HDPE masterbatch, also known as High Density Polyethylene Masterbatch, is an additive widely used in the field of plastic processing. It is mainly made of high-density polyethylene resin as the main substrate, and is processed through specific processes by adding pigments, additives, stabilizers, etc.

Proceso de producción

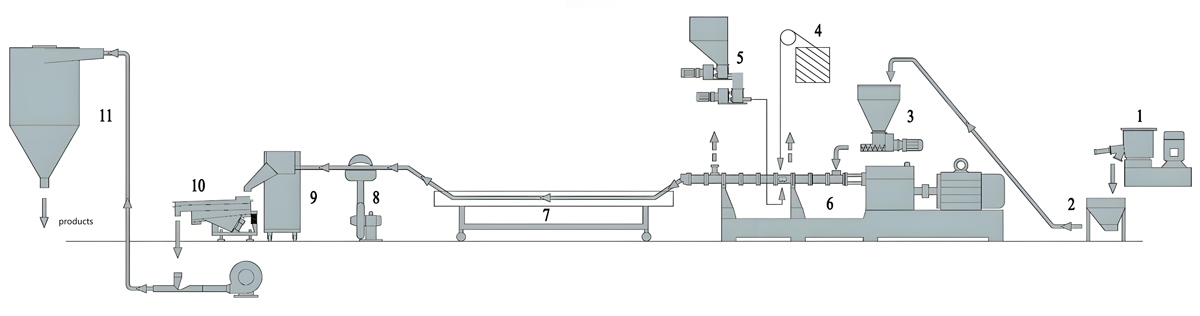

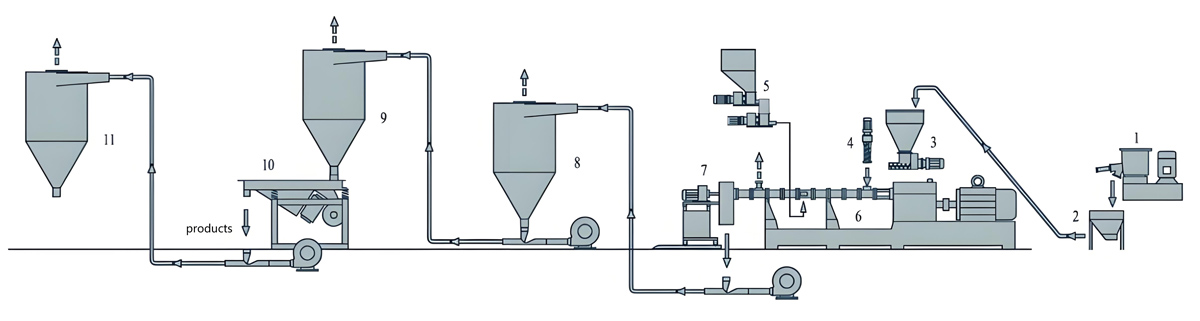

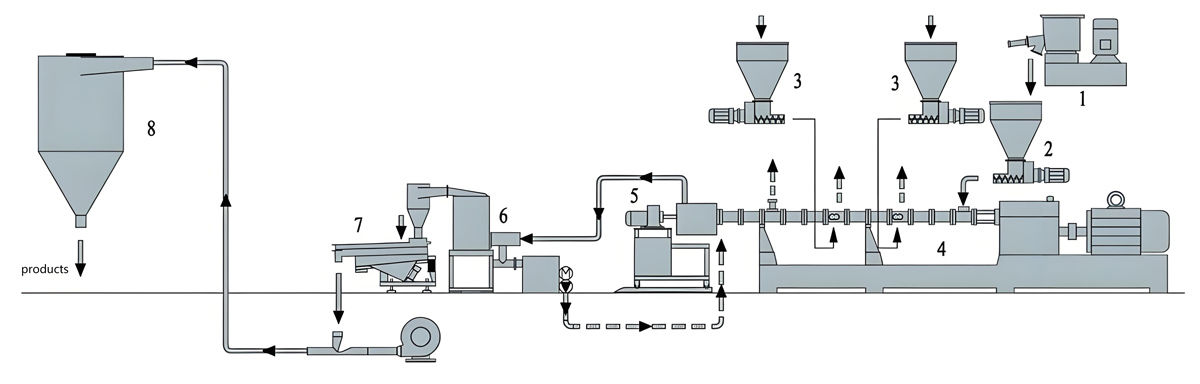

The production process of HDPE masterbatch mainly includes steps such as raw material preparation, mixing, melt extrusion, granulation, cooling and screening. The following is a specific introduction:

1. Preparación de la materia prima

HDPE resin: Select suitable high-density polyethylene resin as the basic raw material, and choose resins with different melt flow rates, densities, and other indicators according to product performance requirements.

