PVC masterbatch is a form of polyvinyl chloride (PVC), which is a granular product made by processing PVC resin as the matrix and adding various additives and additives. Usually white or slightly yellow particles, there are also other color particles made by adding color masterbatch according to demand.

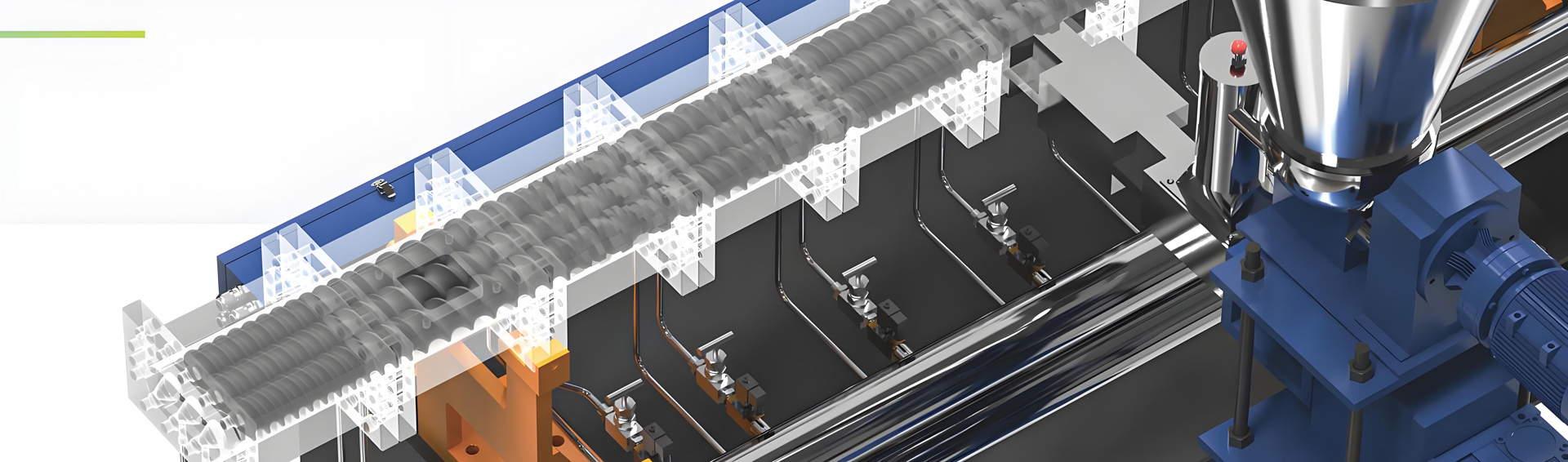

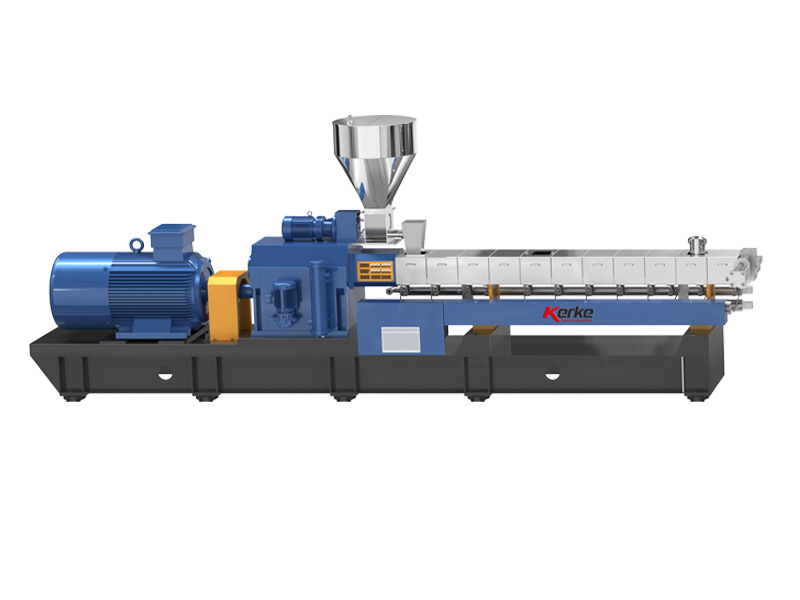

PVC masterbatch extruder

Kerke’s masterbatch extruder can be used to produce PVC masterbatch. Our PVC masterbatch extruder has multiple models to choose from, which can meet different production requirements.

