PET masterbatch is usually a milky white or light yellow granular material with high glossiness and transparency. Its density is about 1.38-1.41g/cm ³, with good dimensional stability and mechanical strength. At the same time, it has excellent chemical corrosion resistance and can resist the erosion of most acids, alkalis, and organic solvents. But in high temperature and high humidity environments, hydrolysis reactions may occur. The melting point of PET masterbatch is relatively high, generally around 250-260 ℃, and it has good thermal stability. It can maintain good physical properties within a certain temperature range. Its glass transition temperature is about 70-80 ℃. PET masterbatch has good processing performance and can be processed into various plastic products through various molding processes such as extrusion, injection molding, blow molding, etc. During the processing, it is necessary to strictly control process parameters such as temperature and humidity to ensure product quality.

Production process of PET masterbatch

1. Raw material preparation:

Purified terephthalic acid (PTA): requires high purity and low impurity content, usually with a purity of 99.5% or higher. The quality of PTA directly affects the quality of PET masterbatch, and indicators such as carboxyl content and metal ion content need to be strictly controlled.

Ethylene glycol (EG): Purity is generally required to be above 99.8%, with low moisture content. Impurities in EG can affect the progress of the reaction and the performance of PET, such as aldehyde impurities that may cause branching or cross-linking of PET molecular chains.

Additives: Depending on product performance requirements, catalysts, stabilizers, matting agents, etc. may be added. The commonly used catalysts include antimony based, germanium based, and titanium based catalysts, such as antimony trioxide, with a typical addition amount of 200-500 ppm. Stabilizers can prevent thermal oxidative degradation of PET during processing and use, while matting agents such as titanium dioxide can reduce the glossiness of PET.

2. Esterification reaction:

Feed: Put PTA and EG in a certain molar ratio (usually 1:1.2-1:1.3) into the esterification reactor.

Heating and pressurization: Under stirring conditions, gradually raise the temperature to 220-260 ℃ while applying a pressure of 0.2-0.3MPa.

Reaction proceeds: PTA and EG undergo esterification reaction, producing dihydroxyethyl terephthalate (BHET) and water. During the reaction process, the generated water is continuously removed through a distillation device to promote the reaction towards the positive direction. The conversion rate of esterification reaction is usually required to reach over 95%.

3. Pre condensation reaction:

Transfer to the pre condensation kettle: After the esterification reaction is completed, transfer the reactants to the pre condensation kettle.

Reduce pressure: Gradually reduce the pressure inside the reaction vessel to 0.05-0.1MPa, while raising the temperature to 270-275 ℃.

Preliminary condensation: At lower pressure and higher temperature, BHET molecules begin to undergo condensation reactions, forming oligomers. The pre polymerization reaction time is generally 1-2 hours, at which point the intrinsic viscosity of the polymer reaches 0.2-0.4 dL/g.

4. Final condensation reaction:

Transfer to the final condensation kettle: Transfer the pre condensation product to the final condensation kettle.

High vacuum condensation: Further increase the reaction temperature to 275-280 ℃, while reducing the pressure inside the reaction vessel to a high vacuum state of 10-30Pa. Under high vacuum, the hydroxyl and carboxyl groups between oligomer molecules continue to undergo condensation reactions, causing the molecular chains to continuously grow and form high molecular weight PET.

Control reaction endpoint: The reaction endpoint is controlled by online detection of the intrinsic viscosity of the polymer. Generally, the intrinsic viscosity of PET masterbatch is required to be between 0.6-0.85dL/g. The final condensation reaction time is usually 2-4 hours.

5. Granulation:

Melt extrusion: The PET melt that meets the quality requirements is extruded from the bottom of the final condensation kettle and transported to the granulator through the melt pipeline.

Underwater or air-cooled granulation:

Underwater granulation: The melt is extruded into thin strips underwater through a die, and then cut into granules by a rotating cutter. The particles are cooled in water and transported to the dehydration and drying system. The particles produced by this method have regular shapes, smooth surfaces, and uniform particle sizes.

Air cooled pellet cutting: After the melt is extruded from the die, it is naturally cooled into strips in the air, and then cut into pellets by a cutting knife. The air-cooled granulation equipment is simple, but the particle surface may not be smooth enough and the particle size uniformity is relatively poor.