Additives: Various additives are added according to the functional requirements of the masterbatch. For example, dispersants are added to improve the dispersibility of the masterbatch during processing; To prevent HDPE resin from aging due to factors such as light and heat during processing and use, antioxidants, light stabilizers, etc. need to be added.

Pigments or fillers: If producing color masterbatch, suitable pigments should be selected, which require good coloring power, weather resistance, heat resistance, etc; If producing functional masterbatch, such as filling masterbatch, it is necessary to prepare fillers such as calcium carbonate and talc powder.

2. Mezcla

Add HDPE resin, additives, pigments or fillers in a certain proportion to the high-speed mixer for thorough mixing. During the mixing process, a high-speed rotating stirring blade is used to create a complex flow state of the material inside the machine, achieving the goal of uniform dispersion of each component.

3. Melt extrusion

The mixed materials enter the extruder. The screw of the extruder pushes the material forward during the rotation process, and gradually heats the material to above the melting point of HDPE resin through a heating device, usually around 160-230 ℃, to completely melt the material. In the molten state, the material is subjected to the shear and extrusion of the screw, and the components are further uniformly mixed. Additives, pigments, or fillers are fully dispersed in the HDPE resin matrix.

4. Granulación

The molten material extruded through the die hole of the extruder head is usually in the form of strips or filaments. Cut it into granules of a certain length using granulation equipment such as hot cutting or cold cutting machines. The hot cutting machine is used to immediately cut the material into particles with a rotating cutting tool after the material is extruded from the mold hole, and the particle shape is relatively regular; The cold granulator first cools and solidifies the extruded strip material, and then cuts it into pellets.

5. Cooling and screening

The HDPE masterbatch after granulation needs to be cooled to prevent particle adhesion and deformation. The commonly used cooling methods include air cooling and water cooling. Air cooling uses air convection to remove heat from the surface of particles, while water cooling cools the particles through a water tank. The cooled particles are then sieved through a vibrating screen to remove particles that do not meet the required size, resulting in HDPE masterbatch products with uniform particle size.

6. Packaging

The qualified HDPE masterbatch after screening is usually packaged in plastic woven bags or composite packaging bags to prevent moisture and contamination during storage and transportation, which may affect product quality.

Different manufacturers may make appropriate adjustments and optimizations to their production processes based on their own equipment conditions, product requirements, etc., but the overall production process and key steps are basically similar.

Production machine

The main machinery and equipment for producing HDPE masterbatch include the following:

mixing equipment

High speed mixer: used to thoroughly mix raw materials such as HDPE resin, additives, pigments, or fillers. It achieves uniform mixing of materials in a short period of time through high-speed rotating stirring blades, laying the foundation for subsequent processing.

extrusion equipment

Single screw extruder: With a relatively simple structure, it is suitable for the production of HDPE masterbatch with low mixing requirements and small output. It consists of screws, barrels, heating devices, transmission systems, and other components. The screw rotates inside the barrel, pushing the material forward and gradually heating and melting it, and extruding it through the die hole of the machine head.