-

Extrusora de doble husillo para laboratorio

¿Cuándo necesitará una extrusora de doble husillo de laboratorio? Si desea realizar ensayos y pruebas de...

-

Extrusora de doble husillo paralelo

Nuestra extrusora de doble husillo paralelo corrotante está diseñada para la fabricación de compuestos y...

-

Extrusor triple (3 tornillos)

La extrusora de 3 tornillos es una nueva tecnología que tiene muchas ventajas. La extrusora de triple tornillo se utiliza principalmente...

-

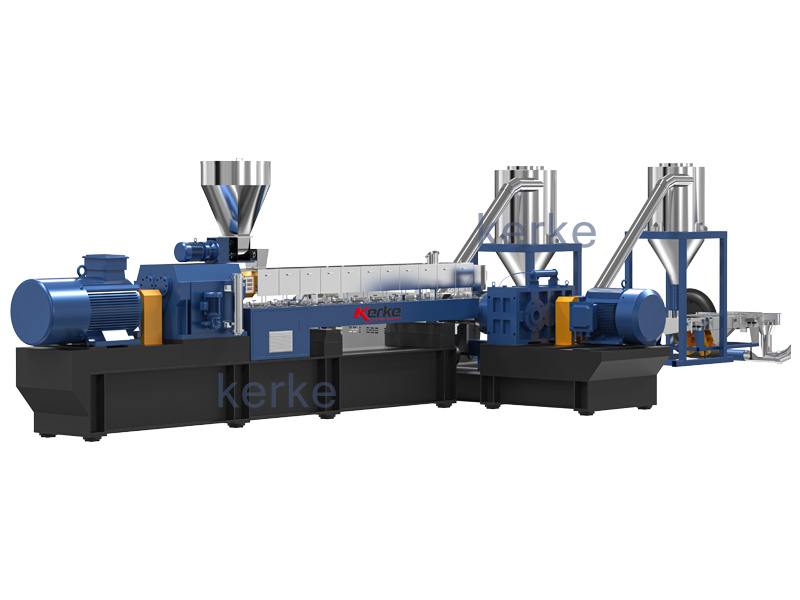

Sistema de extrusión de doble etapa

El sistema de extrusión madre-bebé está diseñado para materiales especiales que no pueden procesarse en una extrusora de una etapa,...

-

Línea de amasado Banbury

Nuestra amasadora + extrusora está diseñada para realizar aplicaciones especiales con una capacidad de producción de 30kg/h a 1000kg/h....