6. Post processing:

Drying: The PET masterbatch after granulation contains a certain amount of moisture and needs to be dried. The commonly used drying methods include hot air drying and dehumidification drying. The drying temperature is generally between 150-180 ℃, and the drying time is 3-8 hours to reduce the moisture content of the masterbatch to below 0.05%.

Screening: The dried mother particles are screened using equipment such as vibrating screens or rotating screens to remove oversized or undersized particles and possible impurities, ensuring uniform particle size distribution of the product.

Packaging: PET masterbatch that meets quality standards is packaged in plastic bags or ton bags to prevent moisture absorption and external contamination.

Classification

PET masterbatch can be classified into various types according to different classification criteria. The following are some common classification methods and specific types:

Classified by purpose

Fiber grade PET masterbatch: mainly used for the production of various polyester fibers, such as long and short fibers for textile and clothing, as well as high-strength yarns for industrial use. This type of masterbatch has strict requirements for molecular weight and its distribution, viscosity, and other indicators to ensure the strength, toughness, spinnability, and other properties of the fibers.

Bottle grade PET masterbatch: used for manufacturing packaging bottles, such as beverage bottles, food bottles, etc. Require the masterbatch to have high transparency, good barrier properties, low acetaldehyde content, and other characteristics to ensure the quality and safety of the packaging contents, while meeting the processing performance requirements of the preform.

Film grade PET masterbatch: used for producing various plastic films, including packaging films, electronic films, etc. Film grade PET masterbatch needs to have excellent tensile properties, optical properties, and thermal stability to meet the performance requirements of the film in processes such as stretching, printing, and lamination.

Engineering plastic grade PET masterbatch: used for manufacturing engineering plastic products such as electronic appliances and automotive components. This type of masterbatch usually requires the addition of various additives, such as reinforcing agents, flame retardants, toughening agents, etc., to improve its mechanical strength, heat resistance, flame retardancy, and other properties, meeting the requirements of engineering applications.

Classify based on characteristics

Conventional PET masterbatch: It has ordinary physical and chemical properties and meets the basic requirements for general use, such as the production of conventional fibers, films, bottle products, etc.

Modified PET masterbatch: By adding different additives or using special production processes, PET is modified to have special properties. Common types of modifications include:

Flame retardant PET masterbatch: Added flame retardant to give PET good flame retardant properties, widely used in fields such as electronics and automotive interiors that require fire safety.

Toughened PET masterbatch: Adding toughening agents to improve the toughness and impact resistance of PET, suitable for manufacturing products that require significant external forces.

Heat resistant PET masterbatch: After special treatment or the addition of heat-resistant additives, the thermal deformation temperature and thermal stability of PET are improved, making it suitable for applications in high-temperature environments.

Anti static PET masterbatch: Adding anti-static agents to reduce the surface resistance of PET and prevent static electricity accumulation. It is commonly used in electronic device packaging, film and other fields to avoid damage to products caused by static electricity.

Classify by color

White PET masterbatch: It is the most common color, with high transparency and good appearance, suitable for products with low color requirements or requiring subsequent dyeing, such as ordinary fiber, film, and bottle products.

Colored PET masterbatch: By adding color masterbatch or using special dyeing processes, various colors of PET masterbatch are produced, such as black, red, blue, etc. Colored PET masterbatch can be directly used to produce products with specific color requirements, reducing subsequent dyeing processes, improving production efficiency, and ensuring color uniformity and stability.

Fórmula

The formula ratios of different types of PET masterbatch may vary depending on the manufacturer and specific product requirements. The following are the approximate formula ratio ranges and main ingredient descriptions of some common types of PET masterbatch:

Fiber grade PET masterbatch

Main components and ratios:

Polyethylene terephthalate (PET): usually accounting for about 90% -99%, it is the main component of the masterbatch and determines the basic properties of the fiber, such as strength, melting point, chemical resistance, etc.

Additives: Overall accounting for 1% -10%. Including matting agents (such as titanium dioxide, usually added in an amount of 0.1% -2%), used to adjust the glossiness of fibers; Heat stabilizers (such as phosphate esters, added in an amount of about 0.1% -0.5%) are used to prevent PET from degrading due to high temperatures during processing; Lubricants (such as fatty acid esters, usually added in an amount of 0.1% -0.3%) improve the processing performance of fibers and reduce friction.

