We Know Compounding Extruder

Over 12 Years, We focus on parallel co-rotating compounding extruder. You deserve the best price and service.

Over 12 Years, We focus on parallel co-rotating compounding extruder. You deserve the best price and service.

WHO WE ARE

Nanjing Kerke Extrusion Equipment Co., Ltd (WANPLAS Group) is a High-Tech company, which is composed of a well-experienced team in R&D design, manufacturing technique, and sales service, and based on the twin screw extruder industry for many years.

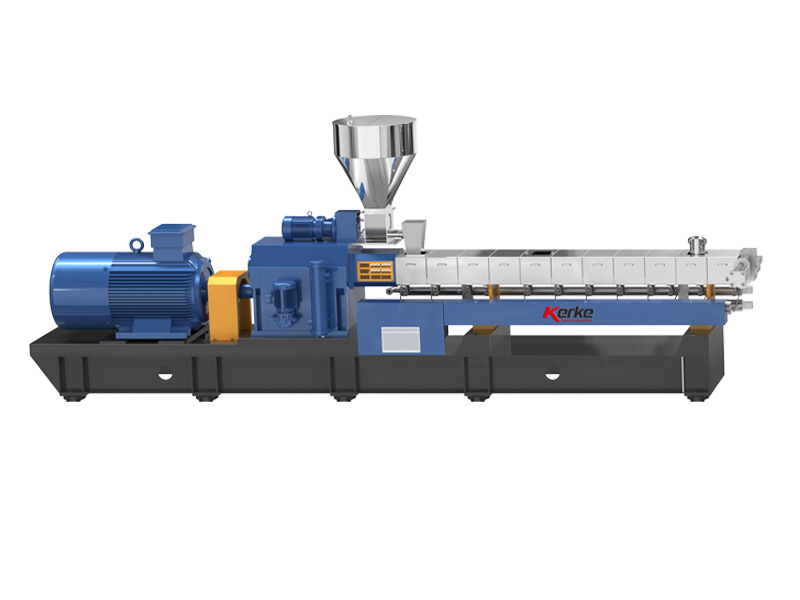

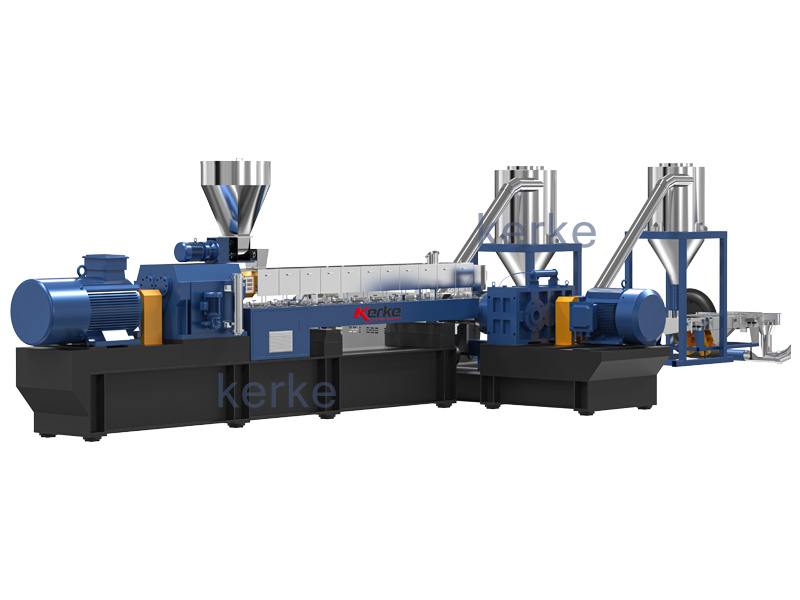

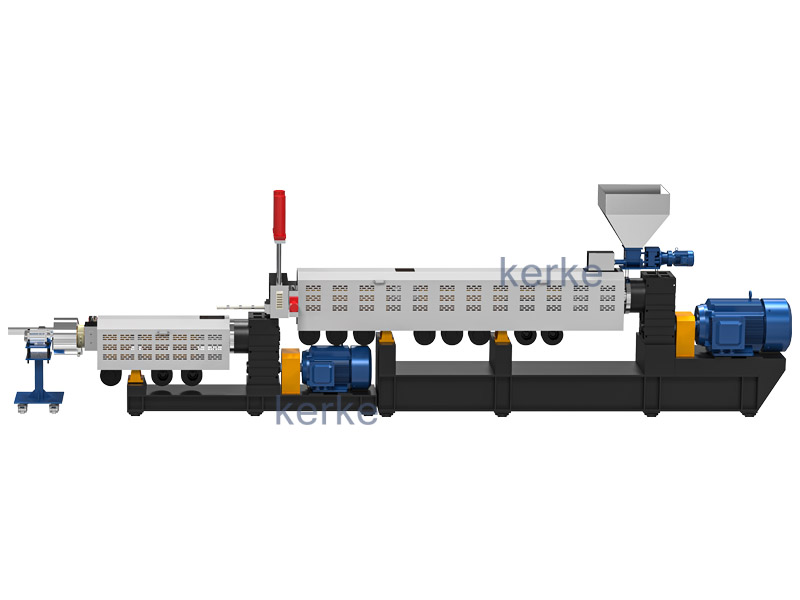

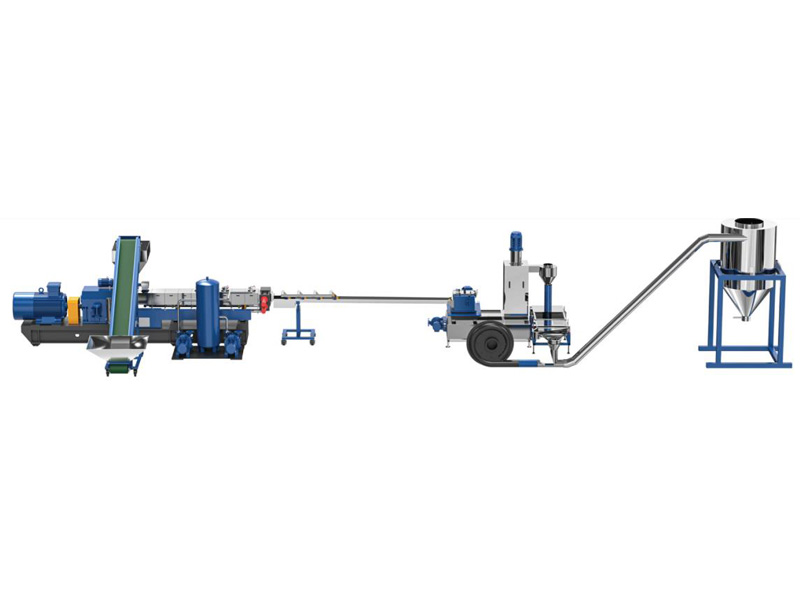

