be added as needed to improve the flowability and processing performance of the material.

Filtration and impurity removal: In order to ensure the quality of products, filtering devices, such as filter screen and filter element, are usually set during the extrusion process to remove impurities, gel and other insoluble particles in materials and improve the purity of PC master batch.

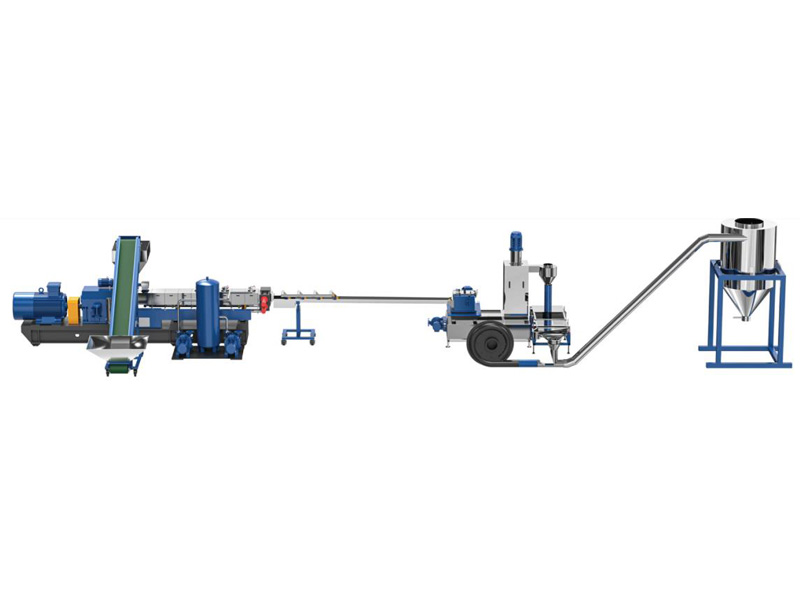

Cooling granulation

Water or air cooling: The extruded PC masterbatch is usually cooled by water or air cooling. Water cooling is the process of cooling the extruded strip material through a water tank, with a fast cooling rate. However, it is important to control the water temperature to prevent defects on the surface of the masterbatch. Air cooling is the process of blowing cold air towards the extruded strip material through a fan. The cooling speed is relatively slow, but it is suitable for some products that do not require high cooling speed.

Granulation: The cooled strip is pelletized by a pelletizer. The cutting tool of the granulator is adjusted according to the needs to cut the length of the granules. Generally, the particle size of PC masterbatch is around 2-5mm. During the granulation process, it is necessary to ensure the uniformity and regularity of the granulation to improve the appearance quality of the product.

Packaging and storage

Screening and packaging: The PC masterbatch after cutting is screened through a vibrating screen to remove particles that are too large or too small, ensuring the consistency of the product’s particle size. Then package the qualified masterbatch, usually using plastic woven bags or composite packaging bags, to prevent the product from getting damp, oxidized, etc.

Quality inspection: Before packaging, PC masterbatch needs to undergo quality inspection, including testing of appearance, particle size, flowability, mechanical properties, thermal properties, and other aspects. Only products that meet the standard requirements in all indicators can be stored and sold.

There may be slight differences in the production process of different types of PC masterbatch. For example, when producing optical grade PC masterbatch, higher requirements are placed on the purity of raw materials and the cleanliness of the production environment; When producing thermal conductive PC masterbatch, it is necessary to pay special attention to the dispersion uniformity of thermal conductive fillers.