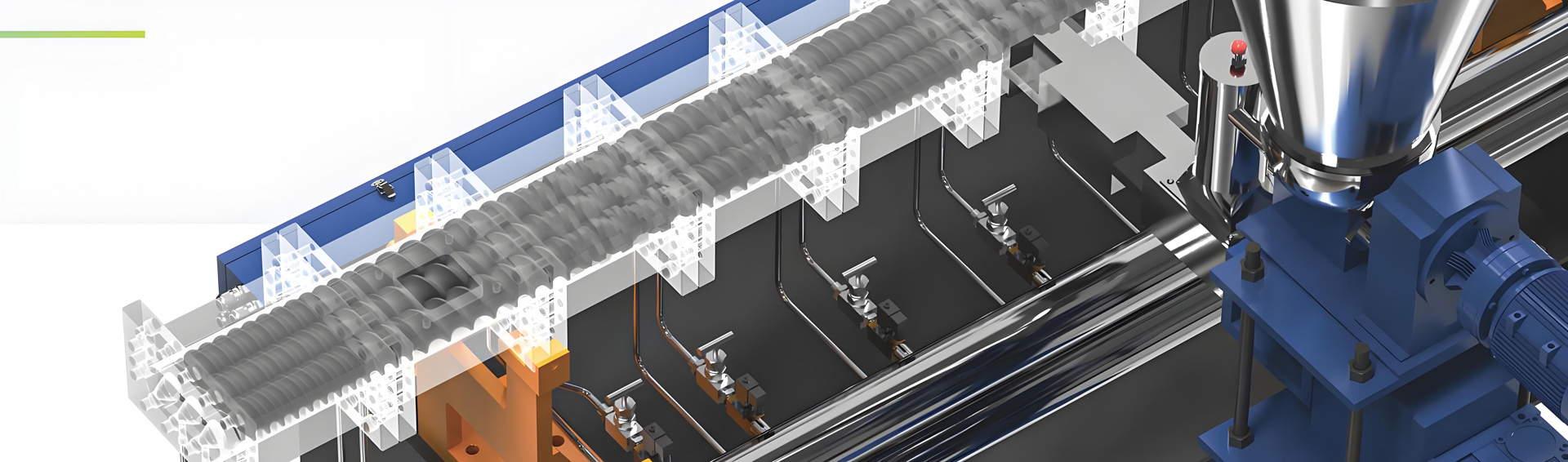

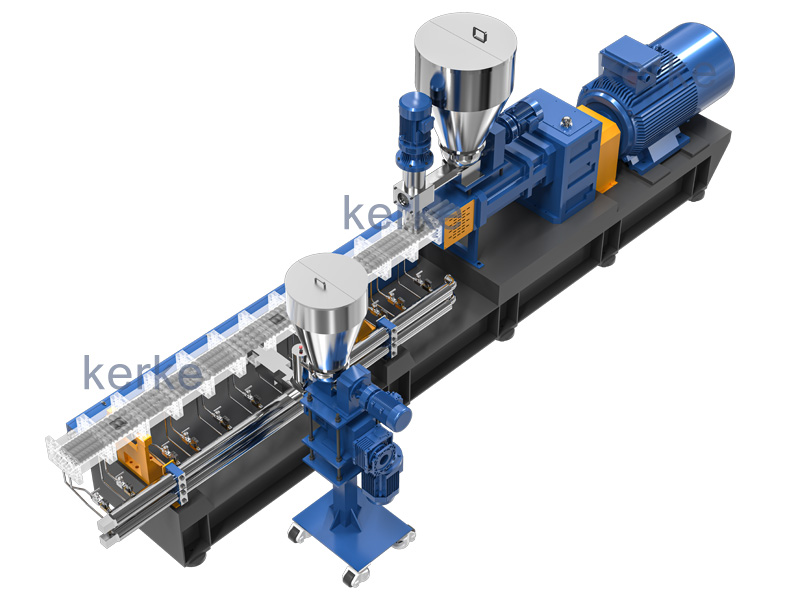

Twin screw extruder: With better mixing, dispersing, and conveying capabilities, it is commonly used to produce high-quality and high-performance HDPE masterbatch. The two screws of a twin-screw extruder mesh with each other, generating strong shear and extrusion effects on the material during rotation, which can evenly disperse additives, pigments, etc. in HDPE resin. At the same time, it can more accurately control the residence time and processing temperature of the material, and improve the stability of product quality.

Equipos de granulación

Hot cutting machine: Generally used in conjunction with an extruder, after the extruded molten material is extruded from the die hole of the machine head, it is immediately cut into particles using a high-speed rotating tool. This granulation method has high production efficiency, regular particle shape, smooth surface, and is suitable for the production of most HDPE masterbatch.