Our production series contain single screw extruder, co-rotating twin-screw compounding extruder KTE series from KTE-16B to KTE-135D, KTE/SE two-stage compounding line, KUW underwater pelletizing system, SE series single screw extruder, auxiliary equipment, etc.

WHAT WE DO

We are devoted to highly active single, twin screw, and compounding extruders, at the same time completely plant manufacture and interrelated technique, until the turn-key project.

We use a twin screw extruder which can make compounding and sheet extruder in one step, not like the single extruder, you should make compounded granules, then make the sheet.

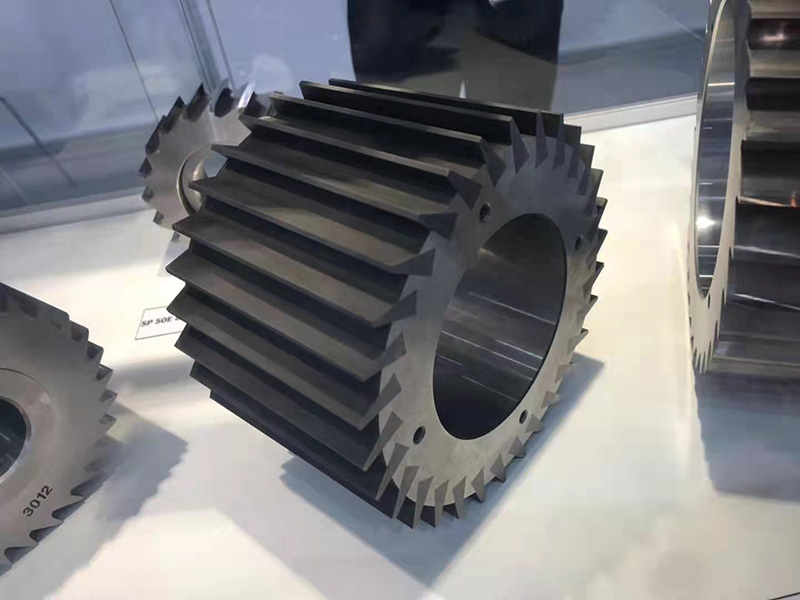

Kerke can provide the twin screw extruder auxiliary equipment to customers. Such as the high-speed mixer, the plastic granulator, the pulverizer, the extruder core parts, and the water chiller.