Bottle grade PET masterbatch

Main components and ratios:

PET: The content is generally around 98% -99.5%, requiring high purity and specific molecular weight distribution to ensure the processing performance of the preform and the physical properties of the bottle, such as transparency, strength, and barrier properties.

Additives: accounting for 0.5% -2%. Among them, acetaldehyde inhibitors (such as cobalt salts, manganese salts, etc., with an addition amount of about 0.01% -0.1%) are used to reduce the acetaldehyde content in bottle grade PET and prevent beverage and other packaging contents from being contaminated by acetaldehyde; Crystallization nucleating agents (such as sodium benzoate, usually added in an amount of 0.05% -0.2%) can accelerate the crystallization rate of PET, improve production efficiency and bottle quality.

Film grade PET masterbatch

Main components and ratios:

PET: Usually accounting for 97% -99%, there are strict requirements for its molecular weight and molecular weight distribution to ensure that the film has good tensile, optical, and mechanical properties.

Additives: accounting for 1% -3%. Including lubricants (such as oleic acid amide, etc., with a general addition amount of 0.05% -0.2%), reducing the friction coefficient of the film surface and preventing the film from sticking during winding and use; Anti adhesive agents (such as diatomaceous earth, with an addition amount of about 0.1% -0.5%) can improve the anti adhesive properties of the film, which is beneficial for the storage and transportation of the film; UV absorbers (such as benzophenones, usually added in an amount of 0.1% -0.3%) are used to prevent the film from aging due to UV exposure during outdoor use.

Flame retardant PET masterbatch

Main components and ratios:

PET: The basic content is generally around 70% -90%.

Flame retardants: The addition amount is usually 10% -30%. Commonly used flame retardants include phosphorus based flame retardants (such as phosphate esters), halogen based flame retardants (such as decabromodiphenyl ether, but their use is gradually limited due to environmental issues), and inorganic flame retardants (such as magnesium hydroxide, aluminum hydroxide, etc.). In order to improve the compatibility and dispersibility of flame retardants with PET, an appropriate amount of compatibilizer (such as maleic anhydride grafted polyethylene, etc., with an addition amount of about 1% -3%) is sometimes added.

Toughened PET masterbatch

Main components and ratios:

PET: The content is about 80% -95%.

Toughening agent: The addition amount is generally between 5% and 20%. Common toughening agents include ethylene octene copolymer (POE), nitrile rubber (NBR), thermoplastic polyurethane elastomer (TPU), etc. At the same time, in order to improve the interfacial adhesion between toughening agents and PET, some coupling agents (such as silane coupling agents, usually added in an amount of 0.5% -2%) may be added.

The above formula ratios are for reference only. In actual production, manufacturers will optimize and adjust based on specific performance requirements, production processes, and cost factors of the product.

Production equipment

The production process of PET masterbatch involves various machinery and equipment, and the following are the main production machines and their functions:

1. Reactor

Esterification reactor: It is the place where PTA and EG undergo esterification reaction. It is usually made of stainless steel material and has good corrosion resistance and sealing properties. It is equipped with a stirring device, heating system, feed inlet, discharge outlet, water separator, etc., to ensure that the reactants are fully mixed and uniformly heated, so that the esterification reaction can proceed smoothly.

Pre condensation reaction kettle: used for preliminary condensation reaction, with a structure similar to esterification reaction kettle, but with higher requirements for stirring intensity, temperature and pressure control accuracy to meet the conditions of pre condensation reaction and promote the formation of oligomers.

Final condensation reactor: It is a key equipment for forming high molecular weight PET. It is necessary to have high vacuum maintenance ability, precise temperature and stirring control to achieve deep condensation reaction and make PET molecular weight meet product requirements.

2. Heat exchanger

Esterification heat exchanger: used to control the reaction temperature during the esterification reaction process, by circulating heat medium or cooling water to regulate the temperature of the materials in the reaction kettle, ensuring that the esterification reaction proceeds within an appropriate temperature range.

Condensation heat exchanger: It plays a similar role in pre condensation and final condensation reactions, and can also be used to recover heat during the reaction process, improving energy utilization efficiency.