Cold cutting machine: First, the extruded strip material is cooled and solidified by a cooling device, and then cut into particles using a cutting tool. The cold granulator is suitable for the production of special HDPE masterbatch with high requirements for particle shape and size accuracy, such as high-precision functional masterbatch or color masterbatch with strict requirements for particle appearance quality.

cooling equipment

Air cooling system: composed of fans, air ducts, etc., it uses forced air flow to quickly dissipate the heat on the surface of the hot HDPE masterbatch into the air, achieving cooling. The air-cooled system has a simple structure, low cost, and is suitable for situations where cooling speed requirements are not particularly high.

Water cooling system: usually includes a water tank, circulating water pump, cooling water pipeline, etc. When the masterbatch passes through the water tank, it undergoes heat exchange with water, resulting in rapid cooling. The water cooling system has high cooling efficiency, but attention should be paid to controlling the cooling water temperature and quality to prevent water stains or other quality problems on the surface of the masterbatch.

screening equipment

Vibration screen: Using the vibration generated by the vibration motor, the mother particles are made to move back and forth on the screen, thereby separating mother particles of different sizes. Particles larger than the sieve size are left on the sieve, while particles that meet the particle size requirements fall into the collection container through the sieve holes. The vibrating screen has the advantages of high screening efficiency, high precision, and simple structure, and is a commonly used screening equipment in the production of HDPE masterbatch.

Packaging Equipment

Automatic packaging machine: capable of automatically completing packaging processes such as measurement, filling, and sealing. It can accurately pack HDPE masterbatch into packaging bags and seal them according to the set packaging weight or quantity, improving packaging efficiency and quality, and reducing manual operation errors. Common types include vertical automatic packaging machines and horizontal automatic packaging machines, which can be selected according to production scale and packaging requirements.