-

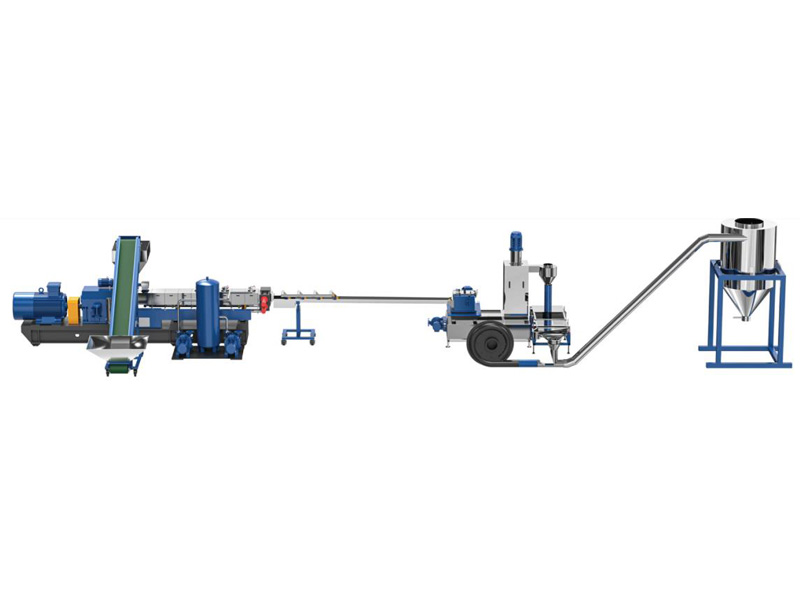

Sistema de corte / Sistema de granulación

Diferentes materiales necesitan diferentes sistemas de corte, Kerke ofrece todo tipo de sistemas de corte, aquí está la explicación de...