3. Fractionation tower: used to separate the water generated in the esterification reaction from the unreacted EG. Through the distillation action of the fractionation tower, the water is discharged from the top of the tower, and the EG is refluxed to the reaction kettle to continue participating in the reaction, in order to improve the conversion rate of the reaction.

4. Vacuum pump: During the pre condensation and final condensation reaction stages, a vacuum pump is required to reduce the pressure inside the reaction vessel, create a high vacuum environment, promote the discharge of small molecule by-products, and push the condensation reaction towards the direction of generating high molecular weight PET.

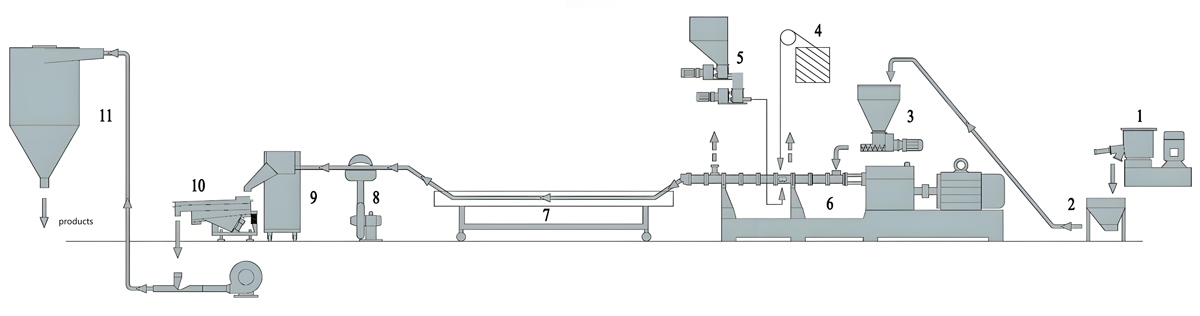

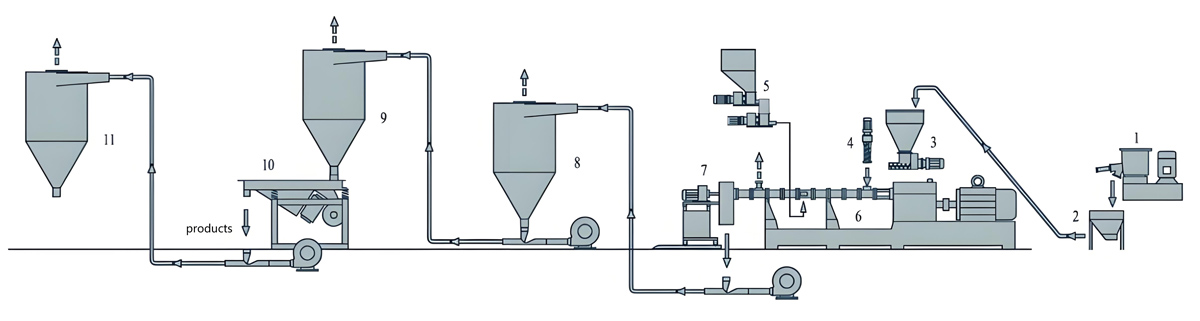

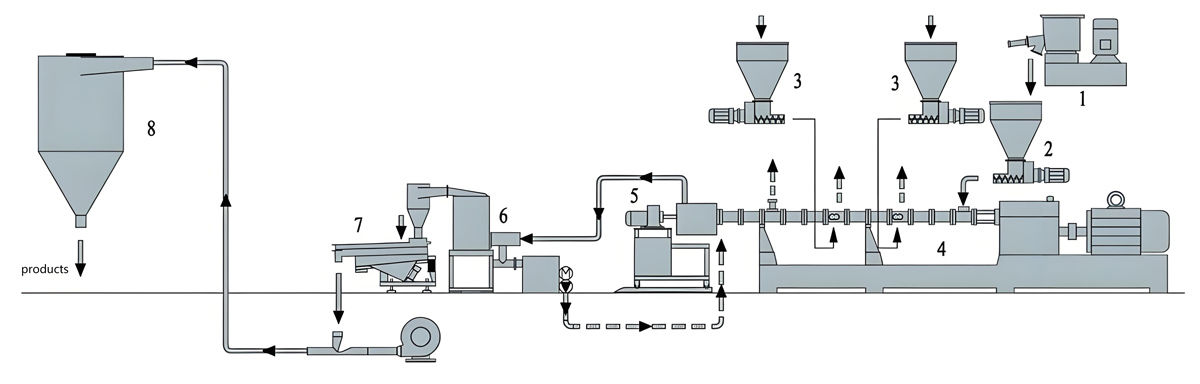

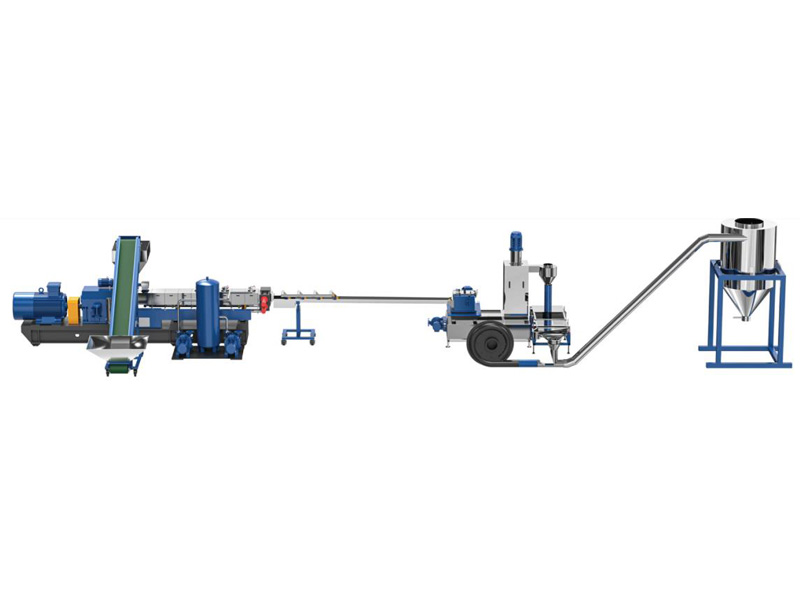

5. Granulator

Underwater granulator: composed of die head, cutter, water chamber, drying system, etc. After the PET melt is extruded from the die, it is cut into particles by a high-speed rotating cutter underwater. The particles are cooled in water and transported to a drying system to produce PET masterbatch with regular shape and smooth surface.

Air cooled granulator: mainly includes extrusion die, cutting device, and cooling air system. The molten material is naturally cooled into strips in the air after extrusion, and then cut into particles by a cutting knife. The structure of an air-cooled granulator is relatively simple, but the appearance and size uniformity of the particles are not as good as those of an underwater granulator.

6. Drying equipment

Hot air circulation dryer: uses circulating hot air to dry PET masterbatch. By heating the air to a certain temperature, it fully contacts with the masterbatch in the drying room and removes moisture. It has the advantages of uniform drying and easy temperature control, but the drying time is relatively long.