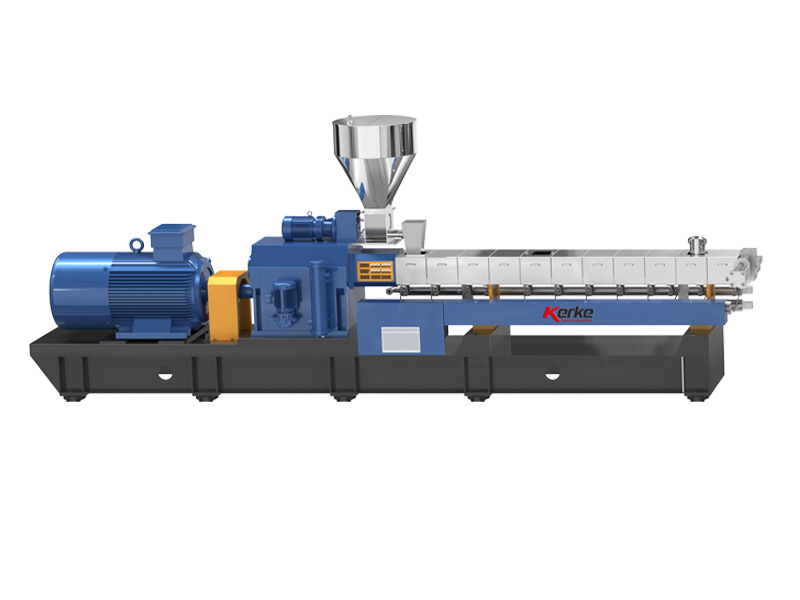

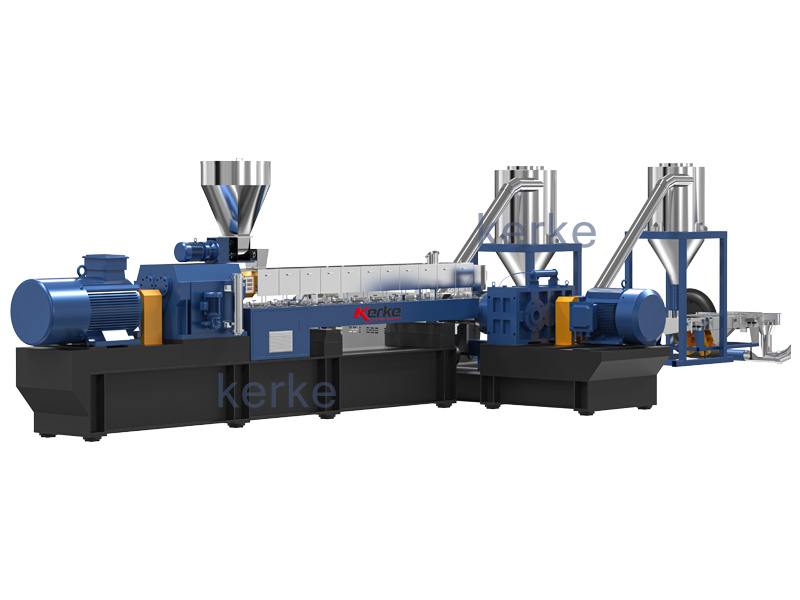

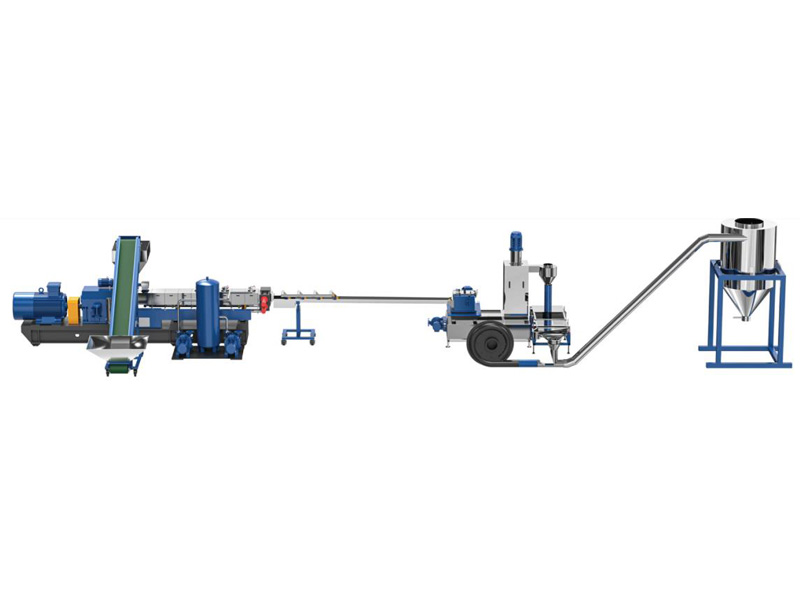

HDPE masterbatch extruder

Kerke’s masterbatch extruder can be used to produce HDPE masterbatch. Our HDPE masterbatch extruder has multiple models to choose from, which can meet different production requirements.

-

Extrusora de doble husillo para laboratorio

¿Cuándo necesitará una extrusora de doble husillo de laboratorio? Si desea realizar ensayos y pruebas de...

-

Extrusora de doble husillo paralelo

Nuestra extrusora de doble husillo paralelo corrotante está diseñada para la fabricación de compuestos y...

-

Extrusor triple (3 tornillos)

La extrusora de 3 tornillos es una nueva tecnología que tiene muchas ventajas. La extrusora de triple tornillo se utiliza principalmente...

-

Sistema de extrusión de doble etapa

El sistema de extrusión madre-bebé está diseñado para materiales especiales que no pueden procesarse en una extrusora de una etapa,...

-

Línea de amasado Banbury

Nuestra amasadora + extrusora está diseñada para realizar aplicaciones especiales con una capacidad de producción de 30kg/h a 1000kg/h....

-

Sistema de corte / Sistema de granulación

Diferentes materiales necesitan diferentes sistemas de corte, Kerke ofrece todo tipo de sistemas de corte, aquí está la explicación de...

Related requirements

The production of HDPE masterbatch requires the following specifications for the extruder:

Screw speed:

HDPE has slightly poor adaptability to high screw speeds, as excessive speeds can lead to uneven plasticization and material overheating. The suitable screw speed is usually in the range of 20-60 rpm.

Temperature control:

The processing temperature range of HDPE is wide, but precise control is required to ensure plasticizing quality and product stability. The extrusion temperature usually needs to reach between 180 ℃ and 230 ℃ to ensure that HDPE is fully melted, but it cannot be too high to degrade the material.