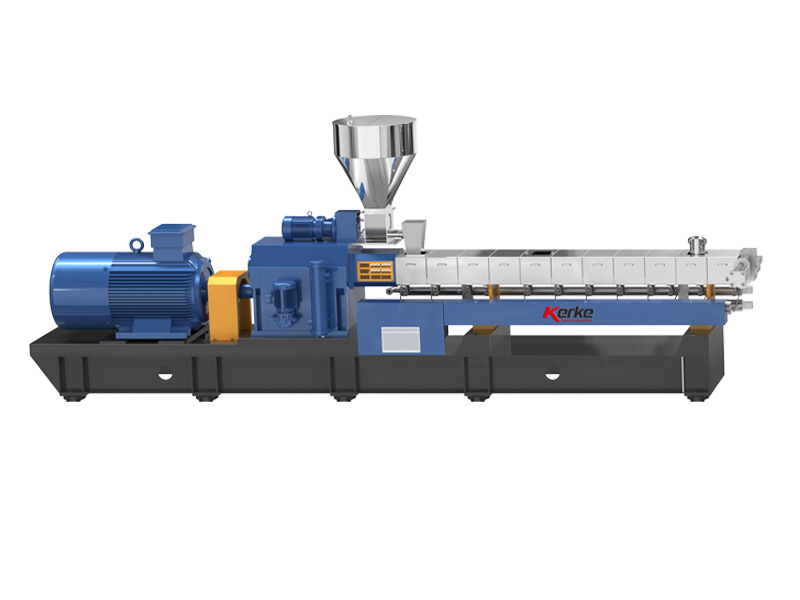

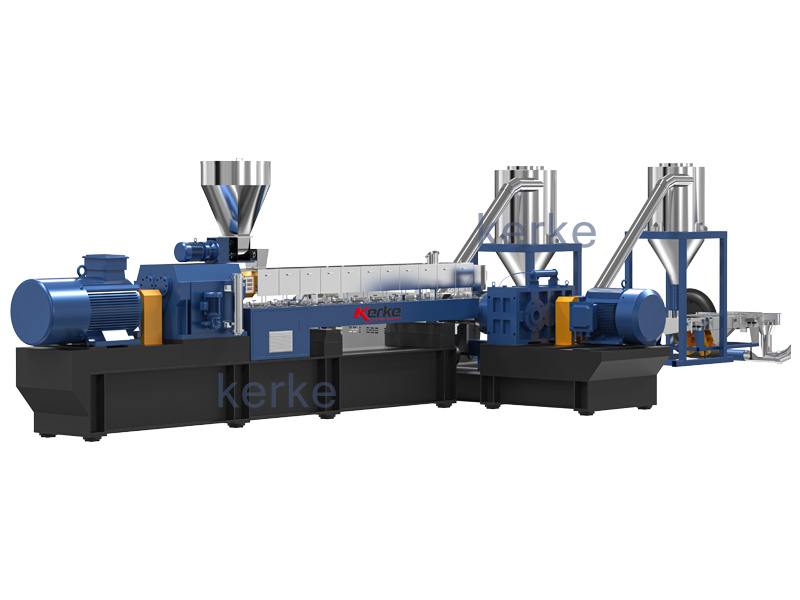

PC masterbatch extruder

Kerke’s masterbatch extruder can be used to produce PC masterbatch. Our PC masterbatch extruder has multiple models to choose from, which can meet different production requirements.

-

Laboratory Twin Screw Extruder

When will you need a lab twin screw extruder? If you want to make trials and tests of…

-

Parallel Twin Screw Extruder

Our Parallel Co-rotating twin screw extruder is designed for compounding and masterbatch making with an output capacity from…

-

Triple (3 screws) Extruder

3 Screws extruder is a new technology that has many advantages. The triple screw extruder is mainly used…

-

Double-Stage Extrusion System

Mother-baby extrusion system is designed for special materials which can not process on one stage extruder, the first…

-

Banbury Kneader Compounding Line

Our kneader + extruder is designed for making special applications with an output capacity from 30kg/h to 1000kg/h.…

-

Cutting System / Pelletizing System

Different material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of…

Production equipment and requirements

The production equipment for PC masterbatch mainly includes raw material processing equipment, mixing equipment, extrusion equipment, cooling equipment, cutting equipment, packaging equipment, etc. The following are specific introductions and corresponding requirements:

material handling equipment

Equipment: including high-speed mixers, dehumidifiers, dryers, etc.

Requirement: The high-speed mixer should have the ability to mix materials evenly in a short period of time, and the design of the mixing blades should be conducive to the full flipping of the materials. The dehumidification dryer should be able to accurately control the temperature and drying time to ensure that the PC resin and additives reach the specified moisture content. Generally, the moisture content of the PC resin is required to be controlled below 0.02% to avoid moisture causing hydrolysis of the PC during processing and affecting product performance.

mixing equipment

Equipment: Common feeding systems include twin-screw extruders and high-speed mixers.

Requirement: The feeding system should be able to accurately control the feeding amount of various raw materials to ensure the accuracy of the formula. Usually, a weight loss feeder is used, and the accuracy can reach within ± 0.5%. In addition to having good stirring and mixing functions, high-speed mixers also need to have good sealing performance to prevent material leakage and dust flying.

Extrusion equipment

Equipment: Mainly twin-screw extruders.

Requirement: The twin-screw extruder should have sufficient extrusion capacity and mixing effect, and the aspect ratio of the screw is generally between 30-48 to ensure that the material can be fully melted, mixed, and reacted during the extrusion process. At the same time, the heating and cooling system of the extruder should be able to accurately control the temperature, with a temperature control accuracy within ± 2 ℃, to ensure the stable quality of PC masterbatch. In addition, the screw and barrel of the extruder need to be made of wear-resistant and corrosion-resistant materials to meet the processing requirements of PC resin and additives.