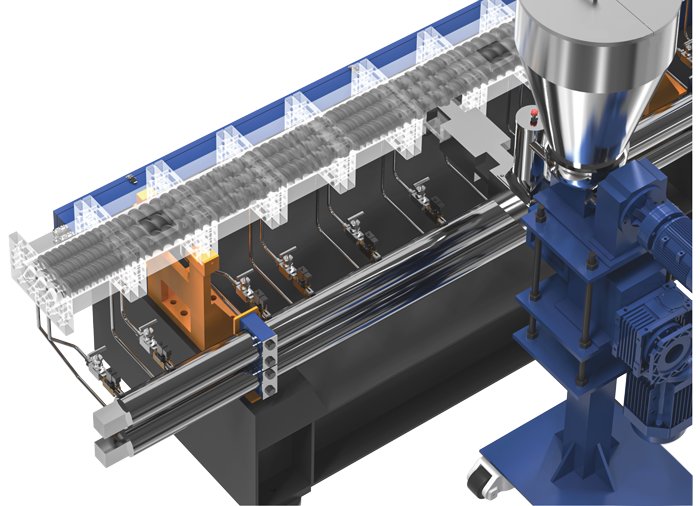

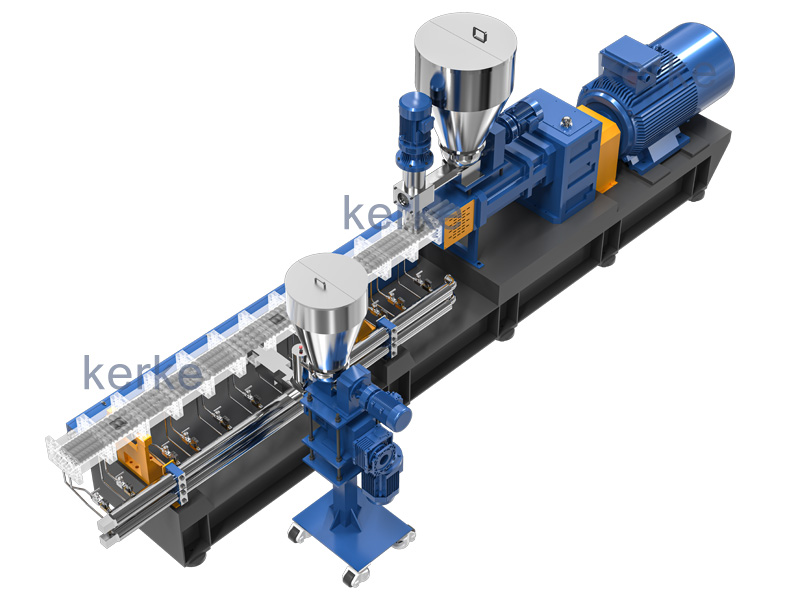

According to the processing material system and process formula requirements, its aspect ratio, barrel structure, screw arrangement, exhaust quantity and position, feeding method, electrical control method, etc. can all be optimized and reasonably configured.

The computer-aided designed screw assembly is a kneading co-type with excellent self-cleaning function and good interchangeability. Through appropriate and reasonable combination, it can realize material transportation, plasticization, shearing, dispersion, homogenization, exhaust, pressure building, etc.

The granulation system can be used in a variety of ways to meet the requirements, including water-cooled strand pelletizing, air-cooled strand pelletizing, air-cooled die face hot cutting, water ring die face hot cutting, eccentric water mist hot cutting, underwater granulation system, etc.

Kerke Extrusion Equipment Co., Ltd

When will you need a lab twin screw extruder? If you want to make trials and tests of your formula…

Our Parallel Co-rotating twin screw extruder is designed for compounding and masterbatch making with an output capacity from 30kg/h to…

3 Screws extruder is a new technology that has many advantages. The triple screw extruder is mainly used for special…

Mother-baby extrusion system is designed for special materials which can not process on one stage extruder, the first stage is…

Our single screw extruder is mainly used for plastic recycling with an output capacity from 30kg/h to 800kg/h. When you…

Different material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of each cutting…

According to the different states of the materials, the feeding system adopts a variety of structural forms: single screw, twin screw, twin screw non-meshing type, hollow spring type, two-stage type and metering pump and other volumetric metering feeding. It can also be equipped with loss-in-weight metering to meet higher metering requirements.

KERKE

1.

The efficient production capacity and precise control of materials of screw extruders make them key equipment in masterbatch production.

2.

Screw extruders can mix two or more different plastics to obtain plastics with superior performance.

3.

Screw extruders can be used to produce various extruded foods, food fillings, and plastic recycling industries.

19997+

Square Meters of Our Factory

2000+

Machines Running Worldwide

70+

Countries of Our Customer

100+

Numbers of Our Team

TRUSTED BY

Kerke Extrusion Equipment

From 1st March 2017. Kerke becomes a reserved trademark, we stepped into the next stage of our internal brand target. Kerke will become a time-honored trademark in the twin screw extruder field, you will get better quality extruder and better service from Kerke.

Enhancing cohesive force and gathering power from teamwork, 50 workers from Nanjing Kerke, leaded by the general manager, Lu Gang arrive Yizheng Tianle Lake Holiday Resort on Martch 25th 2017 for outdoor extending.

Welcome Your VisitBooth: 1A-121Time: 2023.6.12-6.15Add: Riyadh InternationalConvention & ExhibitionCenter, Kingdom ofSaudi Arabia