The extruder should be equipped with an effective temperature control system to ensure that the temperature settings of each heating section (such as the barrel and head) meet the process requirements and avoid incomplete plasticization caused by local low temperatures.

Screw design:

The design of the screw should provide good plasticization and uniform melt flow. For HDPE, deep groove and high compression ratio screws are usually used to optimize melt quality and extrusion efficiency.

The aspect ratio and diameter of the screw need to be selected according to production requirements. For products such as large-diameter pipes, larger diameter and longer aspect ratio screws may be required.

Extruder type:

Single screw extruder is the most widely used equipment in the processing of polyethylene pipes, and is also suitable for the production of HDPE masterbatch.

For large-diameter HDPE pipes or high production demand, it may be necessary to use a double stage screw structure or a specially designed single screw extruder to increase extrusion capacity and plasticization effect.

Equipment maintenance and operation:

The extruder should be regularly cleaned of the screw and barrel to avoid residue affecting the plasticization quality and product stability.

Operators should receive appropriate training to understand the characteristics of HDPE and the requirements of extrusion processes, in order to ensure the smooth progress of the production process.

Other considerations:

The driving power of the extruder should be large enough to ensure stable operation at high extrusion rates.

The cooling system should be able to effectively cool the molten HDPE to ensure the dimensional stability of the product and reduce warping.

Type

HDPE masterbatch can be divided into the following main types based on their functions and uses:

Masterbatch

Pigment type masterbatch: It is composed of pigments, dispersants, and HDPE carrier resins. By selecting different colors of pigments, various colored HDPE products can be produced. During the plastic processing, color masterbatch can be evenly dispersed in HDPE resin, resulting in stable and bright colors for the product. Widely used in plastic films, pipes, injection molded products and other fields, providing rich color choices for products.

Dye type masterbatch: Unlike pigment type masterbatch, dye type masterbatch uses dye as a coloring agent. Dyes have better transparency and glossiness, which can make HDPE products present bright and vibrant color effects. Commonly used for plastic products that require high color transparency and glossiness, such as transparent plastic containers, toys, etc.

Functional masterbatch

Anti aging masterbatch: additives such as antioxidant and light stabilizer are added to improve the aging resistance of HDPE products to light, heat, oxygen and other factors during long-term use. For HDPE plastic products used outdoors, such as agricultural film, geotextile, etc., adding anti-aging masterbatch can extend their service life and maintain the stability of product performance.

Antistatic masterbatch: Contains anti-static agents that can impart a certain level of conductivity to the surface of HDPE products, making them less prone to static electricity accumulation during production and use. Commonly used in the packaging materials, plastic films, and other fields of electronic and electrical products to prevent static electricity from damaging the products or causing safety accidents.

Flame retardant masterbatch: Added flame retardant to make HDPE products flame retardant, which can effectively prevent the spread of flames. Widely used in fields with high fire safety requirements such as building materials, wires and cables, it can improve the fire resistance of products and reduce fire risks.

Smooth masterbatch: Adding a smooth agent can reduce the friction coefficient on the surface of HDPE products, making them have good smooth performance. It is widely used in the production of plastic film, which can prevent adhesion between films, facilitate processing and use, and also improve the opening and packaging efficiency of films.

Fill masterbatch

Calcium carbonate filled masterbatch: made with calcium carbonate as the main filler, added with an appropriate amount of dispersant and HDPE carrier resin. Adding calcium carbonate filled masterbatch to HDPE plastic products can reduce the cost of the product, while also improving its hardness, rigidity, and dimensional stability. Commonly used in fields such as plastic pipes and injection molded products.

Talc powder filled masterbatch: Using talc powder as a filler, it has good insulation, heat resistance, and chemical stability. Adding talc powder to HDPE plastic filling masterbatch can improve the rigidity, heat resistance, and surface glossiness of the product, and is widely used in fields such as wire and cable, automotive parts, etc.

Kaolin filled masterbatch: Kaolin has good dispersibility and adsorption properties. Adding it to HDPE masterbatch can improve the processing and physical properties of plastic products. Applied in plastic films, pipes and other products, it can improve the barrier performance and printing performance of the products.