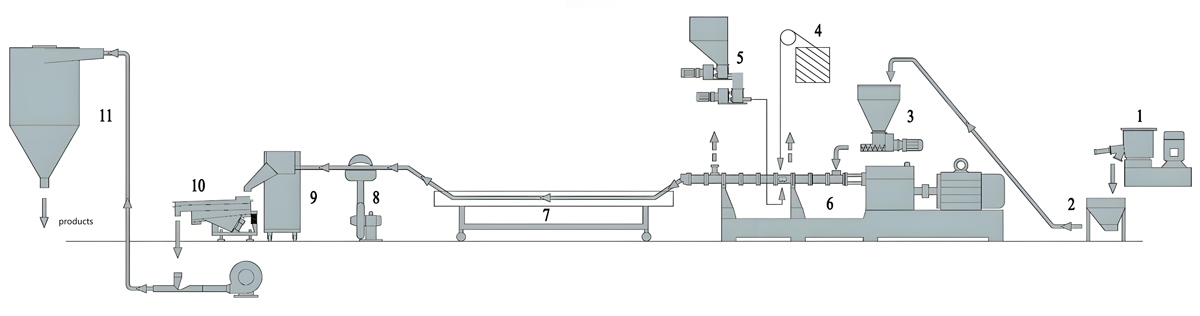

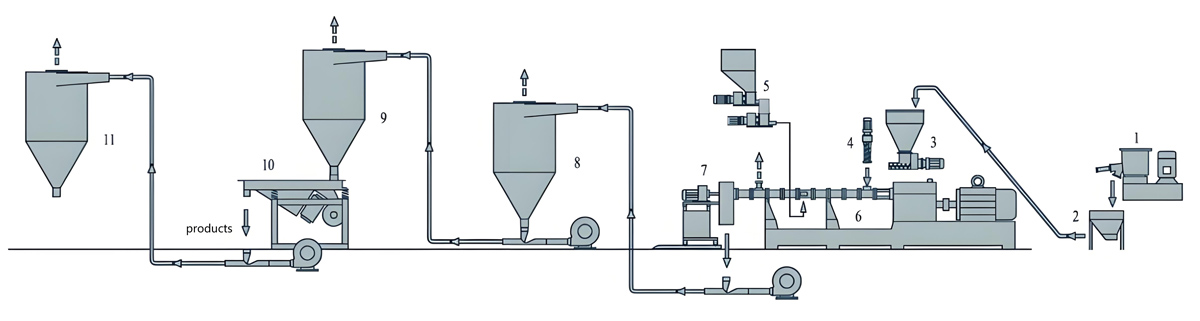

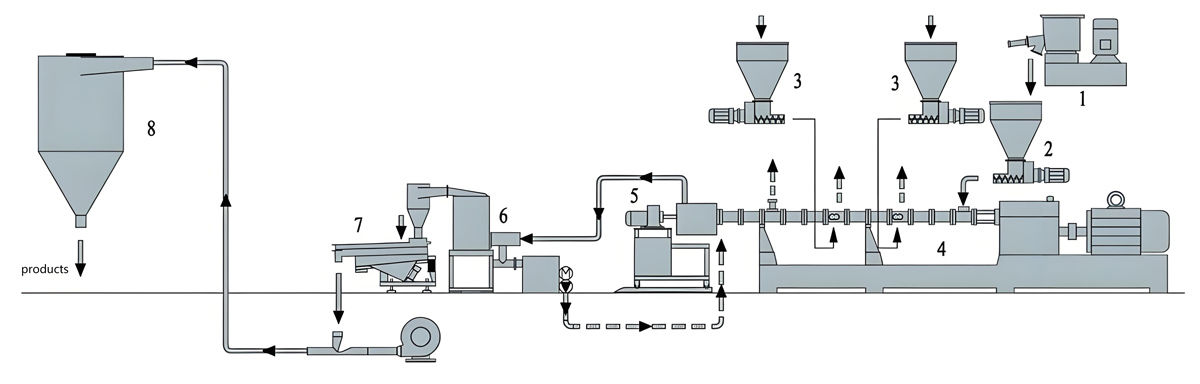

Production process of PVC masterbatch

The production process of PVC masterbatch mainly includes steps such as batching, mixing, extrusion, granulation, cooling, and packaging. The following is a specific introduction:

1. Ingredients: Accurately weigh various raw materials such as PVC resin, plasticizer, stabilizer, lubricant, filler, coloring agent, etc. according to the performance requirements of the product. For example, when producing soft PVC masterbatch, a large amount of plasticizer is added; When producing hard PVC masterbatch, less or even no plasticizers are added.

2. Mixing: Add the weighed raw materials into a high-speed mixer for thorough mixing. During the mixing process, the high-speed rotating stirring blade causes the materials to collide and rub against each other, achieving the goal of uniform dispersion. At the same time, appropriate processing aids can be added as needed during the mixing process to improve the processing performance of the material.

3. Extrusion: The mixed material enters the twin-screw extruder. The twin-screw extruder has good conveying capacity and mixing effect, which can fully melt and plasticize materials under high temperature and high pressure. During the extrusion process, the temperature, speed, pressure and other parameters of the extruder are controlled to ensure that the material reaches the optimal plasticization state. Generally speaking, the temperature of the extruder is set between 160 ℃ and 200 ℃, and the specific temperature is adjusted according to the type and formula of PVC resin.

4. Granulation: The material plasticized by the extruder is extruded from the machine head to form continuous strips or filaments. Then it is cut into granules of a certain length by a granulator, and common granulation methods include hot cutting and cold cutting. The hot cutting method is to use a rotating tool to cut the material into particles while extruding it, and the particle shape is relatively regular; The cold cutting method is to cool the extruded strip material first, and then cut it. This method is suitable for situations where particle shape requirements are not high.

5. Cooling: The PVC masterbatch after granulation needs to be cooled to prevent particle adhesion and deformation. Usually, air or water cooling is used for cooling. Air cooling is the process of using a fan to blow cold air towards particles, rapidly reducing their temperature; Water cooling is the process of cooling particles through a water tank, which has a better cooling effect. However, it is important to control the cooling rate to avoid internal stress on the particles.

6. Packaging: After cooling, the PVC masterbatch is sieved to remove particles that are too large or too small, and then packaged. Packaging usually uses plastic woven bags or paper bags to prevent moisture and contamination of the masterbatch. The product model, specifications, production date, and other information should be indicated on the packaging for storage and use purposes.

Main production machines

The main machinery and equipment for producing PVC masterbatch include the following:

Batching equipment

Electronic scale: used for precise weighing of various raw materials, such as PVC resin, plasticizers, stabilizers, fillers, etc. Its precision requirements are high, usually accurate to grams or even milligrams, to ensure the accuracy of ingredients.

Ingredient mixer: preliminary mixing and blending of various weighed raw materials to achieve a certain degree of uniform distribution before entering the high-speed mixer, thereby improving mixing efficiency.

Equipos de mezcla

High speed mixer: It is a key mixing equipment in the production of PVC masterbatch. It achieves highly uniform mixing of materials in a short period of time through high-speed rotating stirring blades. At the same time, appropriate liquid additives, such as plasticizer and lubricant, can be added as required during the mixing process, and can be evenly sprayed on the material surface through the spray device to achieve better mixing effect.