Dehumidification dryer: uses a desiccant to adsorb moisture from the air, providing low humidity dry air to dry the masterbatch. It can effectively reduce the moisture content of the masterbatch and has a higher drying efficiency, but the equipment and operating costs are relatively high.

7. Screening equipment

Vibration screen: By using a vibration motor to generate high-frequency vibration on the screen, the mother particles bounce on the screen, and are classified according to their size to screen out oversized or undersized particles and impurities, ensuring the uniformity of the product’s particle size.

Rotating sieve: using a rotating sieve cylinder for screening, the mother particles enter the sieve cylinder from the feeding port. During the rotation process, particles that meet the particle size requirements fall through the sieve holes, while those that do not meet the requirements are discharged from the other end. It is suitable for screening operations in large-scale production.

8. Measuring and conveying equipment

Measurement pump: used for precise measurement and transportation of PTA, EG and other raw materials as well as PET melt, ensuring that each raw material is accurately fed into the reaction kettle in a certain proportion, and the melt is stably transported in the pipeline.

Material conveying pipeline: made of materials such as stainless steel or polytetrafluoroethylene, with good corrosion resistance and wear resistance, used to connect various production equipment, achieve automated material conveying, and reduce errors and pollution caused by manual operation.

Pneumatic conveying system: using compressed air to transport PET masterbatch from the granulator to drying equipment, screening equipment or packaging equipment, it has the advantages of high conveying efficiency, cleanliness and hygiene, and is suitable for long-distance transportation of granular materials.