Formula ratio of different types of HDPE masterbatch

Different types of HDPE masterbatch have different formulas and ratios due to their different functions and uses. The following are typical proportioning ranges for some common types of HDPE masterbatch, which can be adjusted according to specific product requirements and production processes in actual production.

Masterbatch

Pigment type masterbatch

Pigments: usually accounting for 10% -30%, the specific amount depends on the depth of the desired color and the coloring power of the pigment. For example, when producing light colored products, the amount of pigment used may be between 10% and 15%; The production of dark colored products, such as black, dark blue, etc., can require a pigment dosage of up to 20% -30%.

Dispersant: generally accounting for 5% -10%, its function is to help the pigment disperse evenly in HDPE carrier resin, improve the quality and stability of color masterbatch.

HDPE carrier resin: The remaining amount is HDPE carrier resin, usually accounting for 60% -85%. The selection of carrier resin should match the HDPE raw material used to ensure good compatibility between the color masterbatch and the matrix resin.

Dye type masterbatch

Dyes: The dosage is generally between 5% and 20%. Due to the strong coloring power and high transparency requirements of dyes, the dosage is relatively small compared to pigment type masterbatch. For example, when producing light colored transparent products, the amount of dye used may be between 5% and 10%; When producing transparent products with bright colors, the amount of dye can be appropriately increased to 10% -20%.

Dispersant: accounting for 3% -8%, used to improve the dispersibility of dyes in carrier resins and ensure the stability of color masterbatch performance.

HDPE carrier resin: accounting for 72% -92%. As a carrier for dyes, it is required to have good transparency and processing performance to ensure the color effect and quality of the product.

Functional masterbatch

Anti-aging masterbatch

Antioxidants: generally accounting for 0.5% -2%, different types of antioxidants such as hindered phenols, hypophosphite esters, etc. are selected according to the usage environment and requirements of HDPE products to improve the antioxidant performance of the products.

Light stabilizer: The dosage is usually between 0.5% and 3%. Common light stabilizers include UV absorbers, hindered amine light stabilizers, etc., which can effectively absorb or quench UV rays and prevent HDPE products from aging under light.

HDPE carrier resin: The remaining amount is HDPE carrier resin, accounting for 95% -99%. The carrier resin is required to have good stability and processing performance in order to evenly disperse antioxidants and light stabilizers into HDPE products.

Antistatic masterbatch

Antistatic agent: accounting for 5% -15%, the type and amount of anti-static agent depend on the required anti-static performance of the product. Common anti-static agents include quaternary ammonium salts, polyethylene glycol, etc. They can form a conductive layer on the surface of HDPE products, reduce surface resistance, and achieve anti-static purposes.

Dispersant: accounting for 3% -8%, it helps the anti-static agent to be evenly dispersed in the carrier resin, improving the stability and effectiveness of the anti-static masterbatch.

HDPE carrier resin: accounting for 77% -92%. As a carrier for anti-static agents, it should have good compatibility with HDPE matrix resin to ensure that anti-static masterbatch can be uniformly integrated into HDPE products during processing.

Flame retardant masterbatch

Flame retardant: accounting for 20% -60%, suitable flame retardants should be selected according to the flame retardant grade requirements of HDPE products, such as halogen flame retardants, phosphorus flame retardants, aluminum hydroxide, etc. For products with high flame retardant requirements, the amount of flame retardant may be between 40% and 60%; For products with general flame retardant requirements, the amount of flame retardant can be between 20% and 40%.

Synergistic agent: The dosage is generally between 2% and 10%. Synergistic agents can work synergistically with flame retardants to improve flame retardancy and reduce the amount of flame retardants used. Common synergists include antimony trioxide.

HDPE carrier resin: accounting for 30% -78%. As a carrier for flame retardants and synergists, the carrier resin is required to have good processing performance and thermal stability to ensure the stability and dispersion of flame retardant masterbatch during processing.

Fill masterbatch

Calcium carbonate filled masterbatch

Calcium carbonate: accounting for 50% -80%, the particle size and surface treatment of calcium carbonate will affect the performance of the filling masterbatch. Generally speaking, the smaller the particle size, the better the filling effect, but the processing difficulty also increases accordingly. The compatibility between surface treated calcium carbonate and HDPE carrier resin is better, which can improve the quality of filling masterbatch.

