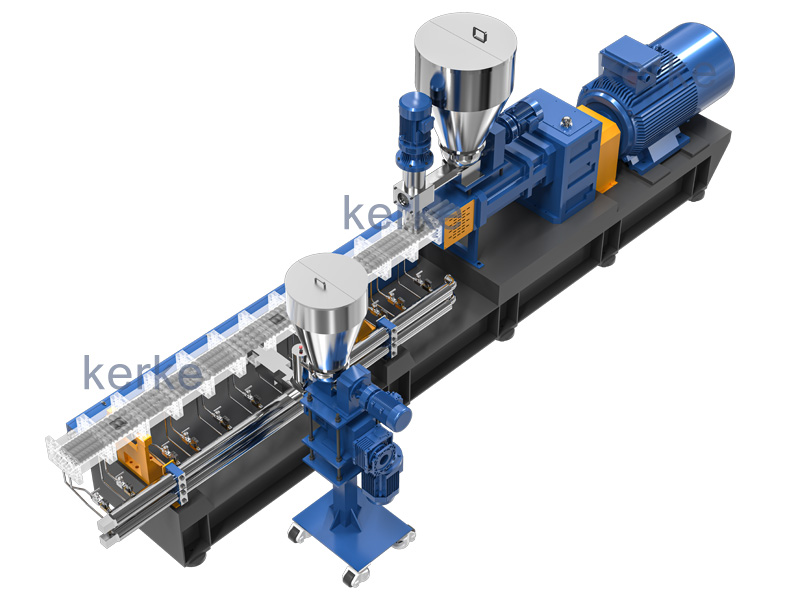

3 Screws extruder is a new technology that has many advantages. The triple screw extruder is mainly used for special applications with good dispersion and higher output

- Filler Masterbatch (High Caco3)

- Black Masterbatch

Why 3 screws extruder?

3 screw extruder has some advantages for special applications, parallel twin screw extruder was a long-time technology, but for some special applications the twin screw extruder can not process so well, we have 3 screws.

Advantages of 3 screws extruder

- Better dispersion

- Higher output

Main technical parameter

| Model | Screw Diamter 【mm】 | D/d 【mm】 | Maximum Speed 【rpm】 | Motor 【Kw】 | Torque 【N.m】 | Output 【Kg/h】 |

| KTET-36B | 35.6 | 1.51 | 600 | 55/75 | 7.8~9 | 100~300 |

| KTET-36D | 35.6 | 1.51 | 600 | 75/90 | 7.8~9 | 200~500 |

| KTET-50B | 50.5 | 1.55 | 600 | 90/132 | 7.8~9 | 300~800 |

| KTET-50D | 50.5 | 1.55 | 600 | 132/160 | 7.8~9 | 400~1200 |

| KTET-65B | 62.4 | 1.54 | 600 | 132/160 | 9~11.8 | 500~1500 |

| KTET-65D | 62.4 | 1.54 | 600 | 200/250 | 9~11.8 | 600~1800 |

| KTET-75B | 71 | 1.51 | 600 | 200/315 | 9~11.8 | 800~2000 |

| KTET-75D | 71 | 1.51 | 600 | 315/500 | 9~11.8 | 1000~3000 |