Equipos de extrusión

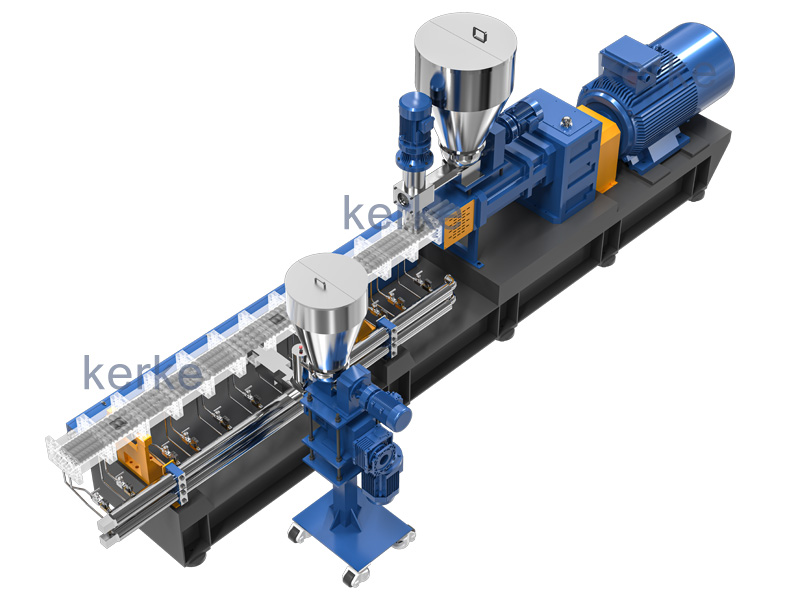

Twin screw extruder: This is one of the core equipment for PVC masterbatch production. It has two interlocking screws that transport, extrude, shear, and plasticize materials during rotation. The advantages of twin-screw extruder are strong conveying capacity, good mixing effect, high plasticizing quality, and the ability to adapt to the production of PVC masterbatch with different formulations and process requirements. It is also equipped with heating and cooling systems that can precisely control the temperature of the material during the extrusion process.

Equipos de granulación

Hot cutting granulator: For the production of PVC masterbatch with high requirements for particle shape and size, a hot cutting granulator is often used. It uses a rotating tool to cut the material into particles while it is extruded from the extruder head. The speed and cutting frequency of the cutting tool can be adjusted according to the required particle size, resulting in particles with regular shapes and uniform sizes.

Cold cutting granulator: The cold cutting granulator first cools and shapes the extruded strip material through a cooling device, and then performs cutting. This granulator is suitable for situations where the appearance of the particles is relatively low, but high production efficiency is required. Its structure is relatively simple and the maintenance cost is low.

Cooling equipment

Air cooling system: composed of fans, ducts, and cooling channels. When the PVC masterbatch after granulation passes through the cooling channel, the fan blows cold air into the channel to quickly dissipate the heat on the surface of the particles, achieving the purpose of cooling. The air-cooled system has the advantages of fast cooling speed and dry particle surface, and is suitable for situations where low moisture content is required for particles.

Water cooling system: mainly including water tank, water pump, and cooling pipeline. When particles pass through the water tank, they exchange heat with water to achieve rapid cooling. The cooling effect of the water cooling system is good, but attention should be paid to controlling the cooling speed to avoid internal stress caused by rapid cooling of particles. Meanwhile, the cooled particles need to undergo dehydration treatment to remove surface moisture.

Auxiliary equipment

Screening machine: used to screen the cooled PVC masterbatch, remove particles that are too large or too small, and ensure the uniformity of product particle size. Common screening machines include vibrating screens, rotating screens, etc. The appropriate type can be selected according to production scale and particle size requirements.

Packaging machine: Packaging the screened PVC masterbatch. Automatic packaging machines can achieve automation of packaging processes such as measurement, filling, and sealing, improving packaging efficiency and quality. Packaging machines are usually equipped with weighing devices that can accurately control the weight of each bag of product.