Coupling agent: accounting for 1% -3%, used to improve the interfacial bonding between calcium carbonate and HDPE carrier resin, and enhance the performance of filling masterbatch.

Dispersant: accounting for 2% -5%, helps to evenly disperse calcium carbonate in the carrier resin and prevent agglomeration.

HDPE carrier resin: accounting for 15% -47%. As a carrier for calcium carbonate, it is required to have good flowability and processability, so that the calcium carbonate can be evenly dispersed into HDPE products during the processing.

Talc powder filled masterbatch

Talc powder: accounting for 40% -70%, the sheet-like structure of talc powder enables it to improve the rigidity and heat resistance of HDPE products. The dosage depends on the performance requirements of the product. Generally speaking, for products with high rigidity and heat resistance requirements, the dosage of talcum powder can be between 60% and 70%; For products with higher performance requirements, the amount of talcum powder can be appropriately reduced to 40% -60%.

Coupling agent: accounting for 1% -3%, used to enhance the bonding force between talc powder and HDPE carrier resin, and improve the performance of filling masterbatch.

Dispersant: accounting for 2% -5%, it helps to evenly disperse talc powder in the carrier resin, improving the quality and stability of the filling masterbatch.

HDPE carrier resin: accounting for 35% -67%. As a carrier for kaolin, it should have good fluidity and compatibility with kaolin to ensure the uniform distribution and performance of filling masterbatch in HDPE products.

Aplicación

HDPE masterbatch has a wide range of applications in multiple fields, and the following are some of the main application aspects:

plastic film

Agricultural film: used for producing agricultural film, such as greenhouse film, plastic film, etc. HDPE masterbatch can provide good weather resistance, aging resistance and mechanical strength, so that the agricultural film has a long service life, can effectively maintain soil temperature and humidity, and promote crop growth.

Packaging film: In the field of packaging, it can be used to manufacture various plastic packaging films, such as garbage bags, shopping bags, cling film, etc. HDPE masterbatch can endow the film with good toughness, puncture resistance, and moisture resistance, ensuring the reliability and practicality of packaging.

Plastic pipes

Water supply pipe: It is an important raw material for producing HDPE water supply pipes. HDPE pipes with added relevant masterbatch have the advantages of corrosion resistance, wear resistance, smooth inner wall, and low water flow resistance, which can ensure that water quality is not polluted. They are widely used in urban water supply, building water supply and drainage, and other fields.

Drainage pipes: used for manufacturing drainage pipelines, such as urban drainage networks, building drainage risers, etc. HDPE masterbatch can make pipes have good chemical corrosion resistance and impact resistance, and can adapt to different soil environments and usage conditions.

productos de moldeo por inyección

Plastic containers: can be used to produce various plastic containers, such as plastic buckets, plastic boxes, plastic pots, etc. HDPE masterbatch can endow containers with good rigidity, toughness, and chemical corrosion resistance, meeting the storage and transportation needs of different items.

Plastic toys: In the manufacturing of plastic toys, HDPE masterbatch can provide rich color choices and good molding performance, giving toys a bright appearance and high safety.

Productos de fibra

Geotextile: Used in the production of geotextiles, this geotextile has good permeability, filtration, and corrosion resistance, and is widely used in engineering fields such as water conservancy, transportation, and environmental protection, such as reinforcement, anti-seepage, and filtration of dams, roads, airports, etc.

Rope and fishing net: Fibers made from HDPE masterbatch have high strength, wear resistance, and resistance to seawater corrosion, and can be used to manufacture ropes, fishing nets, etc. They have important applications in the fields of fisheries and navigation.

Other areas

Wire and cable: As the sheath material of wire and cable, HDPE masterbatch can provide good insulation performance, weather resistance, and mechanical protection performance, ensuring the safe operation of wire and cable in different environments.

Foam plastic: It can be used to produce HDPE foam plastic. This kind of foam plastic has the properties of light weight, heat insulation, sound insulation, buffering, etc. It is widely used in packaging, building insulation, automobile interior decoration and other fields.