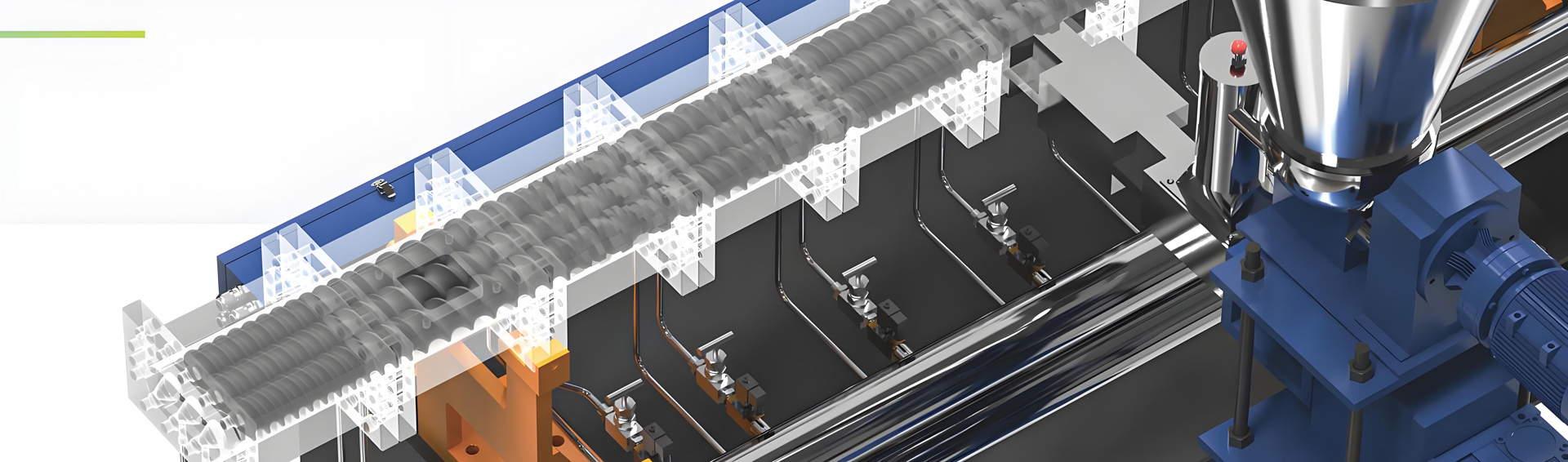

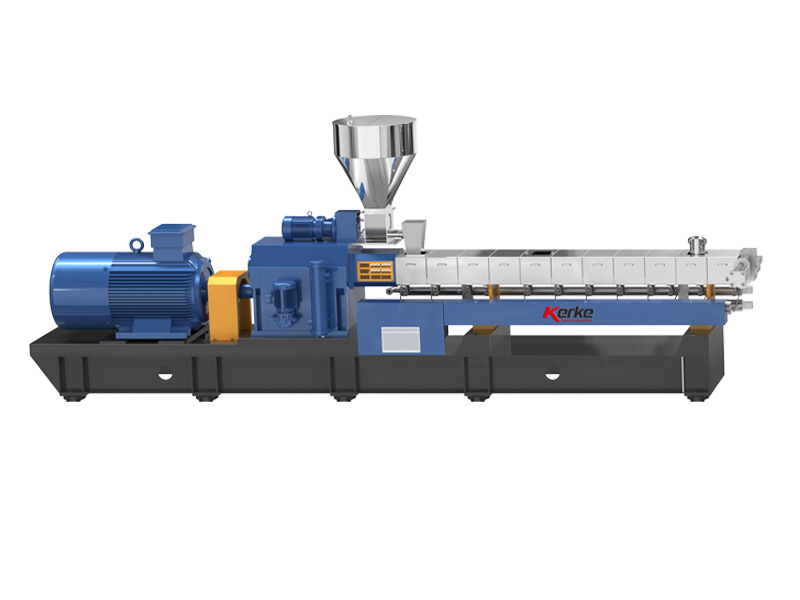

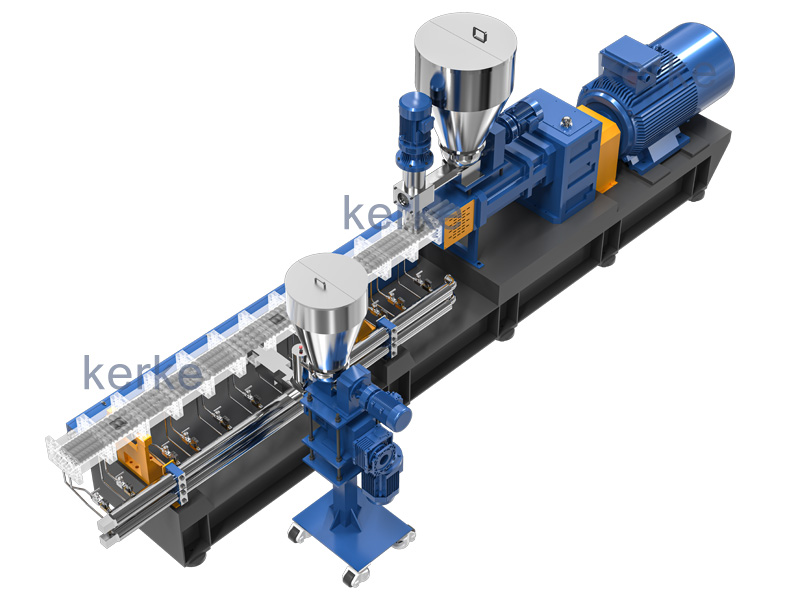

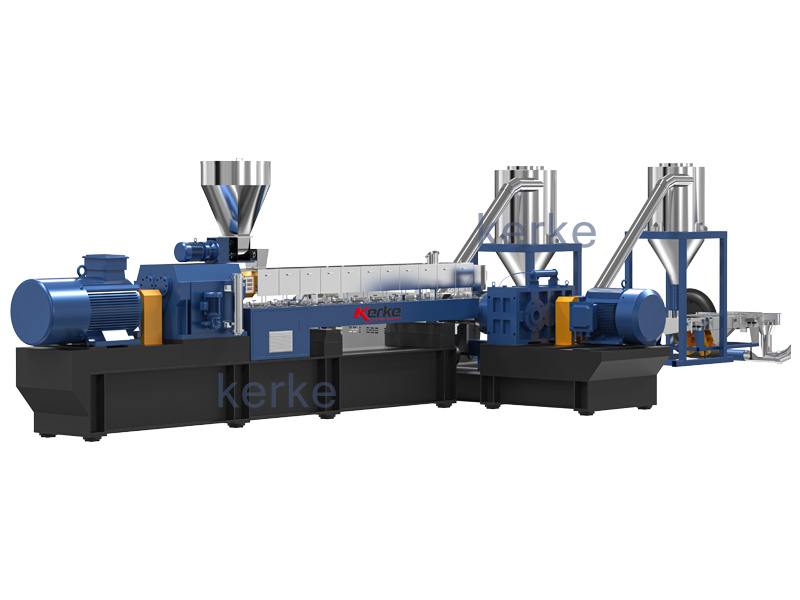

PET masterbatch extruder

Kerke’s masterbatch extruder can be used to produce PET masterbatch. Our PET masterbatch extruder has multiple models to choose from, which can meet different production requirements.

-

Extrusora de doble husillo para laboratorio

¿Cuándo necesitará una extrusora de doble husillo de laboratorio? Si desea realizar ensayos y pruebas de...

-

Extrusora de doble husillo paralelo

Nuestra extrusora de doble husillo paralelo corrotante está diseñada para la fabricación de compuestos y...

-

Extrusor triple (3 tornillos)

La extrusora de 3 tornillos es una nueva tecnología que tiene muchas ventajas. La extrusora de triple tornillo se utiliza principalmente...

-

Sistema de extrusión de doble etapa

El sistema de extrusión madre-bebé está diseñado para materiales especiales que no pueden procesarse en una extrusora de una etapa,...

-

Línea de amasado Banbury

Nuestra amasadora + extrusora está diseñada para realizar aplicaciones especiales con una capacidad de producción de 30kg/h a 1000kg/h....

-

Sistema de corte / Sistema de granulación

Diferentes materiales necesitan diferentes sistemas de corte, Kerke ofrece todo tipo de sistemas de corte, aquí está la explicación de...