Related requirements

The production of PVC masterbatch requires the extruder to meet the following requirements:

Strict temperature control:

Temperature control is crucial in the production process of PVC masterbatch. The temperature of each heating zone of the extruder needs to be precisely adjusted according to the formula. Usually, the first zone is set at 160 ℃ to 170 ℃, the second zone at 170 ℃ to 180 ℃, the third zone at 180 ℃ to 190 ℃, and the head temperature is controlled at 190 ℃ to 200 ℃.

The operator needs to record temperature fluctuations every half hour. If the deviation exceeds ± 3 ℃, the machine should be stopped immediately for troubleshooting to prevent the decomposition of materials and the production of hydrogen chloride gas, which can corrode the equipment.

Reasonable screw design:

Screw design should follow the principle of low shear to prevent overheating. Screw and barrel require anti-corrosion treatment to extend the service life of the equipment.

The length to diameter ratio (L/D) of the screw is generally selected between 16~20, with a head taper of 20 °~30 °, which is more suitable for soft rubber. If the product requirements are high, a non metering section and separation type screw can be used, which is more suitable for hard PVC.

To cooperate with temperature control, cooling water or oil holes can be added inside the screw of the feeding section, and cold water or oil tanks can be added outside the barrel. The temperature control accuracy should be maintained at around ± 2 ℃.

Selection of extruder type:

The most commonly used extruders for the processing of PVC plastics are single screw extruders with equidistant and unequal depth gradient and equidistant and unequal depth gradient, as well as parallel twin-screw and conical twin-screw extruders with opposite rotation.

For the molding of hard PVC products such as PVC profiles/pipes, the conical twin-screw extruder has outstanding advantages and is the mainstream processing machine.

Matching screw speed with feeding speed:

The screw speed and feeding speed need to maintain dynamic balance. If the speed is too fast, it can lead to excessive shear heat and cause PVC thermal decomposition.

It is recommended to control the host current at 70%~85% of the rated value and maintain the torque within the range of 60%~75%. The speed of the feeding screw should match the main screw to ensure continuous and uniform feeding from the hopper, avoiding “hungry feeding” or “supersaturated feeding”.

Mold maintenance and process parameter control:

Mold maintenance directly affects the dimensional accuracy of the product. Preheat the mold to working temperature before daily production, and use an infrared thermometer to confirm the temperature uniformity of each part.

The lip gap of the mold needs to be adjusted according to the thickness of the product and checked at multiple points with a feeler gauge, with a tolerance controlled within ± 0.05mm.

Regularly dismantle the mold to clean the accumulated material, use a copper scraper with a special cleaning agent for treatment, and strictly prohibit the use of steel tools for scraping.

The various process parameters of the extruder need to be regularly checked to ensure the stability of the production process and the consistency of product quality.

Fórmula

The formula ratio of PVC masterbatch may vary depending on the performance requirements and application fields of the product. The following is a general range of ratios and typical formula examples for soft and hard PVC masterbatch:

Soft PVC masterbatch

General ratio range

PVC resin: 100 parts by mass, usually using PVC resin with a polymerization degree of 1000-1300 to ensure good processing performance and product flexibility.

Plasticizer: 30-80 parts, is a commonly used additive in soft PVC masterbatch, mainly used to increase the flexibility and plasticity of PVC. Common plasticizers include dioctyl phthalate (DOP), dibutyl phthalate (DBP), etc.

Stabilizer: 2-5 parts, used to prevent PVC from degrading due to factors such as heat and light during processing and use. Common stabilizers include lead salts, metal soaps, organotin compounds, etc.

Lubricant: 0.5-1.5 parts, can reduce the friction between materials and processing equipment, improve the flowability of materials, and prevent materials from sticking to the surface of equipment. Common lubricants include stearic acid, calcium stearate, paraffin wax, etc.

Filler: 0-30 parts, can reduce production costs while improving certain properties of the product, such as hardness, dimensional stability, etc. Common fillers include calcium carbonate, talc powder, kaolin, etc.

