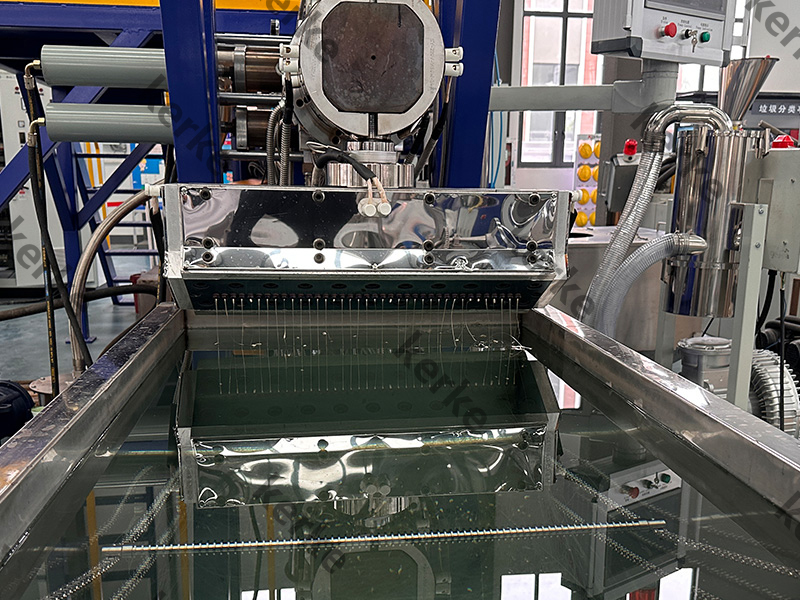

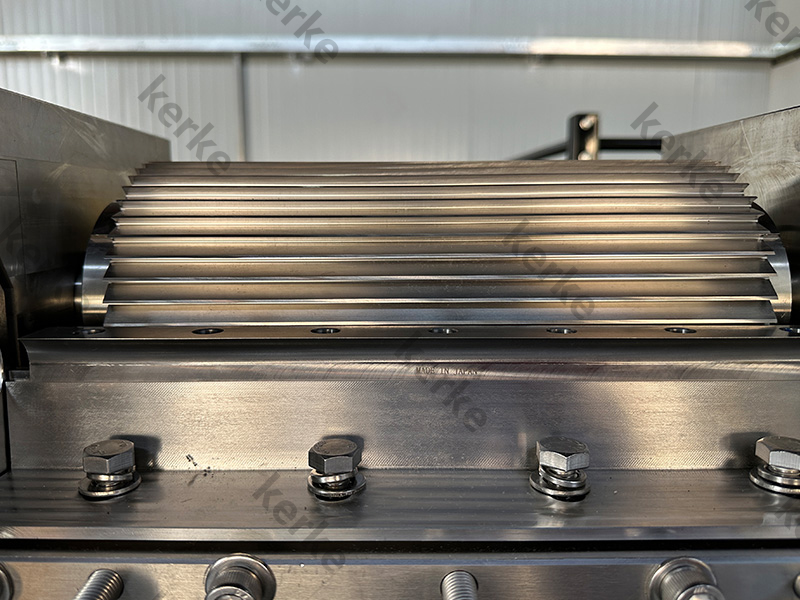

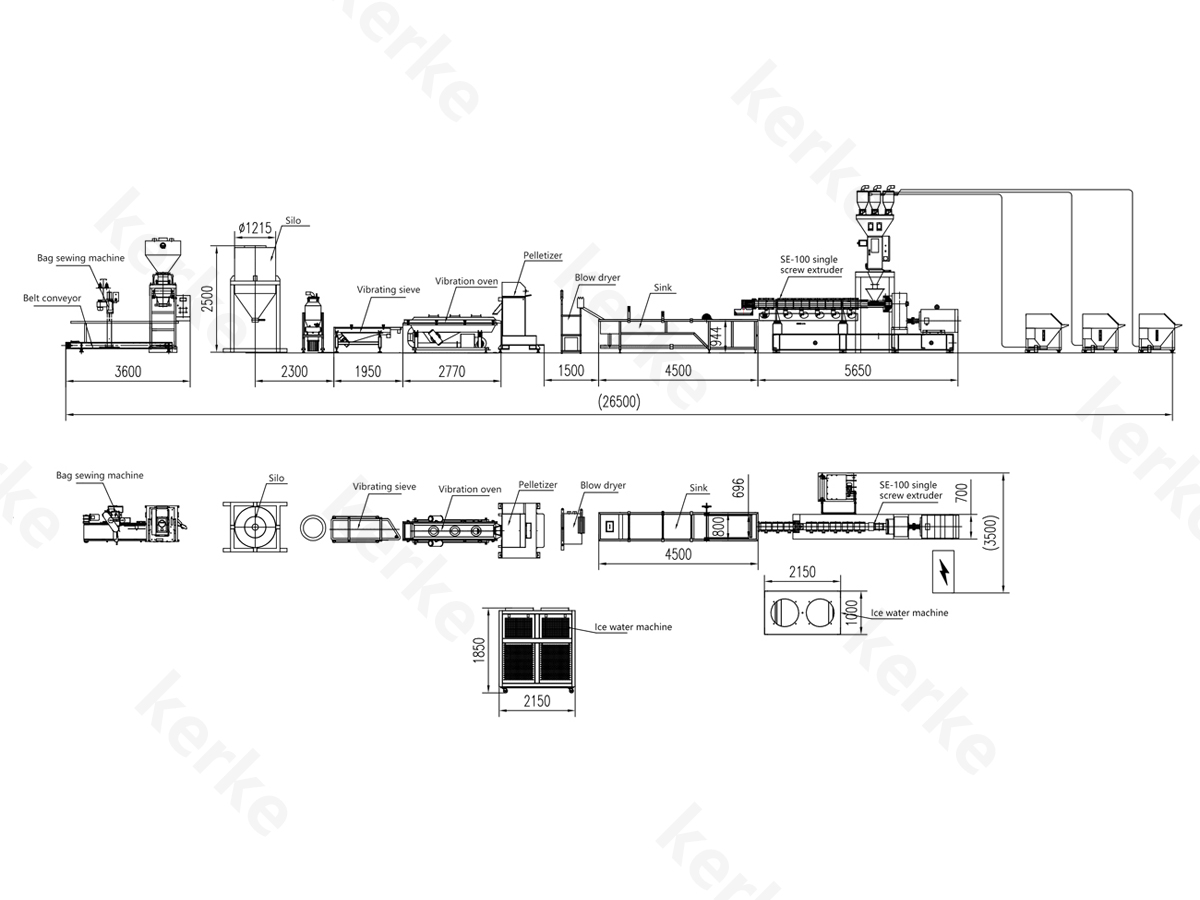

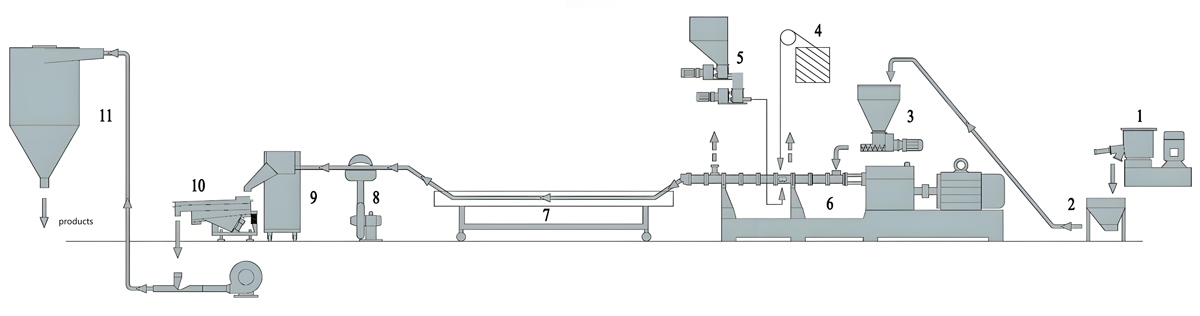

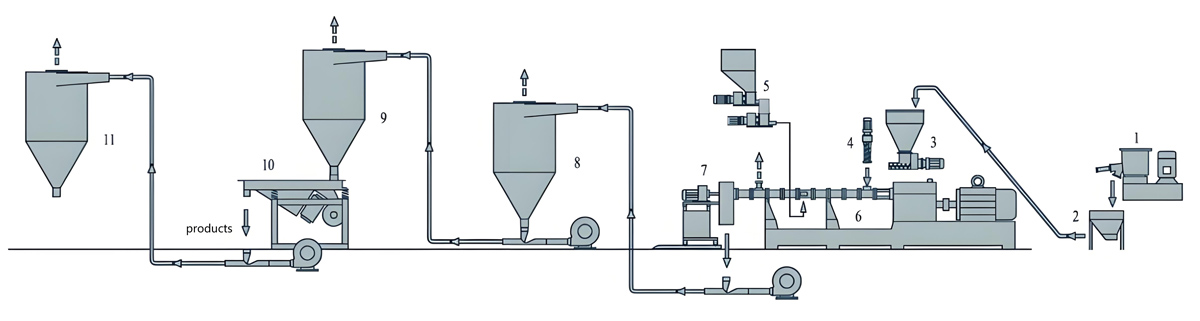

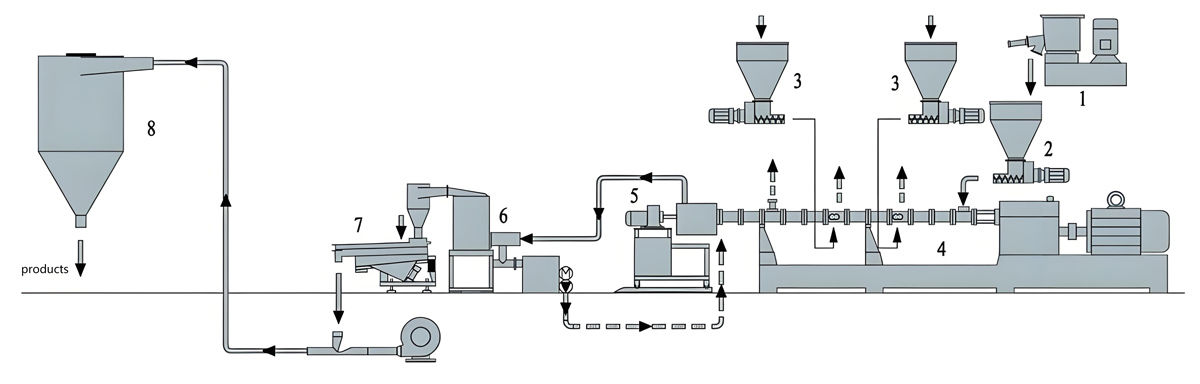

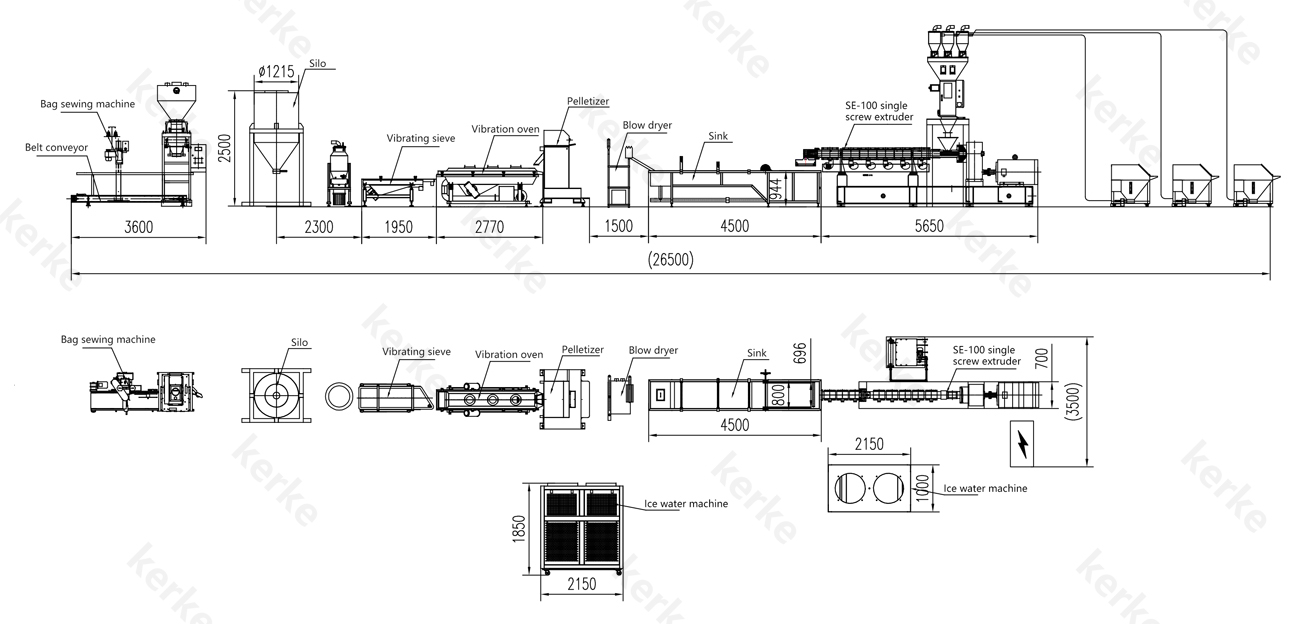

The SE-100 single screw extruder is the core part of the production line, which consists of a bracket, a drive group and a screw extruder body. The drive group drives the SE-100 single screw extruder body to operate. The extruder body includes an outer barrel, a screw group and a discharge mechanism, which can extrude the melted material and form material strips.

Different from ordinary masterbatch extruders for materials such as PP, PS, PET, etc., the micro pellet production line can produce smaller micro pellet masterbatch raw materials for subsequent foaming production.

Applications

Mainly used for the production of EPP, EPS, EPO, EPET, ETPU and other supercritical continuous reactor foaming particles.

Details