Cooling equipment

Equipment: divided into water-cooled equipment and air-cooled equipment. Water cooling equipment mainly includes water tanks, cooling water pumps, etc; Air cooling equipment mainly includes fans, cooling pipes, etc.

Requirement: The water tank of the water-cooled equipment should ensure the fluidity and temperature uniformity of the water, and the water temperature is generally controlled between 15-30 ℃. The flow rate and pressure of the cooling water pump should meet the production requirements to ensure timely cooling and shaping of the extruded PC masterbatch. The fan of the air-cooled equipment should be able to provide sufficient air volume, with a wind speed generally between 5-10m/s, so that the PC masterbatch can be cooled to the specified temperature within a certain period of time.

Granulation equipment

Equipment: Common ones include hot pelletizers and cold pelletizers.

Requirement: The cutting tool of the hot cutting machine should be sharp, and the cutting speed should match the extrusion speed to ensure that the PC masterbatch particles cut out have uniform particle size and smooth appearance. The cold pelletizer needs to cool the PC strip to a certain temperature before pelletizing, usually between 40-60 ℃, and then perform pelletizing with a precision requirement of ± 0.5mm.

Packaging Equipment

Equipment: including automatic packaging machines, sealing machines, measuring scales, etc.

Requirement: The packaging speed of the automatic packaging machine should meet the requirements of production efficiency, generally packaging 5-10 bags per minute. The accuracy of the measuring scale should be high, and it can accurately weigh the weight of PC masterbatch with an error controlled within ± 0.1%. The sealing quality of the sealing machine should be good, ensuring that the packaging bag is tightly sealed and preventing the product from getting damp or oxidized.

In addition, the layout of the entire production equipment should be reasonable, in line with the process flow, and easy to operate and maintain. At the same time, in order to ensure the cleanliness of the production environment and reduce the impact of impurities on the quality of PC masterbatch, the production workshop should be kept relatively closed and equipped with an air purification system.

Application

PC masterbatch has various excellent properties, such as high transparency, high strength, high heat resistance, and good electrical insulation, so it has a wide range of applications in multiple fields. The following are some of the main application areas:

Electronic and electrical field

Shell material: PC masterbatch can be used to produce shells for electronic devices such as computers, mobile phones, and televisions. Its high heat resistance and strength can protect internal electronic components, while its good appearance quality and processing performance can meet the needs of different styling designs.

Connectors and sockets: PC masterbatch has excellent electrical insulation and mechanical properties, which can ensure the safety and reliability of connectors and sockets during long-term use, and are not prone to problems such as leakage and deformation.

Automotive industry field

Car lampshade: The lampshade made of PC masterbatch has high transparency, good weather resistance, and impact resistance, which can effectively protect the light bulb and provide clear light transmission, enhancing the safety of car driving.

Interior parts, such as car dashboards, door handles, seat backrests, etc., are often produced using PC masterbatch. PC masterbatch can achieve various colors and textures by adding different additives, meeting the personalized design needs of automotive interiors, and has good wear resistance and chemical corrosion resistance.

Optical field

Optical lenses: PC masterbatch has high refractive index and low birefringence characteristics, making it suitable for manufacturing various optical lenses such as camera lenses, projector lenses, etc. Its excellent optical performance can ensure clear and accurate images.

Optical disc: PC masterbatch is one of the main materials used to manufacture optical discs. With its high purity and excellent optical properties, high-density storage and fast reading of data can be achieved.

Construction field

Sunshine board: PC sunshine board has good transparency, insulation and impact resistance, and is widely used in fields such as building skylights, greenhouses, sound barriers, etc. PC masterbatch can improve the weather resistance and service life of solar panels by adding additives such as UV absorbers.

Decorative board: PC decorative board has rich colors and good surface texture, and can be used for interior and exterior wall decoration, ceiling decoration, etc. of buildings. It has good processing performance and can be made into decorative panels of various shapes and sizes to meet the needs of different architectural styles.

Medical device field

Medical transparent containers: Transparent containers made of PC masterbatch, such as medical syringes, infusion bottles, blood bags, etc., have the advantages of high transparency, non toxicity, odorlessness, and chemical corrosion resistance, which can meet the strict requirements of medical devices for safety and hygiene.

Medical instrument casing: The instrument casing produced by PC masterbatch not only has good mechanical properties and appearance quality, but also can be improved by adding special additives such as antibacterial agents to enhance the antibacterial performance of the casing, prevent bacterial growth, and ensure the safety of medical device use.