Typical formula example

PVC resin: 100 parts

DOP: 50 copies

Lead stearate: 2 parts

Stearic acid: 1 part

Calcium carbonate: 10 parts

Hard PVC masterbatch

General ratio range

PVC resin: 100 parts, generally using PVC resin with a polymerization degree of 800-1000 to achieve high rigidity and processability.

Stabilizer: 3-6 parts. Due to the high requirement for thermal stability during the processing of hard PVC masterbatch, the amount of stabilizer used is relatively large.

Lubricant: 0.8-1.2 parts, helps materials flow smoothly during processing, prevents mold sticking, and improves surface smoothness.

Fillers: 0-20 parts, added appropriately according to product performance requirements, used to improve product hardness, rigidity, and reduce costs.

Impact modifier: 5-15 parts, to improve the impact resistance of hard PVC and make it less prone to cracking during use. Common impact modifiers include chlorinated polyethylene (CPE), acrylic ester (ACR), etc.

Processing aids: 0.5-2 parts, improve the processing performance of PVC, promote material plasticization and flow. Common processing aids include ACR processing aids, etc.

Typical formula example

PVC resin: 100 parts

Tribasic lead sulfate: 3 parts

Dibasic lead phosphite: 2 parts

Calcium stearate: 0.8 parts

CPE: 8 copies

ACR processing aid: 1 part

Calcium carbonate: 5 parts

The above formula is for reference only. In actual production, adjustments and optimizations need to be made based on specific product requirements, processing techniques, and raw material characteristics.

Aplicaciones

PVC masterbatch has a wide range of applications in multiple fields, and the following are some of the main application aspects:

Pipe

Water supply pipe: PVC masterbatch has good corrosion resistance, water resistance, and hygiene performance. The produced water supply pipe is not easy to scale and can ensure stable water quality. It is widely used for the transportation of domestic water for urban and rural residents.

Drainage pipe: It has the advantages of light weight, easy installation, high drainage efficiency, and low cost, and is widely used in building drainage systems and urban drainage networks.

Wire conduit: PVC masterbatch produced wire conduit has good insulation performance, flame retardancy, pressure resistance and other characteristics, which can be used to protect wires and cables, and is widely used in building electrical installation engineering.

Profile

Door and window profiles: PVC masterbatch made door and window profiles have the advantages of beauty, good air and water tightness, thermal insulation, sound insulation, and noise reduction. They can effectively improve the energy-saving effect and living comfort of buildings, and are widely used in the field of building doors and windows.

Decorative profiles: can be processed into various shapes and colors of decorative lines, skirting boards, etc., used for indoor decoration, with good decorative and durability.

Film

Agricultural film: PVC agricultural film has good transparency, insulation, and weather resistance, which can effectively improve the yield and quality of crops. It is widely used in fields such as greenhouses and plastic film covering in agricultural planting.

Packaging film: PVC packaging film has the characteristics of high transparency, good barrier properties, and easy heat sealing. It can be used for packaging products such as food, medicine, and daily necessities, effectively protecting products and improving their aesthetics and added value.

Industrial film: In some industrial fields such as electronics, automobiles, etc., PVC film can be used for product protection, insulation, etc.

Injection molding products

Plastic toys: PVC masterbatch has good formability and flexibility, and can be made into various colorful and realistic plastic toys with relatively low cost.

Pipe fittings: Injection molded PVC pipe fittings have the advantages of high precision and good sealing, and are widely used in pipeline systems such as water supply and drainage, gas, etc.

Household items such as plastic hangers and storage boxes are also commonly made of PVC masterbatch injection molding, which has good durability and decorative properties.

Wire and cable

PVC masterbatch has good insulation and mechanical properties, and can be used as an insulation layer and sheath material for wires and cables. It can effectively protect the conductors inside wires and cables, prevent leakage and external factors from damaging them, and is widely used in the manufacturing of wires and cables in the fields of power, communication, etc.