Related requirements

The production of PET masterbatch requires the extruder to meet the following requirements:

Temperature control:

The melting temperature of PET particles should be controlled within the range of 240 ° C to 280 ° C, and heating should be as uniform as possible to avoid insufficient annealing or excessive extrusion caused by uneven heat distribution.

The extruder should be equipped with a high-precision temperature control system to ensure that the temperature of each heating section is stable and meets the process requirements.

Screw design:

The design of the screw should provide good plasticization and uniform melt flow. For PET materials, the aspect ratio and diameter of the screw need to be selected according to production requirements. Generally, larger screw diameters can handle more materials, but equipment volume and energy consumption will also increase.

The rotational speed of the screw also needs to be precisely controlled. A higher rotational speed can improve production efficiency, but it can also increase equipment wear and energy consumption, and may lead to excessive material shearing and heating.

Extruder type:

Twin screw extruders are commonly used in the production of PET masterbatch, especially co rotating twin screw extruders, due to their excellent mixing and plasticizing effects.

For specific production needs, such as high-yield or special performance PET masterbatch, it may be necessary to choose extruders with special screw structures or configurations.

Equipment performance and stability:

The extruder should have high torque and stable operating performance to ensure stable operation when processing PET materials with high viscosity or high filling volume.

The equipment should have good wear resistance and corrosion resistance to withstand high temperature, high pressure, and material friction.

Cooling system:

The extruder should be equipped with an effective cooling system to ensure that the PET melt can quickly cool and solidify after extrusion, maintaining the dimensional stability and surface quality of the product.

Other considerations:

The material barrel structure of the extruder should have good heating and cooling performance to ensure that the material can be processed within a suitable temperature range.

For the production of specific functional PET masterbatch (such as flame retardant, antibacterial, etc.), extruders may require special feeding systems or mixing devices to ensure uniform dispersion of functional additives.

Aplicaciones

PET masterbatch has excellent physical and chemical properties and is widely used in various fields. The following are some of the main application aspects:

Fiber field

Clothing and textile: PET masterbatch can be made into polyester fibers, which are used to produce various clothing fabrics. This type of fiber has the characteristics of being firm, wrinkle resistant, easy to wash and dry, and not deformed. It can also be blended with natural fibers to improve fabric performance, and is widely used in the production of shirts, jackets, sportswear, and more.

Home textile: In home textile products, PET fibers are used to manufacture bedding, curtains, sofa covers, etc. It can provide good warmth, softness, and wear resistance, making home textile products more durable and comfortable.

Industrial fibers: In the industrial field, PET fibers can be used to manufacture ropes, fishing nets, geotextiles, filter materials, etc. For example, geotextiles are used for reinforcement, isolation, and drainage in civil engineering, while filter materials are used for air and liquid filtration, utilizing the high strength, chemical resistance, and excellent filtration performance of PET fibers.

Campo de envasado

Bottle packaging: PET masterbatch is the main raw material for producing plastic bottles, especially for packaging beverages, food, cosmetics, and other products. PET bottles have the advantages of high transparency, good barrier properties, light weight, and resistance to breakage, which can effectively maintain the quality and taste of the contents, and are easy to recycle and reuse.

Film packaging: The PET film produced has excellent tensile strength, transparency, and glossiness, and can be used for food packaging, electronic device packaging, gift packaging, and more. At the same time, the performance of the film can be further improved through coating, composite and other processes to meet different packaging needs.

Engineering plastics field

Electronic appliances: PET masterbatch can be processed into engineering plastics, which are used to manufacture casings, components, etc. of electronic and electrical products. The casing of products such as televisions, computers, and mobile phones ensures their structural strength and safety by utilizing their excellent mechanical properties, insulation properties, and heat resistance.

Automotive components: In automotive manufacturing, PET engineering plastic can be used to produce instrument panels, door interior parts, engine covers, etc. It can reduce the weight of cars, improve fuel economy, and have good weather resistance and impact resistance.

Other areas

Medical field: PET material has biocompatibility and can be used to manufacture some medical products, such as medical sutures, artificial blood vessels, tissue engineering scaffolds, etc. After special treatment, PET fibers can also be used as wound dressings, with good breathability and water absorption.

In the field of optics, PET film can be used to manufacture optical components such as optical lenses, polarizers, and reflective films. Its excellent optical performance can meet the requirements of high-precision optical products and has important applications in fields such as liquid crystal displays and projectors.